I spent too much time and resources this summer, trying to find shoe liner socks that would be made of natural fibres and would fit me. There were a bunch that I ordered from online shop just to find that they are way too small. Fortunately I have an offspring that was excited that she got all the lacy pretties for herself and has been wearing them all the time. So there was no reason to return them.

The offers on High street stores did not warrant further explorations and I did not have that much time to browse further with the recent changes to my family dynamics.

I do love wearing ballerina type shoes that ar easy to slip on and take off, especially while heavily pregnant of carrying the bundle of joy tied to the chest. Thus, the shoe liner socks are significant part of my everyday attire, even if the whole point of them to be invisible.

With several setbacks to refresh the shoe liner socks that I already own, I decided to attempt to draft and sew them myself. After all, how hard can they be for an experienced seamstress like me!

I have been mulling round the options and constructions and finally settled on the method that I am sharing with you on this post. Hopefully you will find it easy to follow and fir for the purpose.

Without further ado, here we go!

Outline of the instructions

I will start by listing the materials required, then explain how to take the measurements and draft the pattern, follwed by the detailed instructions to stitch together the first pair of hand made shoe liner socks in your shoe draw.

Materials required to make shoe liner socks

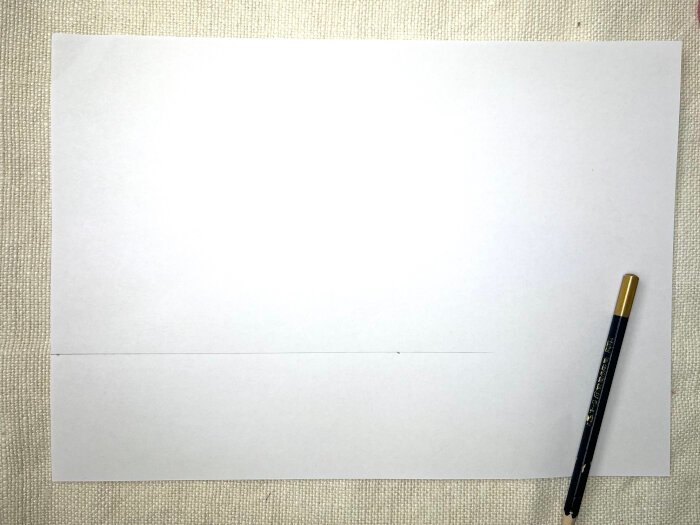

- A4 sized paper

- Pencil or pen

- Four way sretch cotton jersey / lycra

- Foldover elastic

- Scissors or rotary cutter

- Matching thread

- Sewing machine or overlocker

How to draft pattern for shoe liner socks

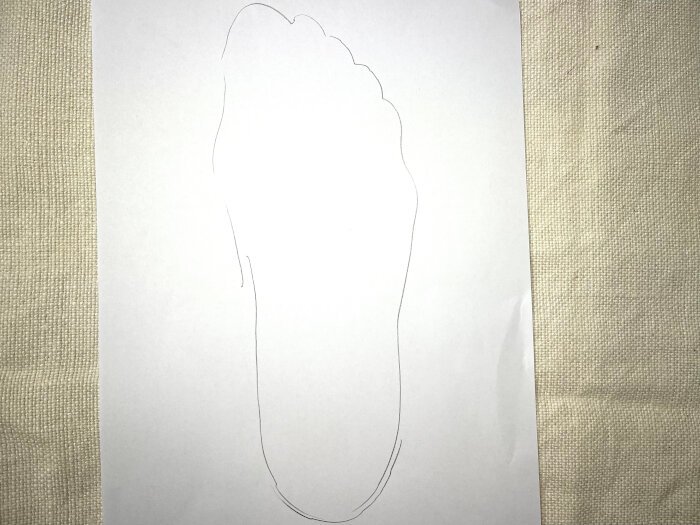

Ou will need to find a hard surface, like a hard floor, smooth chopping board, large book or cutting mat, on which to place the A4 paper and your foot. You will need to stand on the paper quite firmly, so I woukd recommend to stand up and place the paper (and the backing if using) on the floor. Then carefully trace and outline of your bare foot, keeping the pencil close to you, even slightly angling it towards the foot.

