In this blog post I will share a very simple method of sleeve pattern drafting and walk you through how to draft a sleeve pattern that creates a basic sleeve block that fits any bodice block or sewing pattern you already own; making this a great beginner sleeve pattern tutorial. I will be using the basic bodice block pattern that I showed you how to create in my earlier blog post, however you can use any block or sewing pattern.

The post will include valuable tips and tricks, and an easy to follow 5 step method to achieve the perfect fit .

Tools and materials needed for sleeve block drafting

These are the tools I use for sleeve pattern drafting and creating a basic sleeve block.

- A piece of paper that is large enough to include the pattern. To paper should be the length of your upper arm length plus extra 5-8 cm. A1 sheet of paper is perfect option but you can stick together multiple sheets of paper with tape or use wrapping paper or a roll of brown crafts paper.

- Sharp pencil

- Pencil eraser (trust me, you are going to make a few mistakes. Even I do them when I let my mind wander).

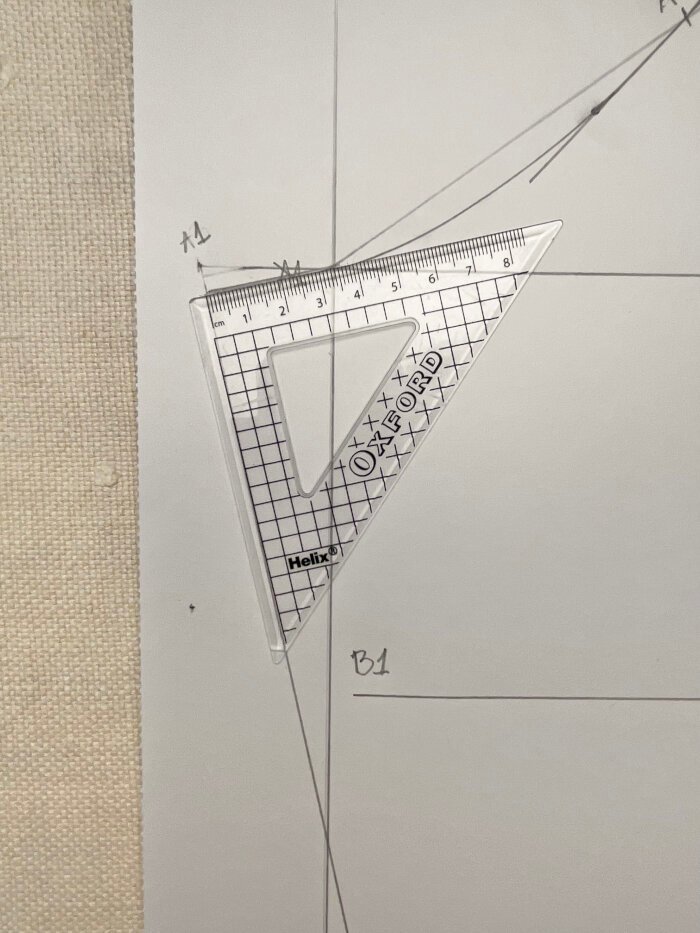

- Square ruler (a small triangle ruler from a typical Maths set is fine).

- A long ruler. Longer the better. The one I use are around 60 cm long. You can get away with shorter ones but you will need to be very careful ensuring that the lines are still straight.

- French curve

- Protractor (does it feel like geometry class yet? 😀 )

- Tape measure.

- Tracing wheel (optional, but super handy if you have it).

- Completed list of your sleeve measurements. I have a separate blog post dedicated to measurements and how to take them accurately by yourself, with a free template and guide)

Measurements required for basic sleeve pattern drafting

These measurements are essential for an accurate sleeve drafting method that fits smoothly into the armscye.

- Upper arm’s length

- Lower arms’s length

- Wrist circumference

- Bicep circumference

- Wrist to elbow

- Elbow circumference

- Wrist to Bicep

- the length of the armscye (taken from the bodice block)

How to measure armscye length

This sleeve block tutorial works with any bodice block, but the armscye measurement must be taken correctly. Before you use your bodice block, make sure that the block does not include any seam allowance. If it does include seam allowance, mark the seam on the pattern by measuring the seam allowance from the edge of the pattern. Take the armscye measurement along the created seam line.

My basic bodice block that I drafted in my other blog post does not include the seam allowance so I will measure along the edge of the basic block. First measure the armscye on the back bodice by placing the edge of the tape measure along the armhole. Repeat with the front bodice. Add these measurements to your measurement list for this project.

I recommend to keep the sleeve measurements in front of you while you are working on sleeve pattern drafting for ease of reference.

Step 1 – Draft the guide for height and width of the sleeve pattern

We start the sleeve pattern drafting process by defining the height and width of the basic sleeve block.

