Sewing a fitted T-shirt that actually fits is difficult when you rely on commercial patterns. In this beginner-friendly guide on how to sew a fitted T-shirt for women, you’ll learn to create a custom jersey T-shirt that fits your body perfectly using a bodice and sleeve block drafted to your own measurements.

This tutorial builds directly on my previous posts on drafting a T-shirt bodice block and sleeve block for knit fabrics. Using this method, you can create a custom fitted T-shirt, comfortable everyday tops, pyjama tops, and breastfeeding-friendly styles from a single reusable knit T-shirt pattern drafted from blocks.

This women’s fitted T-shirt sewing tutorial will help you create a go-to wardrobe staple that fits smoothly at the bust, waist, and hips without fabric bunching or overstretching.

The DIY T-shirt goes well with skirts, jeans , tailored trousers, gym clothes and sweatpants. It is very versatile and can be made of cotton jersey for tighter fit or viscose jersey for a flowy and more romantic look. While I do not tend to sew with polyester fabrics, this custom T-shirt would work well with performance and athletic fabrics too for a gym or running outfits.

This makes it an ideal project if you want to sew a jersey T-shirt that actually fits your body and lifestyle.

What You Will Learn

In this step-by-step fitted T-shirt sewing tutorial, you will learn how to:

- Assemble knit garments with clean, professional finishes using jersey fabric

- Turn a basic T-shirt bodice and sleeve block into a wearable knit garment

- Adjust a neckline correctly for a neckband

- Sew a fitted jersey T-shirt for women using just 1 metre of fabric

Materials and Tools Required

To sew the DIY t-shirt, you will need these materials and tools:

- Basic T-shirt bodice and sleeve block patterns

- Paper for pattern tracing (A1 paper, taped sheets, or wrapping paper)

- Ruler

- Pencil or pen

- Tape measure

- 1 metre of cotton or viscose jersey (approx. 150 cm wide)

- Matching thread

- Fabric and paper scissors

- Ballpoint or stretch sewing machine needles

- Overlocker or sewing machine with zigzag stitch

Step 1: Preparing a Custom Fitted T-Shirt Pattern from a Bodice Block

This tutorial assumes you have already drafted a basic T-shirt bodice and sleeve block; if not, refer to my T-shirt bodice block drafting tutorial for knit fabrics before continuing.