The draft does not have to be perfect but should give you the idea of the dimensions and the anatomy of your foot. Then, you need to trace a smoothed and rounded shape inside of your foor print, making the shape around 2 cm smaller than your foot. Ignore the bunions or shape of your toes, we are going to use a stretchy cotton jersey fabric that will smooth out any bumps or lumps.

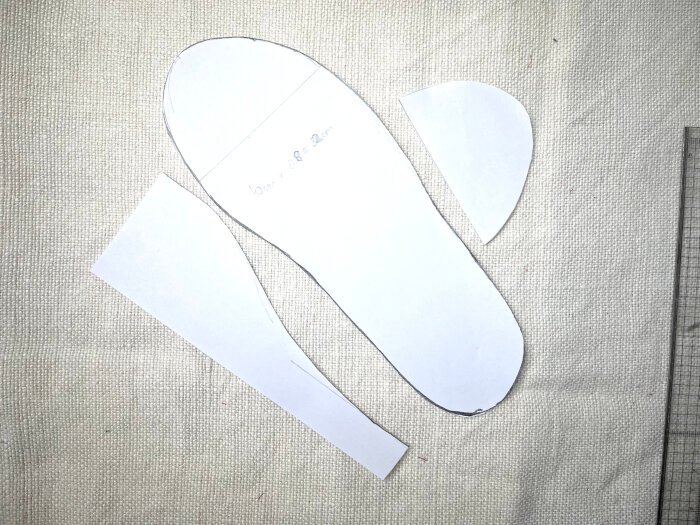

Then cut out the drafted pattern for the base of the shoe liner socks.

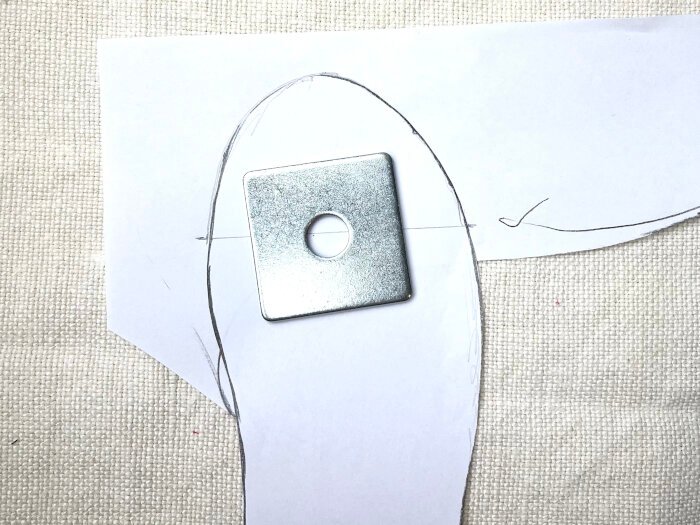

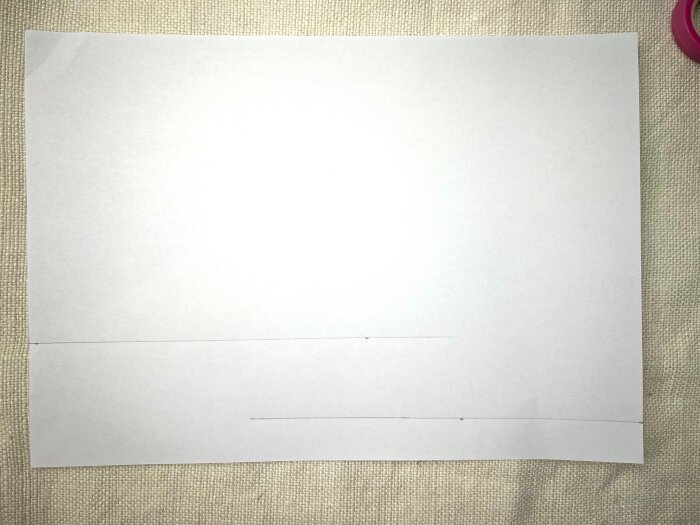

Next, measure how far form the big toe you would like the upper part of the shoe liner sock to go. It woud be helpful to wear a shoe that you would most likely to wear with your finished article to give you an idea how far the sock should cover at the front.