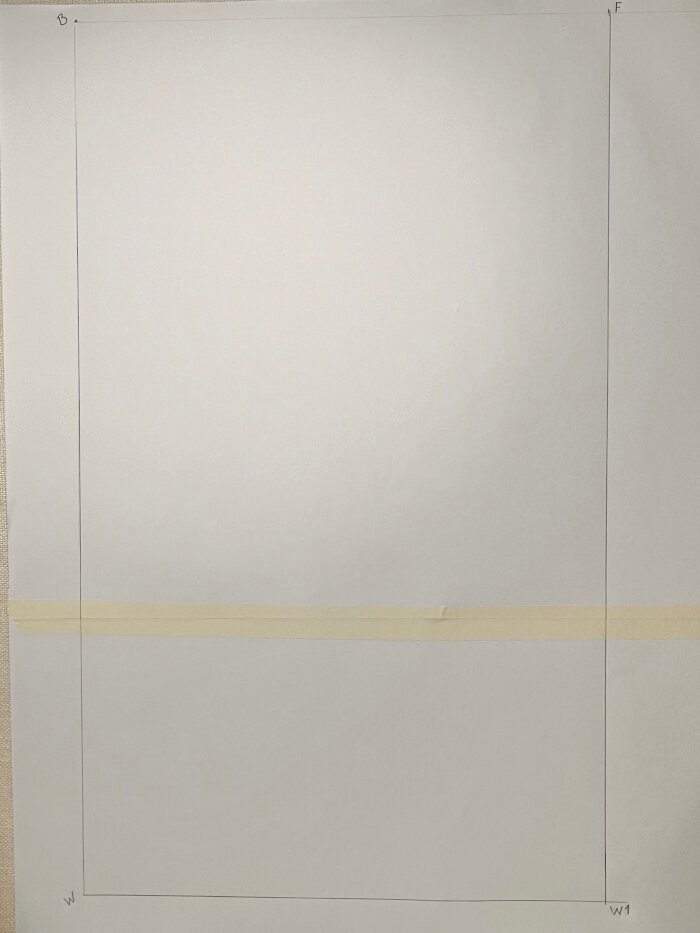

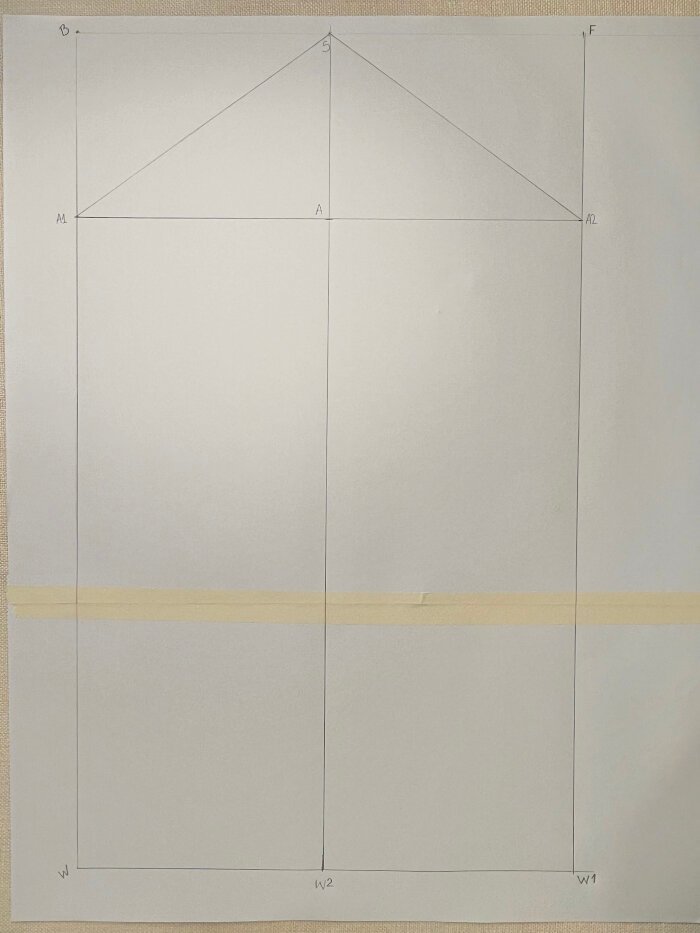

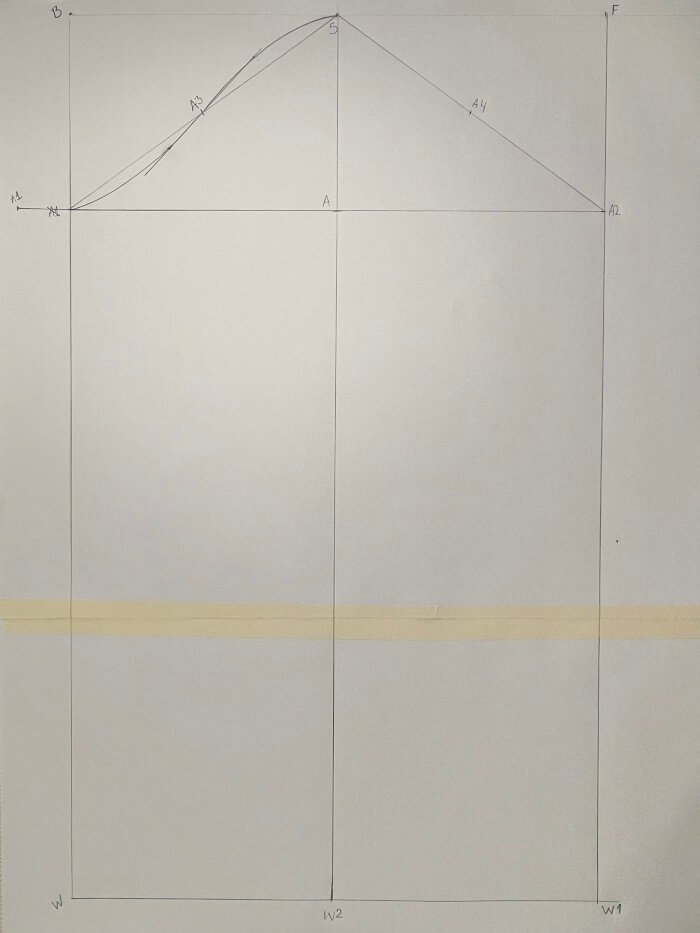

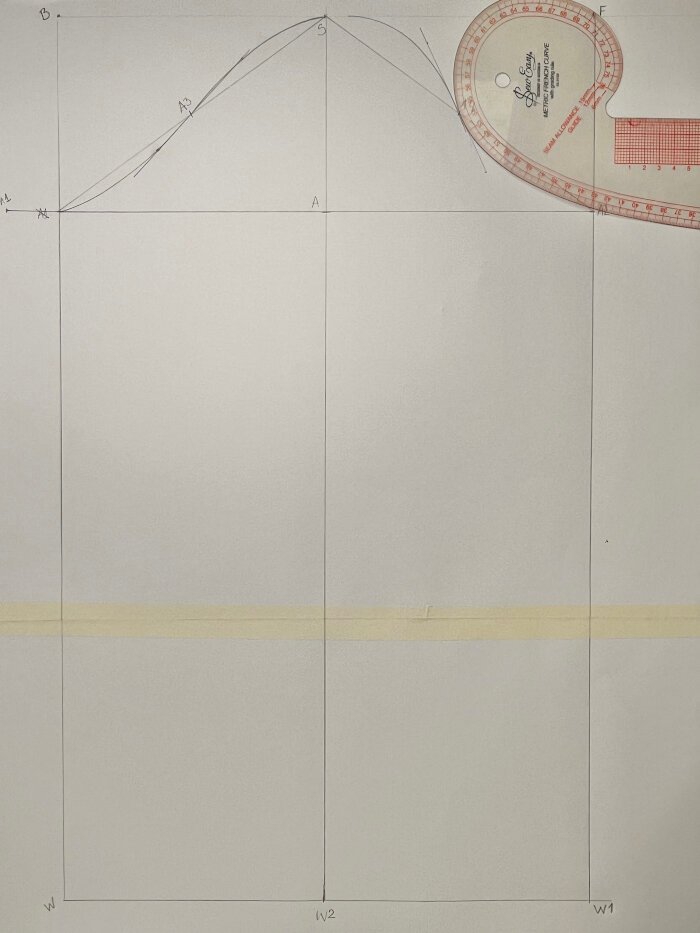

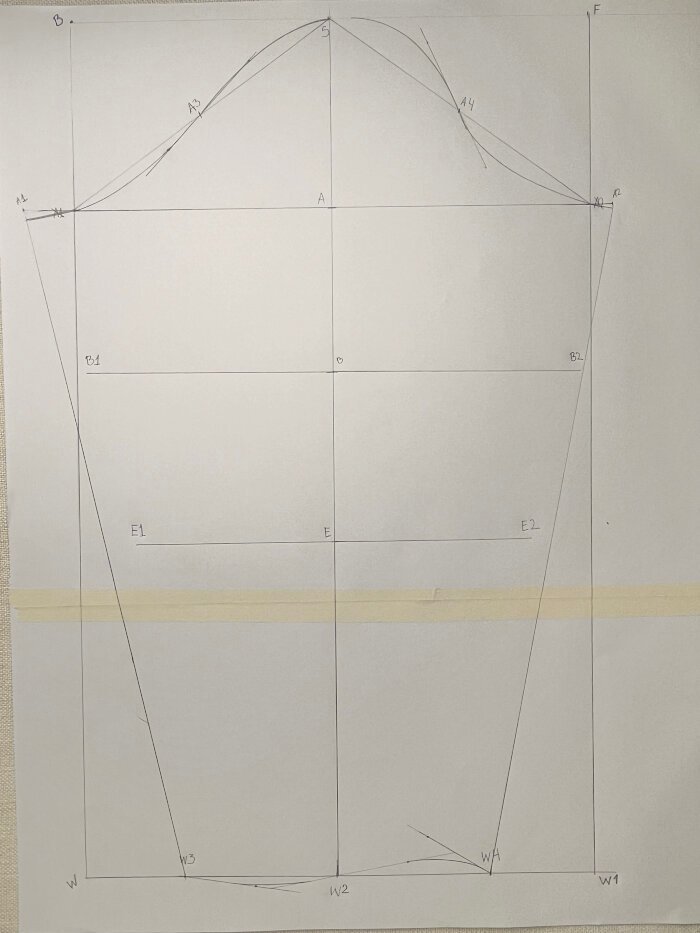

Around 1 cm from the top and 5 cm from the left side of your paper, mark point B. You will need to draw a rectangle from this point to the right and down. The rectangle has to be your your bicep circumference plus 1 cm ease wide and the upper arm hight. My measurements are 35 cm for bicep with the wearing ease it gives me 36 cm for width, and my upper arm’s length is 60 cm.