Tracing the Bodice Block

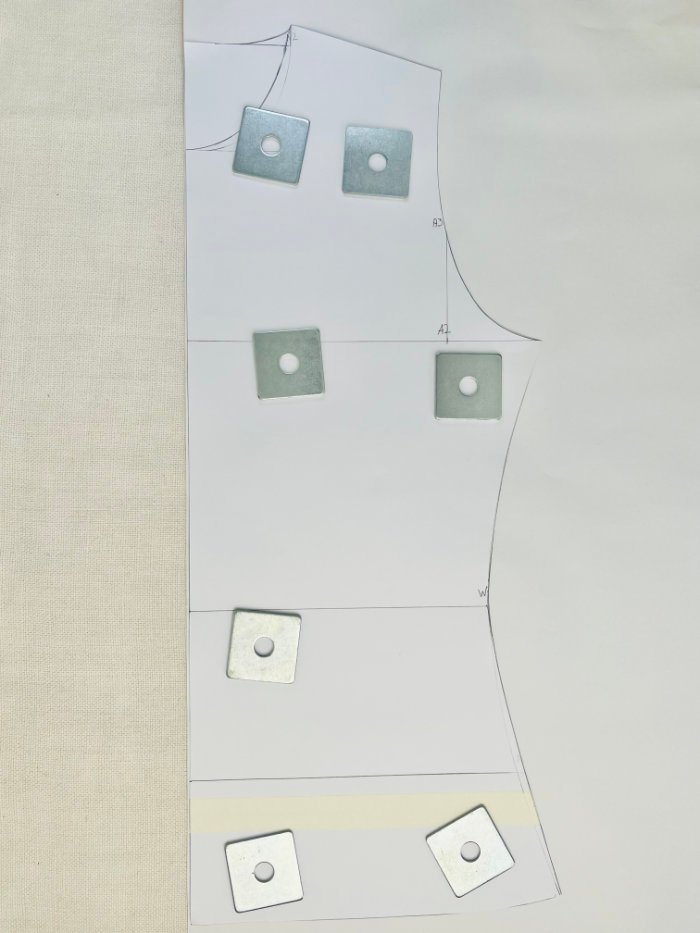

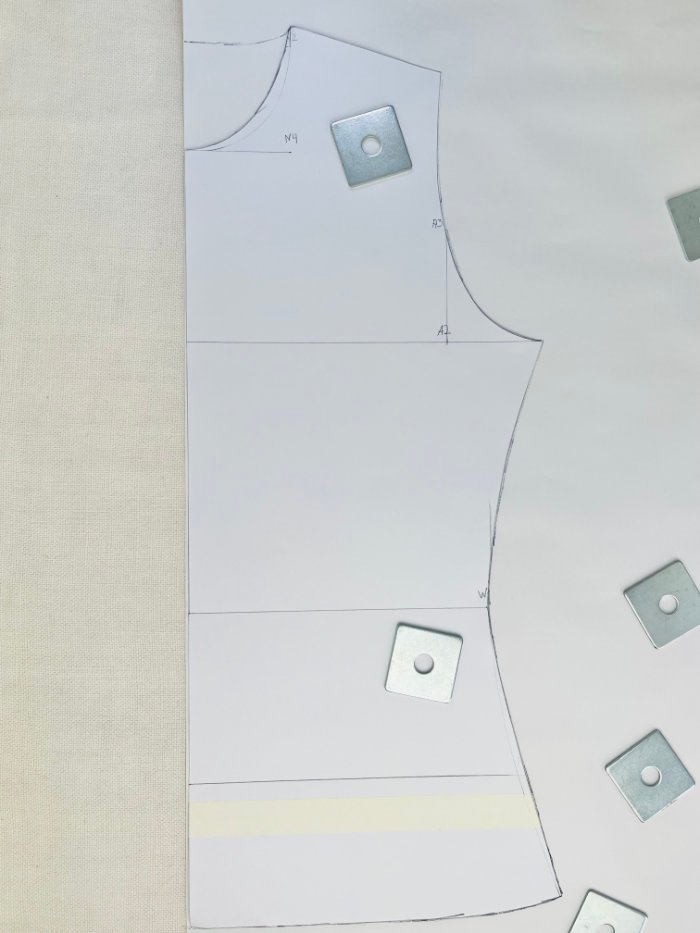

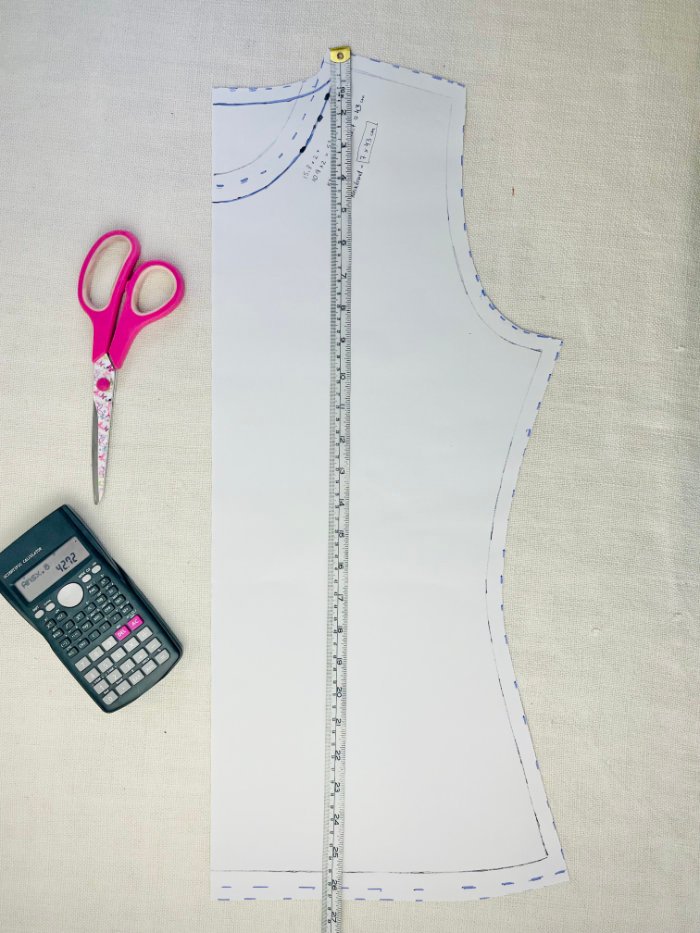

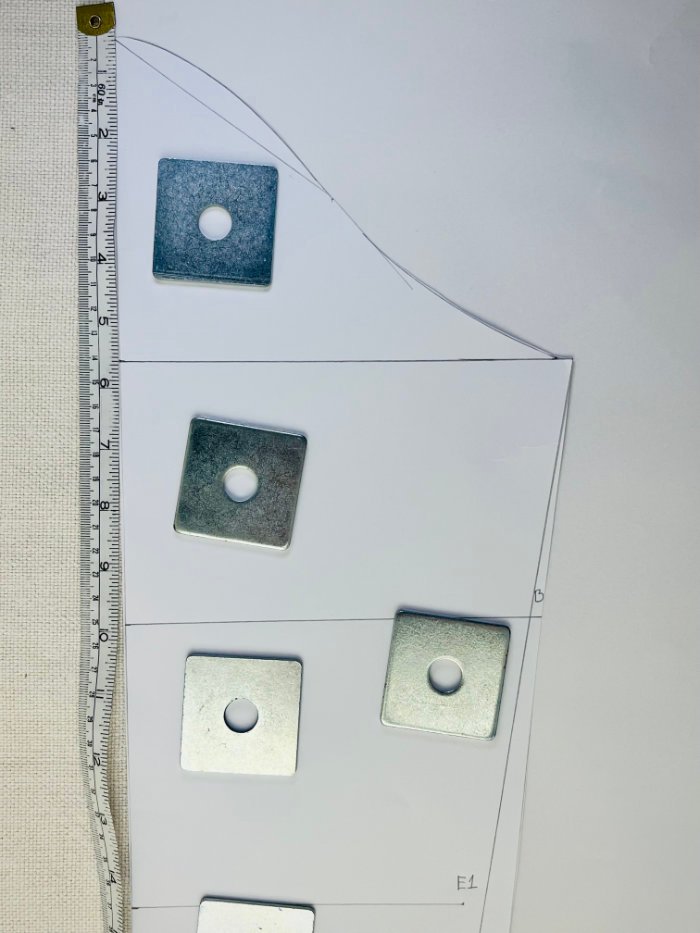

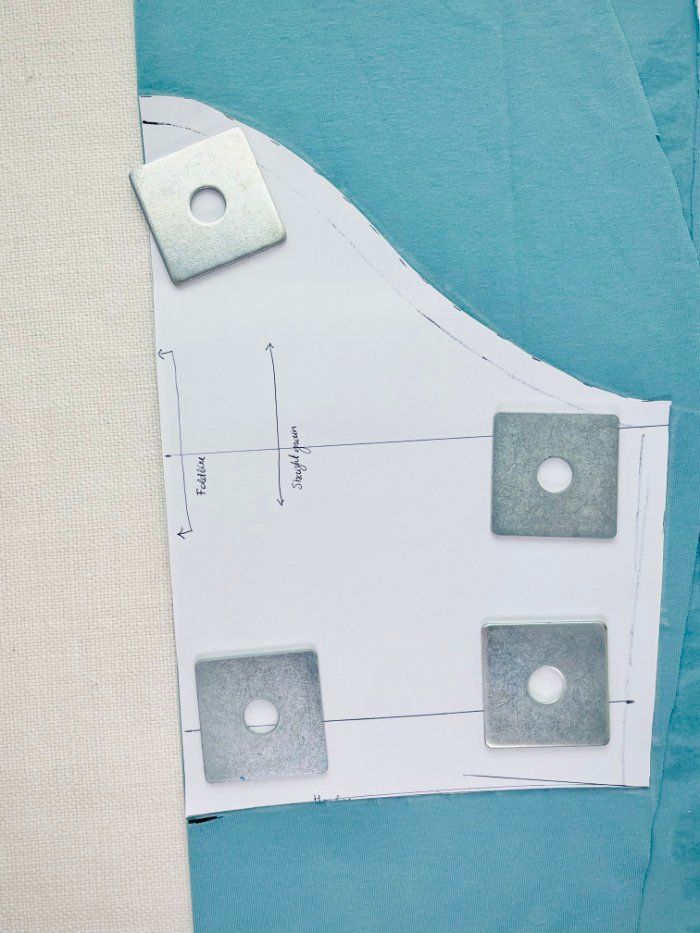

Let’s start by tracing the bodice block onto a clean sheet of paper. Place