I chose to go for 5 cm. Mark this on your sock base pattern and connect the sides with a straight line or mark dots on the side of the pattern. Then place the base pattern on a scrap of paper left over from cutting the piece, and trace around it to the distance marked on the sides.

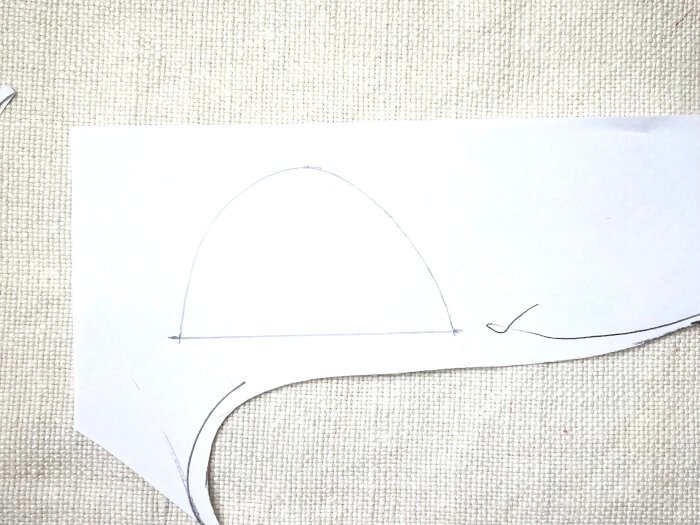

Then, remove the base pattern, connect the sides of the traced outline with a straight line and cut out the pattern. This is going to be the top of the pattern.

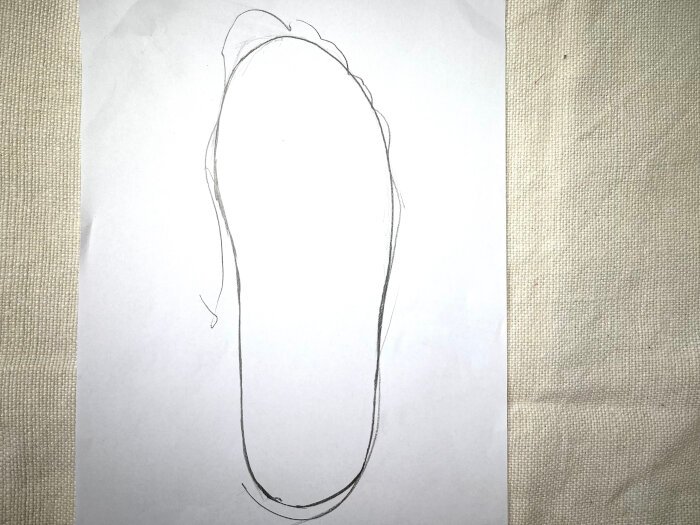

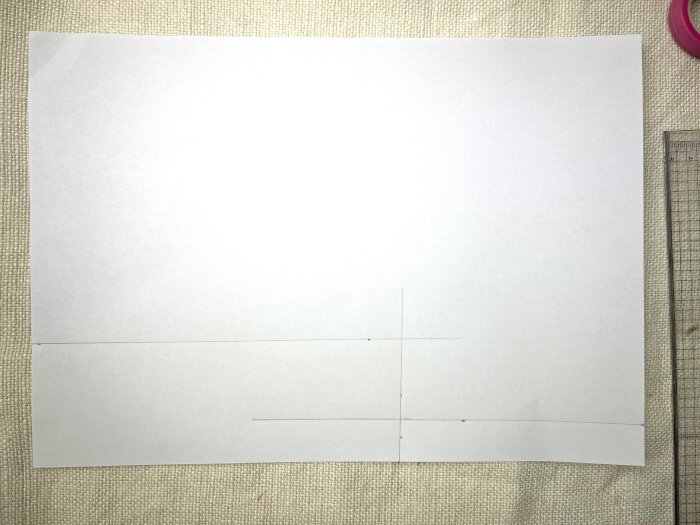

Next, measure the distance on the base pattern from the mark on one side to the other, going round the heel of the foot. Keep the tape on the side to make the measuring easier. Mutiply this measurement by 0.9. I measured that the distance between those dots are 40 cm, so the calculation gives me 36cm.

Then, either use a scrap paper that it at least 20 cm long and 7 cm tall or another A4 paper, mark a dot on the shorter side, that is 6cm high from the bottom. Square out around 10 cm.