Mark top right point as F for front, bottom left as W and bottom right as W1. To clarify, the left side will be the back of the sleeve, the right side will be your front of the sleeve. The top horizontal line is the highest point of the pattern on which the sleeve connects to the shoulder. The bottom horizontal line is the wrist.

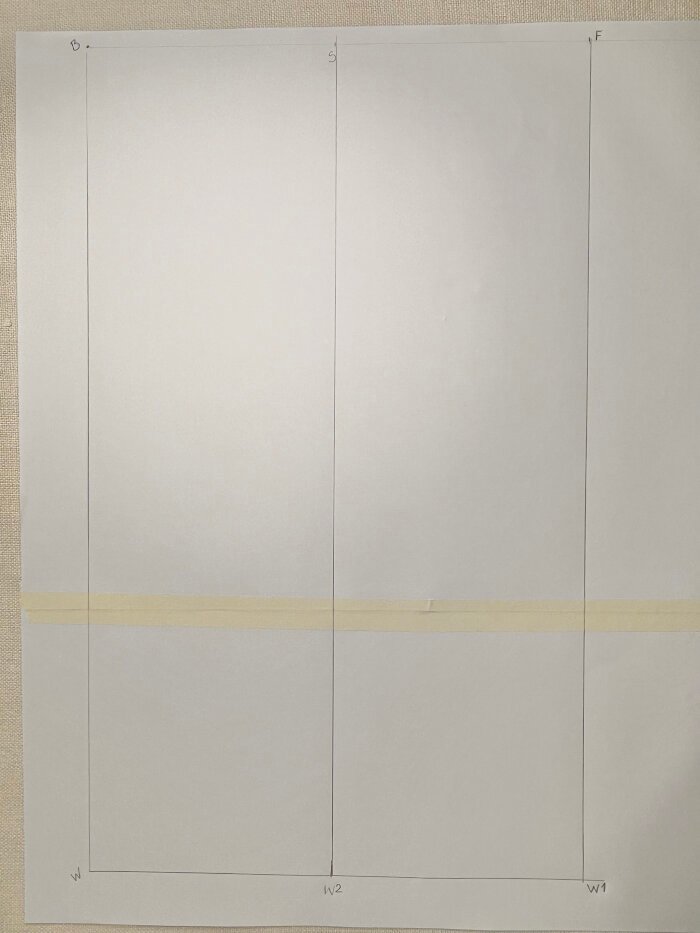

Half way across the block on BF line, mark point S. This will be your shoulder point. Square down to W2 on wrist (alternatively, mark a middle point on W-W2, the same as point S, and connect S and W2 with a straight line).

Step 2 – Draft sleeve crown

Sleeve crown height

Sleeve crown height is one of the most important parts of how to draft a sleeve pattern.

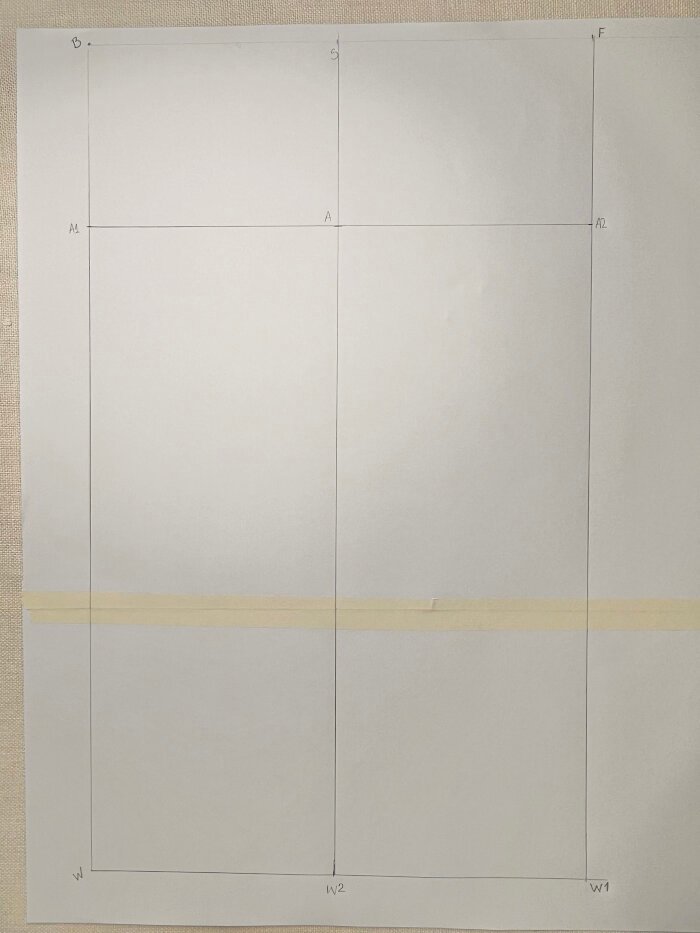

Along the line W2 to S, mark a point that is your lower arm length measured from wrist. Mark this point as A. Then square to left to connect with line BW (points A1) and to the right to connect with F-W1 (point A2). The hight of the sleeve crown is the distance from S to A.