On the other side, mark a dot that is 2 cm above the bottom of the page, and square across to the other side of the page.

Now, measure the distance from the left side that is half of the measurement you did around the heel. For me that is 18cm, half of 36 cm. Square up to meet the 2 cm and 6 cm lines that you draw from the sides.

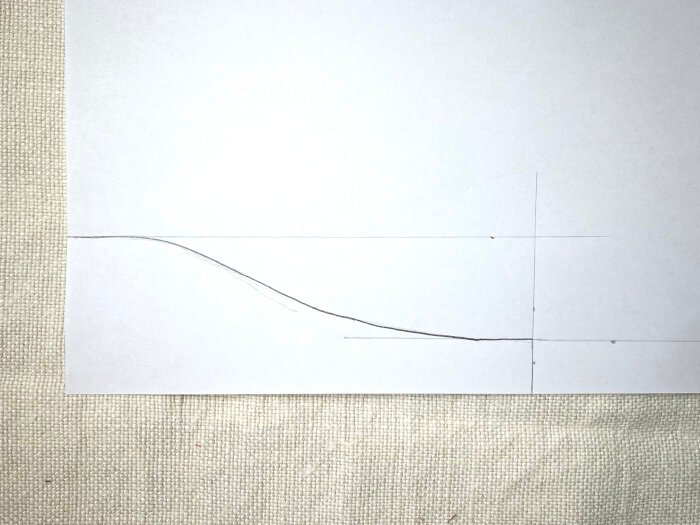

Next, connect the 6 cm line with the 2 cm line with a curve line, keeping straight angles at the left and at the 2cm lines.

Cut out the shape. This is going to be the sides of the shoe liner socks.

Cutting the fabric for shoe liner socks

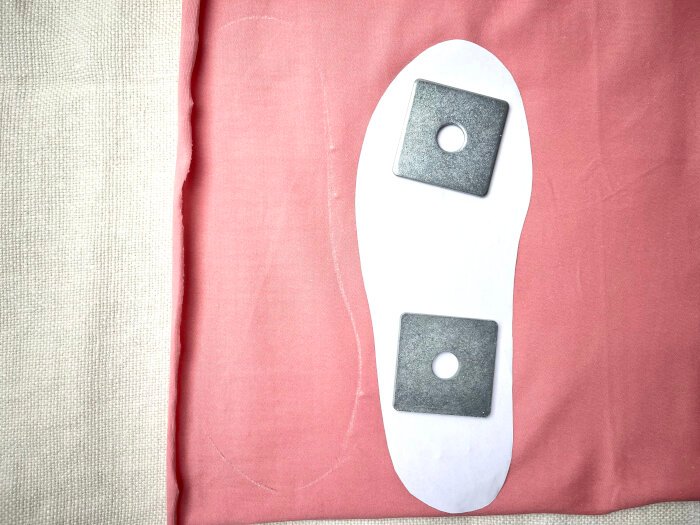

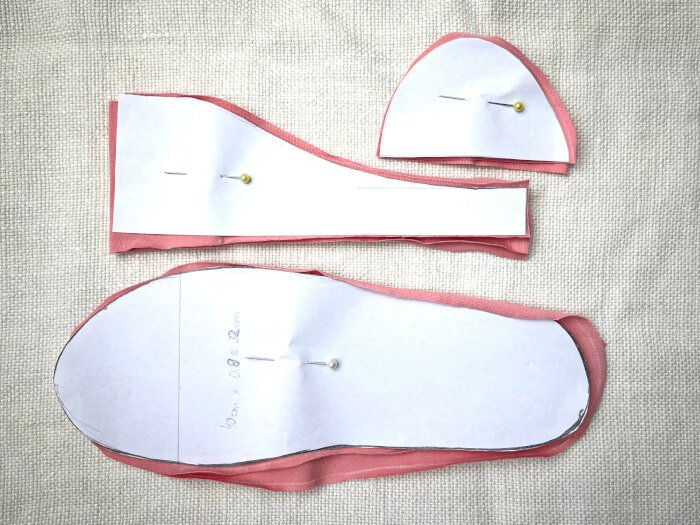

You will need to cut out two of each of the pattern pieces, with the sides cut on the fold.