Sleeve armhole curve on the back of sleeve pattern block

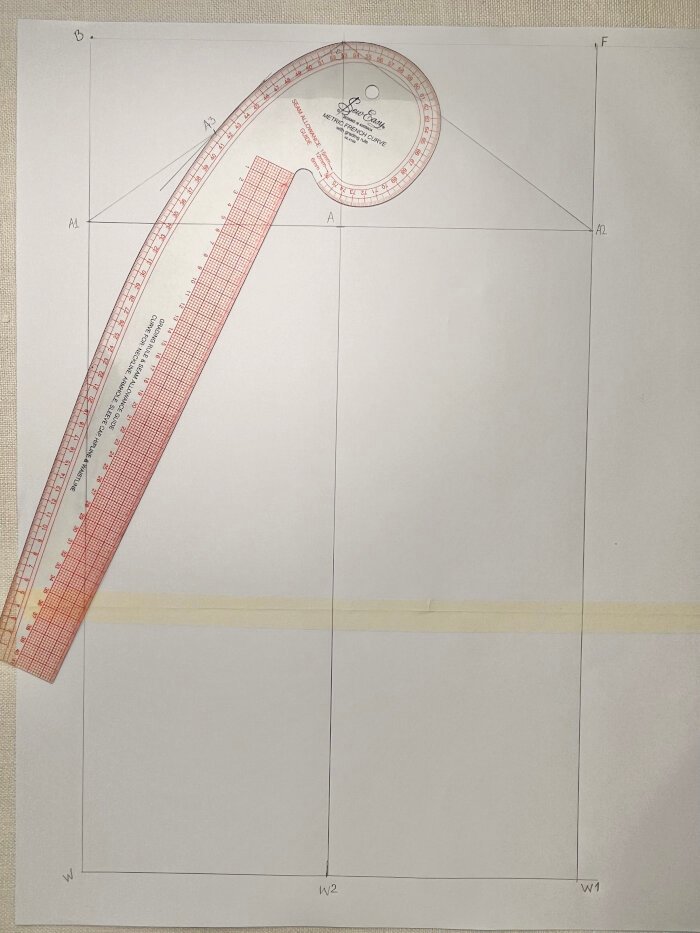

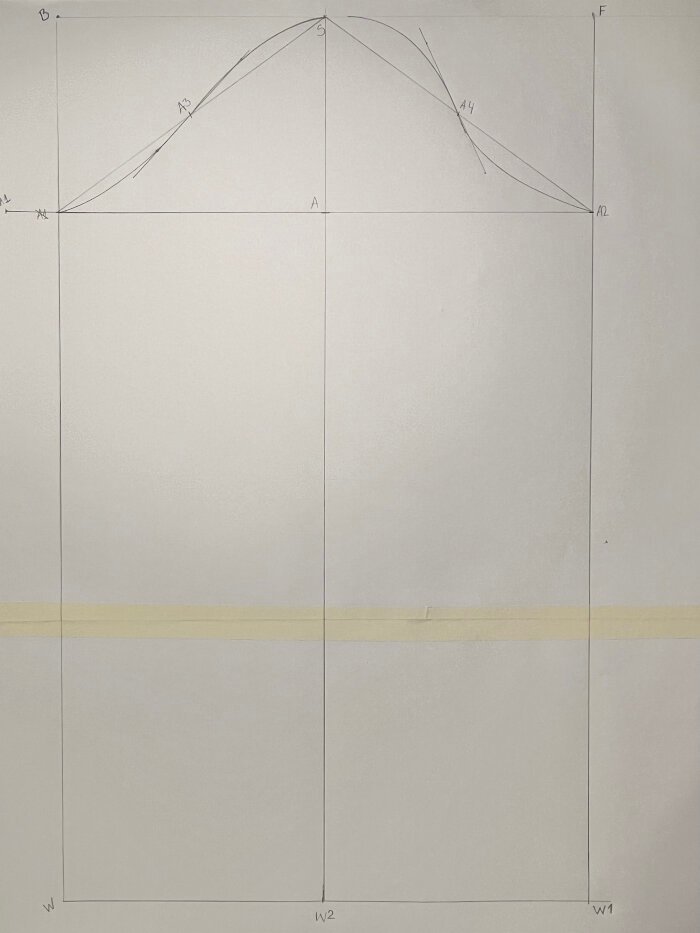

Next, connect point S with A1 and A2 with straight lines.

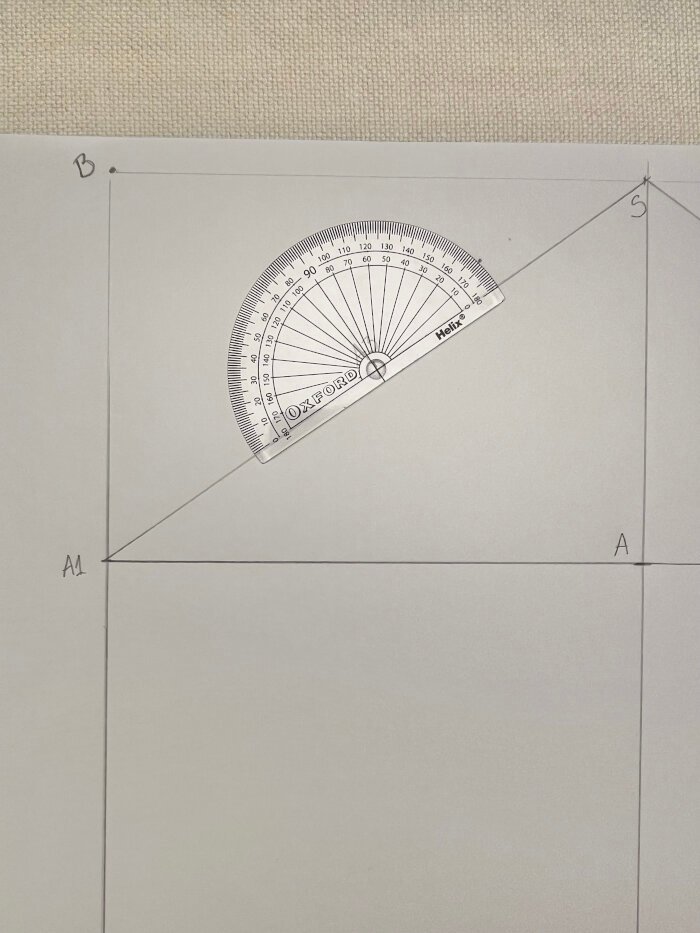

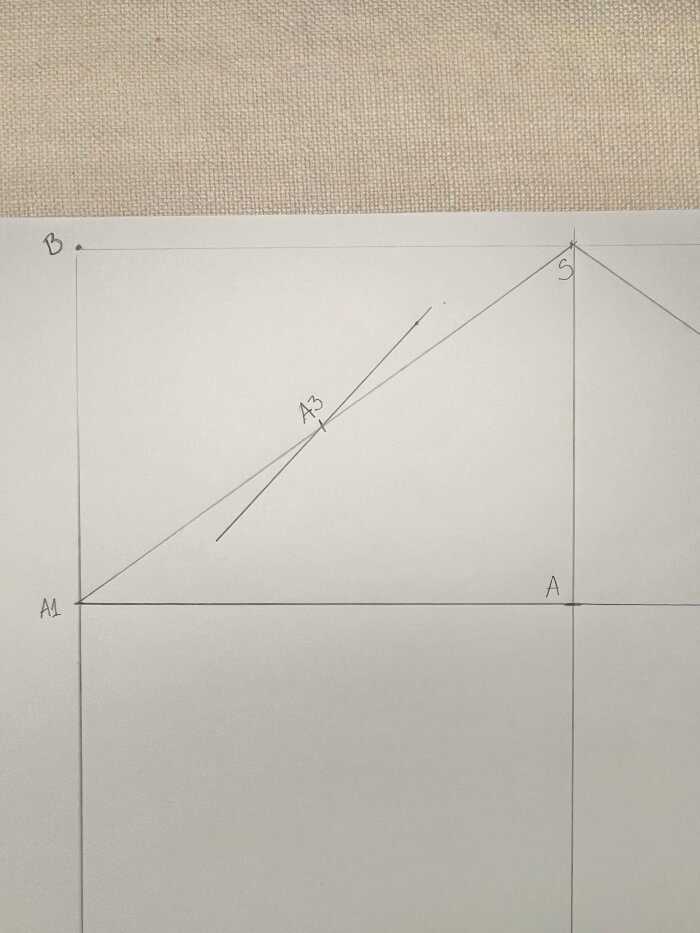

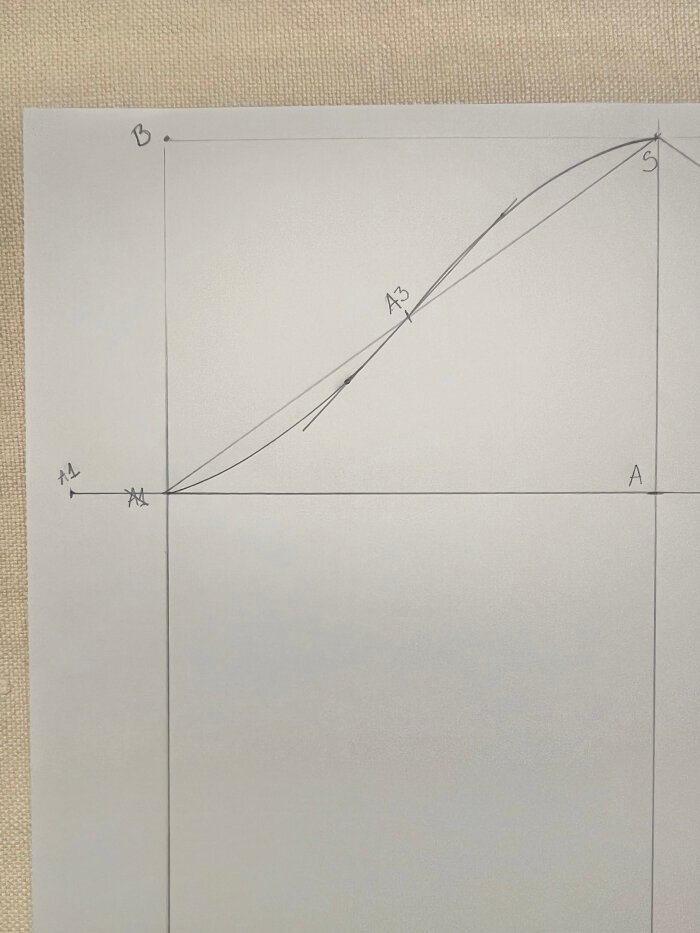

Mark a point A3 that is halfway between S and A1.

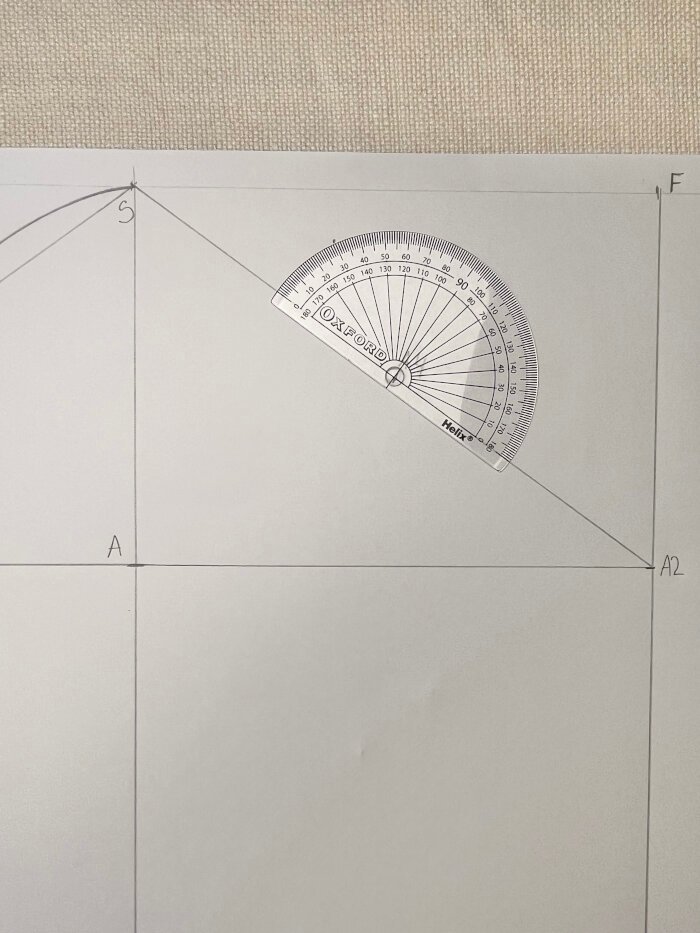

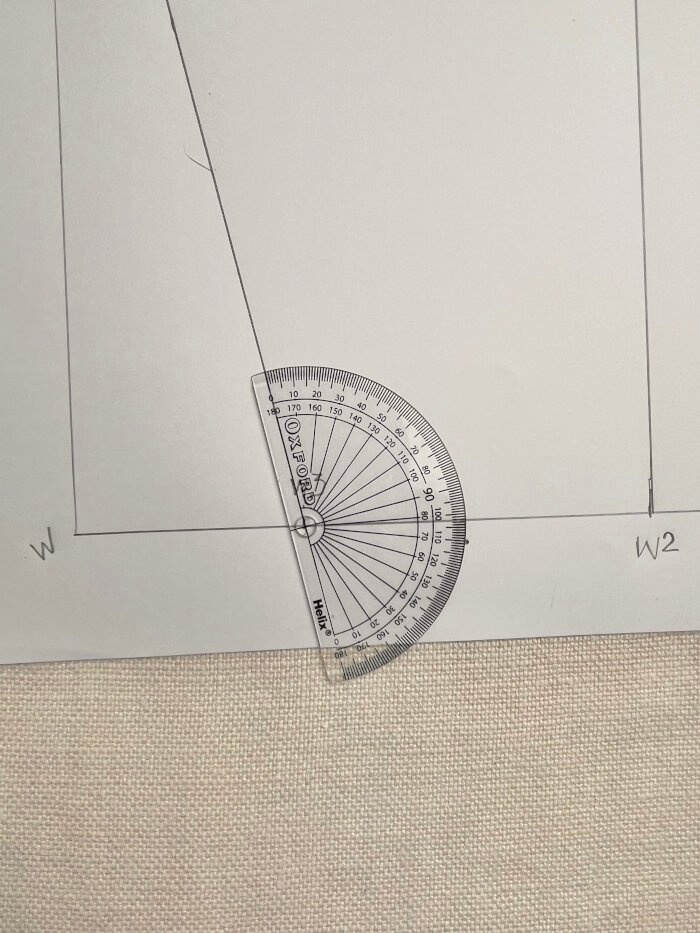

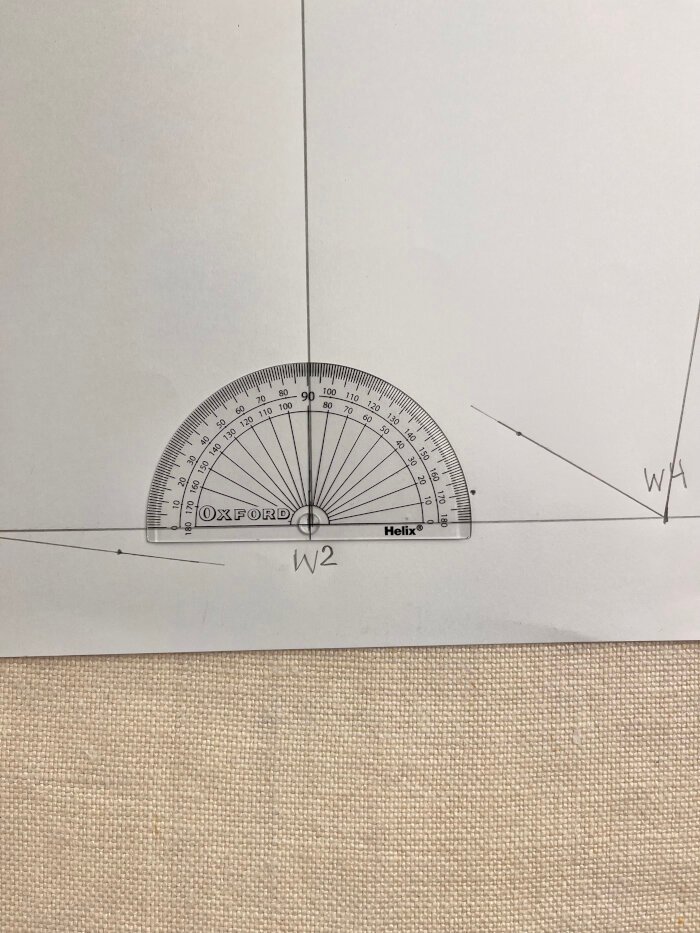

With a protractor, mark a 12 degree angle point with A3 as a vertex, above the S-A1 line (I have tried to explained how to use protractor on the post on how to draft basic bodice block, when drafting the shoulder angles in Step 4).

Then, connect A3 with the 12 degree point with a straight line, extending the line some 5 cm below and above line S-A1.