Both the base of the shoe liner socks and the top will need to be cut as a mirror image. I find that in order to reduce the waste, it is best to cut the base patterns indivusually, fliping the pattern upside down and over after the first. The grain line for all the pieces are the same, they go from side to side.

You will need to cut a scant 0.5 cm seam allowance to the base pattern. So, you can either trace the outline of the base pattern and then cut with scissors, or use a rotary cutter to cut around it.

Next, trace and cut out the two mirror images of the top piece, adding scant 0.5 cm seam allowance to the curved outside line. The seam allowance is not added to the straight edge but it needs to be cut very straight to make the attaching the elastic easier.

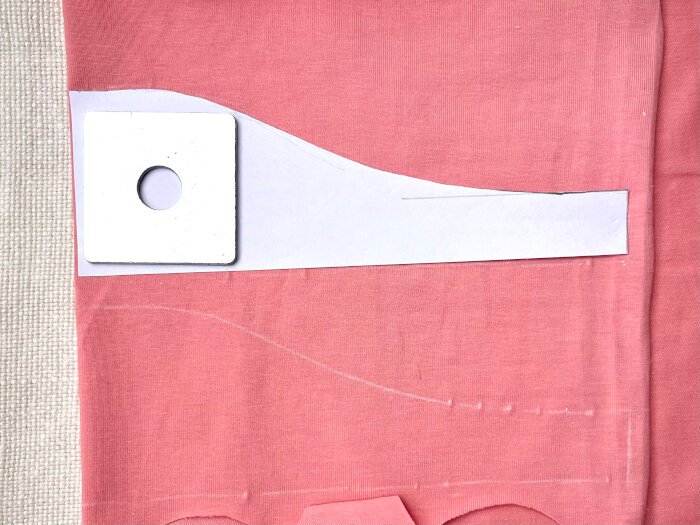

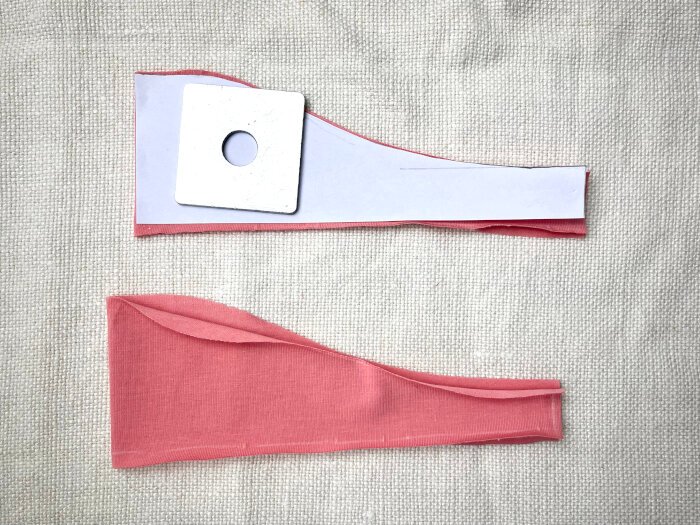

Then, fold the cotton lycra from left to right (selvedges facing the same direction)m and place the side pattern with the higher heel section on the fold. Add scant 0.5 cm seam allowance to the bottom straight edge and the right side, without any seam allowance for the curved edge.

Cut the pattern piece out, making sure that the curved edge is as smooth as possible.

Pin all the pieces with their corrsponging patterns to not to loose the tiny sections while you set up the sewing machine.

How to sew shoe liner socks

Align the narrow end of the side pieces with the top piece, with right sides together. Ensure that the curved edge of the side piece is on the inside.

Then sew the pieces together with narrow zigzag stitch. There is no need to back stitch at either end as you are going to sew elastic and attach the sole. You are going to reduce the bulky seams if you do not backsticth.