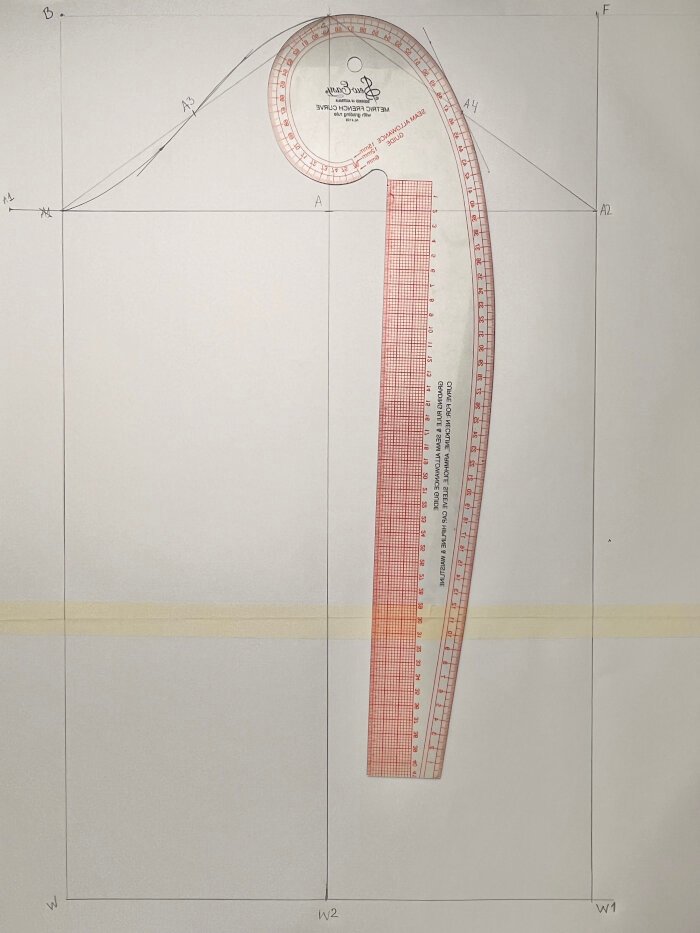

Next, with a French curve, draw a curved line from S to A1 through A3, going through the 12 degree line as shown. Make sure the curve neear S does not go above line B-F, and connects with S at a straight angle.

Measure the back curve with a tape measure on its side (see above where you measured the armscye length on the bodice block). If it is shorter than armscye measurement on the bodice back piece, extend the line A1 – A to left by the required amount. If it is larger than back arsmscye on back bodice, redraw the curve with smaller deviation (curve) from the S to A3 line. In my case ,the curve is 3.5cm too short so I extended it to left by this amount and named the end point as A1 (and removed the previous A1 point not to confuse myself).

Sleeve armhole curve on the back of sleeve pattern block

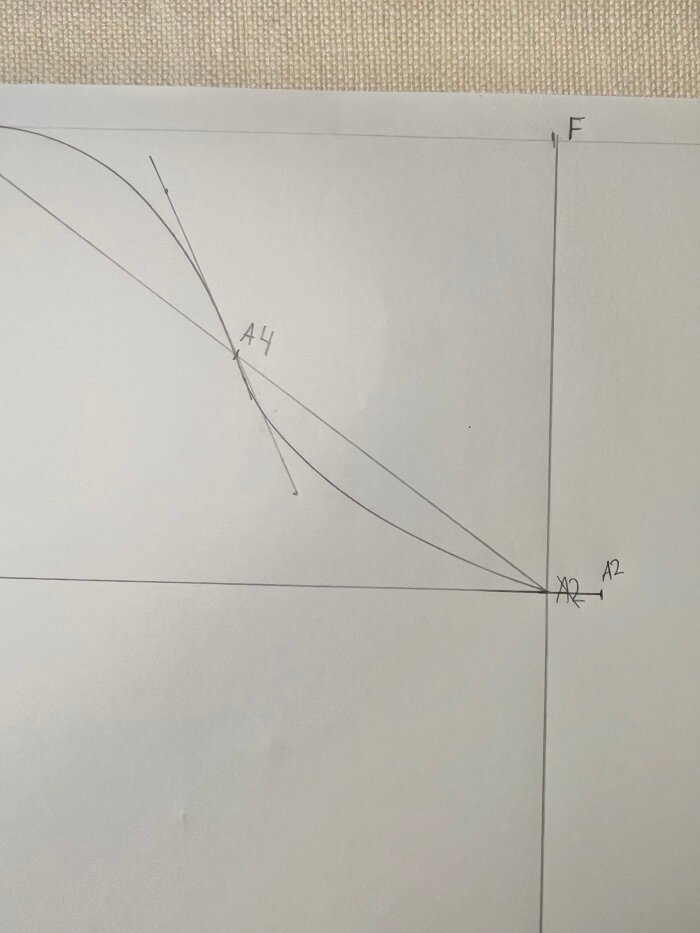

Mark point A4, halfway between S and A2.

With a protractor, mark a 30 degree angle point with A4 as a vertex, above the S-A2 line. Connect A4 with the 30 degree pot, extending the line above and below S-A2 line.

Draw a curve from S to A2 through A4, going through the 30 degree line. The lower curve should be around 2.5cm deep while the upper curve around 1.5cm deep.

Measure the front curve. If it is shorter than armscye on the bodice, extend A – A2 to right by the required length. If the curve length is larger than back arsmscye on back bodice, redraw the curve with smaller deviations from the S to A2 line. This ensures the custom sleeve pattern matches your bodice block.

In my case ,the curve is 1.5cm too short so I extended it to right by this amount, and moved the A2 to the new end point.

Step 3 – Mark bicep, elbow and wrist measurements on the sleeve block

To ensure that the final pattern fits over the bicep, elbow and wrist, you need to mark the measurements of these on the sleeve pattern. While the bicep and elbow measurement will not necessary make it on the pattern outlines, they will guide you and give you a reference point when completing the block and when making adjusted sewing patterns for garments. These checkpoints will also help you maintain accuracy in your sleeve drafting method.

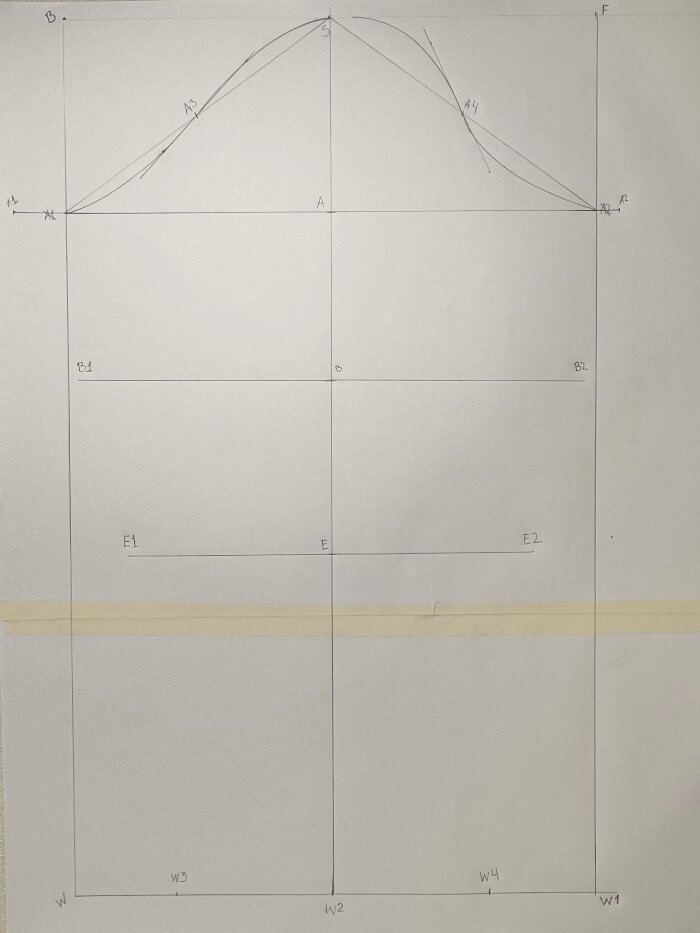

Bicep

From W, measure the wrist to bicep measurement on W-S line. Mark the point on W-S line as B. Square to the left half width of bicep circumference. Mark this point as B1. Then square to the right from B another half width of the bicep measurement; mark the end point as B2.