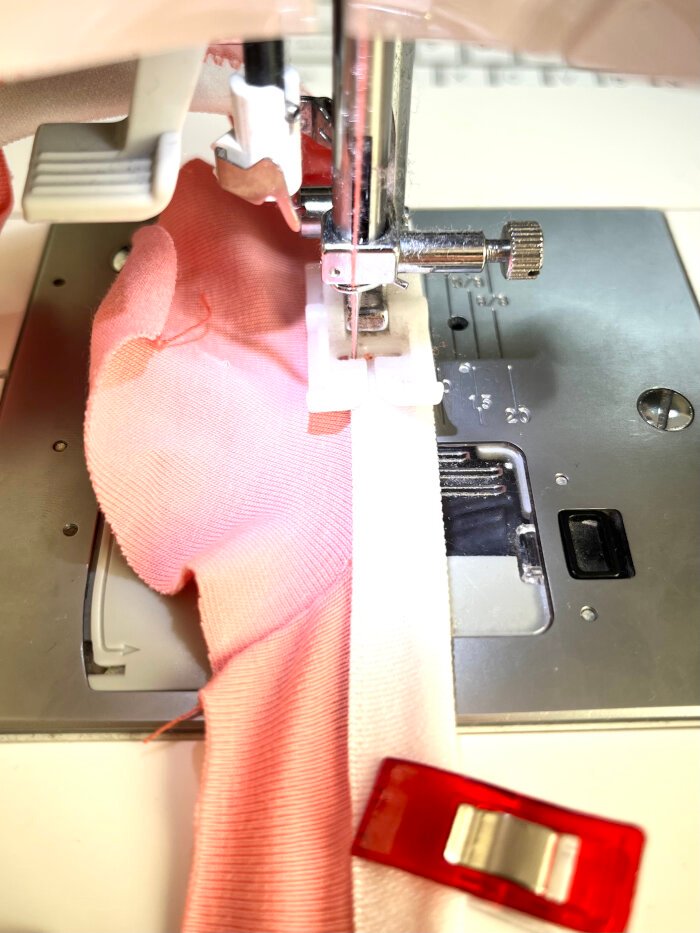

Next, we need to sew on the foldover elastic on the curved edge. Start by laying the folover elastic flat on the sewing machine, then bring the edge of the sock piece to the centre of the ekastic and foldover the other side of the elastic. My recomendation is to start sewing the elastic at the inside of the foot instead of the toes or heel to reduce the bulk in these areas.

Do not stretch the fabric or the elastic as you start sewing. Once you have stitched 1cm, while keeping the needle down, stretch the elastic to its maximum and then relax it a fraction. Continue sewing with this tension, pulling fabric at the back of the sewing machine and pulling the elastic at the front.

Continue sewing all around the curved edge, straightening the fabric before it goes under the sewing foot. This way it will be easier to attach the foldover elastic neatly.

Before you reach the beginning of the elastic, trim the foldover elastic so that it goes over the end that you have already attached and you can fold it under, to hide the raw edge.

Pin or klip the bottom / sole part to the upper part of the shoe liner sock with right sides together, keeping the toe and heel unstreatched (this will help to keep the seam straight and neat when sewing).

Sew the sole to the upper part with either narrow zigzag stitch on your sewing machine or with 3 threads on the overlocker (I prefer overlocker for this part as it cuts the seam allownce and keeps the seam neater). Strech the sides of the sock as you go, to match up with longer side seams of shoe liner sock’s sole.

Turn the sock inside out and marvel of yet another amazingly simple project that no doubt will bring you as much joy as it did for me!

Conclusions

Initially I had intended to make the shoe liner socks with clear swimwear elastic but it was not playing the ball. Every time I tried to sew with it, the sewing machine was throwing a tantrum. I have a feeling that this elastic is not not meant to be stretched while sowing.

The foldover elastic is a great alternative. I was slightly concerned that the sock might be slipping without a silicone grip but I should not have fret, it works wonderfully.

One things that I will experiment with on the next project is to make the pattern pieces for soles and the toes more symmetrical. The cut out pieces were rolling up a little and I was struggling to see which is right side and which is left side. Plus, I do not think the foot shape makes as much difference when wearing the article. I bet I will not be checking whether I have put the right sock on the right foot when I pull the shoe liner socks out of the draw.

I am also planning to eliminate the seam allowances or reduce the length of the sole and side pieces as the fabric that I used had a good stretch and would require a bigger negative ease. This might depend on the weight of the cotton jersey. The one I used had a good stretch and was around 200 GSM.

All in all, I am very happy with the result and the only thing I will buy is black and cream coloured foldover elastic to match with the colour of my shoes.