Elbow

Repeat the same process for elbow measurements. Measure up elbow location from wrist (point E), and square to left and right the half width of the elbow circumference, to points E1 and E2.

Wrist

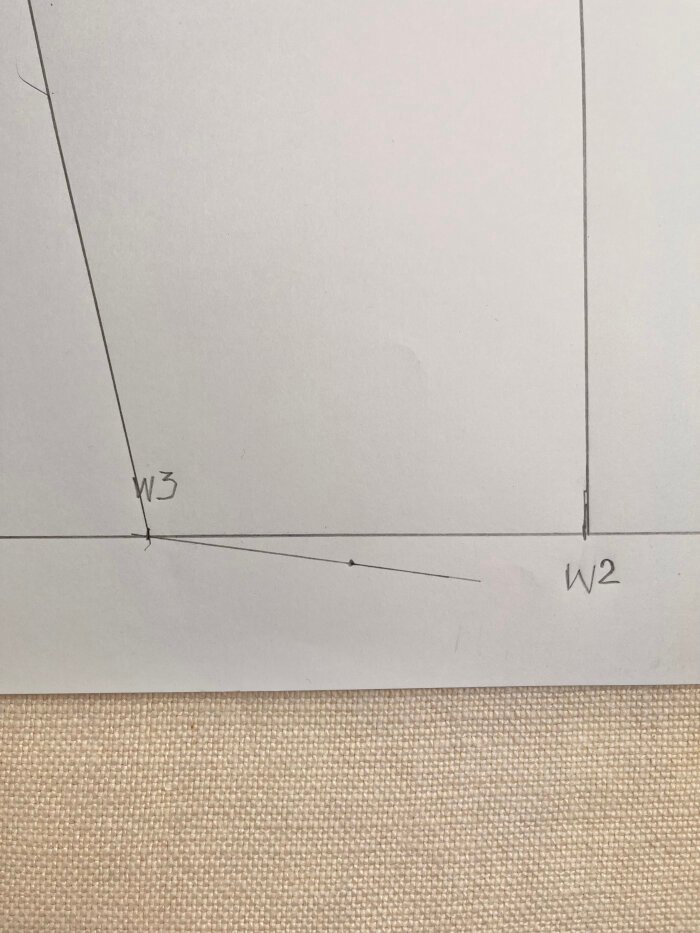

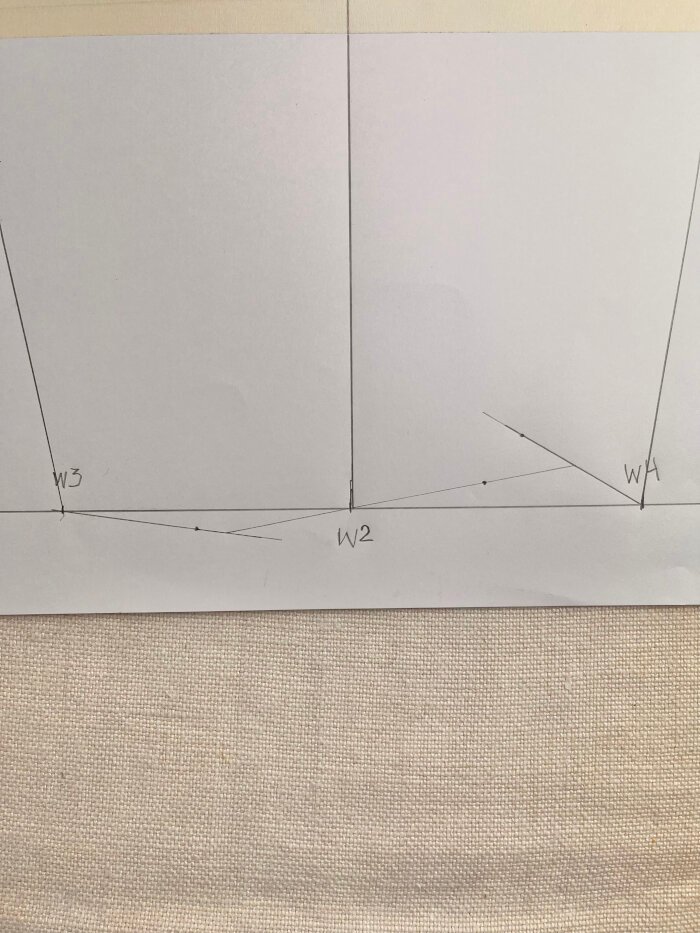

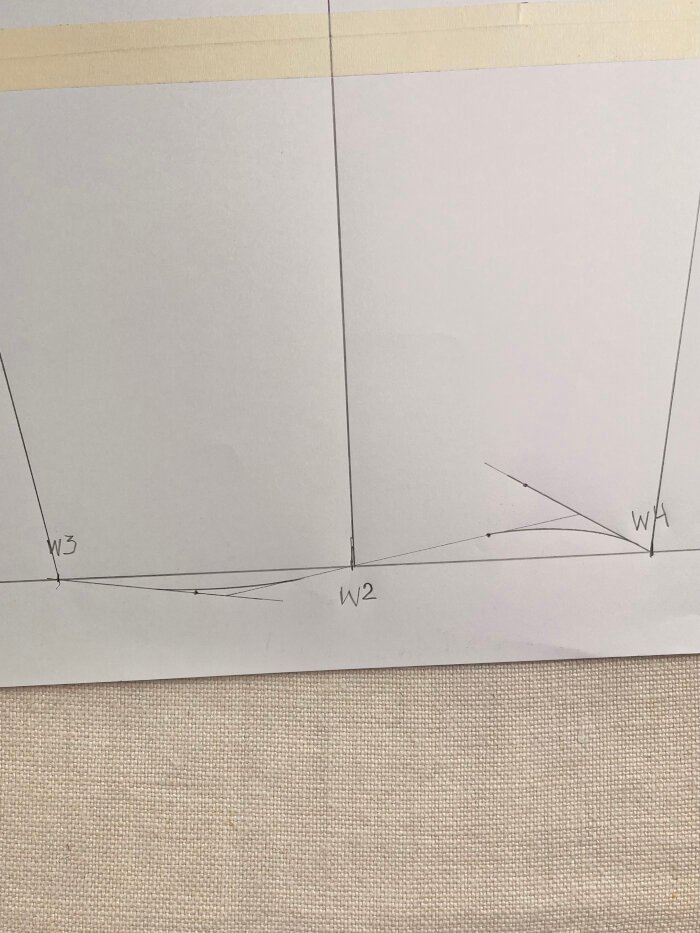

From point W2, measure half width of the wrist circumference. Mark the point as W3. Measure the same distance to the right, to point W4.

Step 4 – Draft Sleeve block ’s side seams

The fun bit is now to connect the armscye to waistline to form a basic sleeve block. This step shapes the side seams of your basic sleeve block and smooths the transition from the sleeve crown to the wrist.

Connect the new A1 point to W3 and A2 to W4 with straight lines.

If any of the points at Bicep or Elbow lines are outside of the sleeve pattern, redraw the side seems via those points that are outside the pattern. The wrist allowance would then be larger now to accommodate the larger bicep or elbow.

Ensure the line makes square at points A1 and A2. For that you may need to drop the armscye curve to connect with side seam, as shown.

Check the both side seams lines are the same length. If they are not, extend the back seam to match the length of the front seam by lowering W3 or W4 (whichever is shorter).

Step 5 – Draft a wrist line on the sleeve block

As the sleeve block drafts stands currently, if you tried to use it to make a sleeve, there would be a weird connection on the wrist line. For the transition from one side seam to other to be seamless, the angles at points W3 and W4 must make a full 180 degrees. Currently they both are wide angles of around 100 degrees each.

While you can make this correction when you are drafting a fashion pattern, I like to have my basic sleeve block usable as drafted.

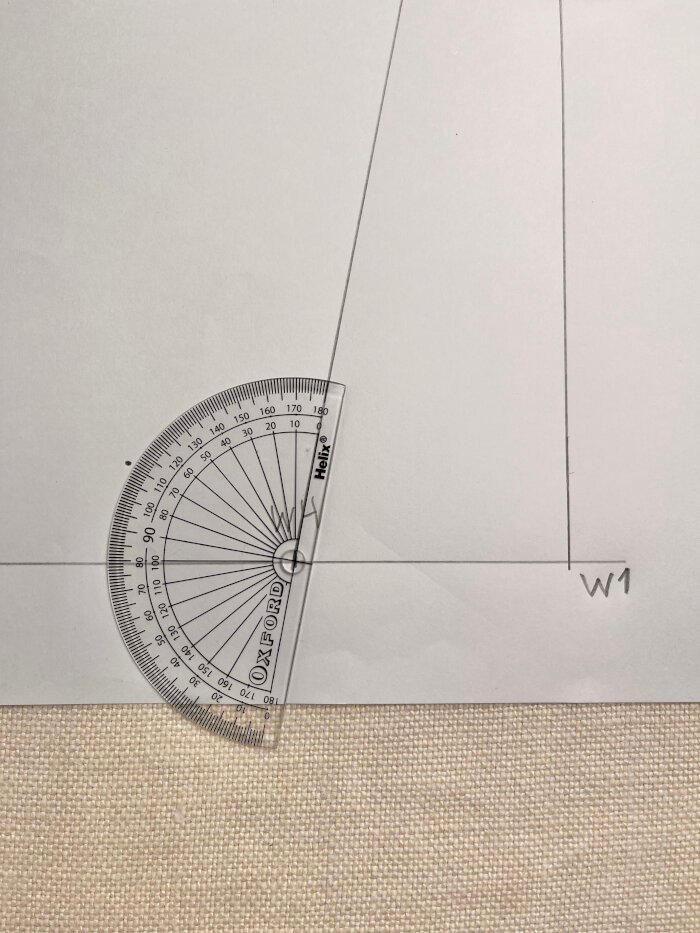

Draw a 110 degree line from A1-W3 line to drop the back sleeve block at the wrist. To do that place the protractor centre at W3 for a vertex and line W-A1 as a star that goes through 0 degrees. Find 110 degrees on the protractor and mark a dot. Then connect points W and the dot for 110 degrees with a straight line, slightly extending beyond the dot.

Then, you will need to raise point W4, to form 70 degree angle. Place the protractor centre at W4 for a vertex and line W1-A2 as a star that goes through 0 degrees. Find 70 degrees on the protractor and mark a dot. Then connect points W4 and the dot for 70 degrees with a straight line, slightly extending beyond the dot.

To make the lines that go opposite directions to meet, we need to curve them back at the centre of the wrist. To do that, draw a 10 degree line at point W2 by placing the centre of the protractor on W2, with 0 and 180 degree starts aligned with the waistline. Find a 10 degree point on the protractor. Then connect the dot with W2 and extend to meet the 110 degree and 70 degree lines as shown.

The last thing to do to finish drafting the sleeve block is to to make the wrist line curved in a smooth line rather than jagged line as it is now. Using the French curve, redraw the wrist line on the sleeve block, ensuring you do not change the angles at W3 and W4.

This refinement gives you a clean, reusable sleeve pattern drafting template.

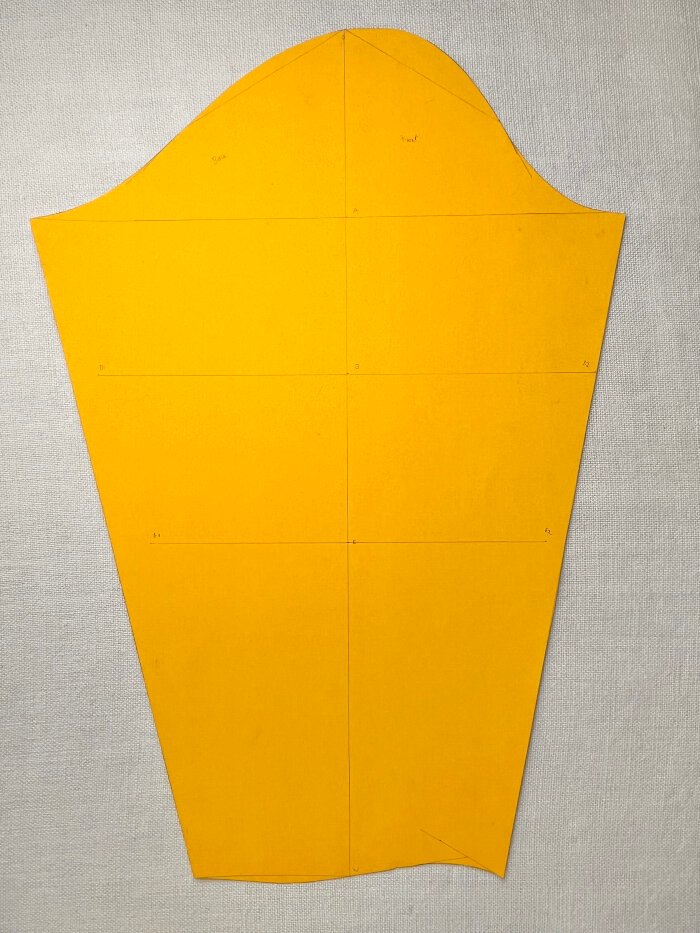

Test the sleeve block pattern

Now that you have completed all the steps of sleeve pattern drafting, you ned to test the basic sleeve block by cutting it out on some cotton canvas and stitching up. Testing your basic sleeve block in fabric helps confirm that the sleeve crown, armscye length and side seams all behave correctly.

Once you are happy with the sleeve pattern, trace it on a sturdier material, such as cardboard. It will give you a reusable block for further modifications.

To reuse the same sleeve pattern on a different bodice block, measure the armscye length at the front and back of the new bodice pattern, ensuring that you have discounted the seam allowances. Compare the measurements with the measurement on the sleeve block and adjust the A1 and A2 by moving them in or outside of your sleeve block by the difference. If you need to reduce the distance by A1 and A2, check that your biceps and elbows still fit in the sleeve. If they do not, you will need to drop crown height instead by the difference in armscye measurement, and redraw the curves.

Conclusion

Thank you for following this sleeve pattern drafting tutorial.

If you enjoyed this tutorial, you may like to read my blog post on how to create a close fitting bodice block – a perfect companion to this basic sleeve block guide.

If you prefer a video version of this tutorial, see my Youtube video where I go through the exact steps.