the pattern piece with the straight fold line against the straight edge of the paper. Keep a gap a the top and the bottom of the pattern that is at least 1 cm wide. Secure the paper pattern in place with paper weights or any heavier objects to keep the pattern from moving around.

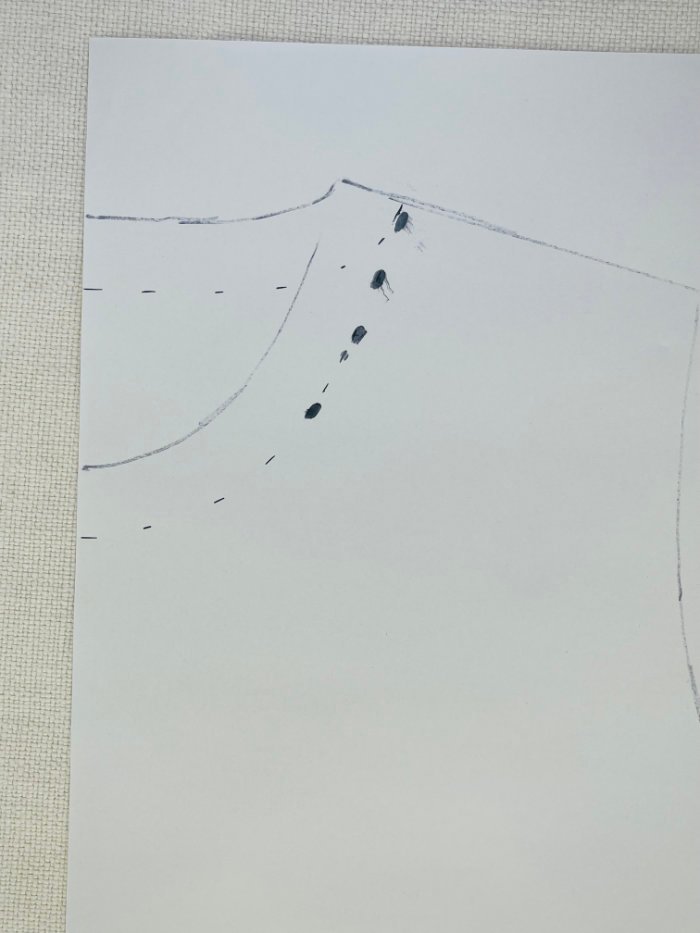

Trace around the block pattern with a pen or pencil of your choice.

You are going to trace the same pattern piece for the front and the back. Therefore, you will need to cut and fold back the front neck opening on the basic block when you are tracing the pattern on the paper.

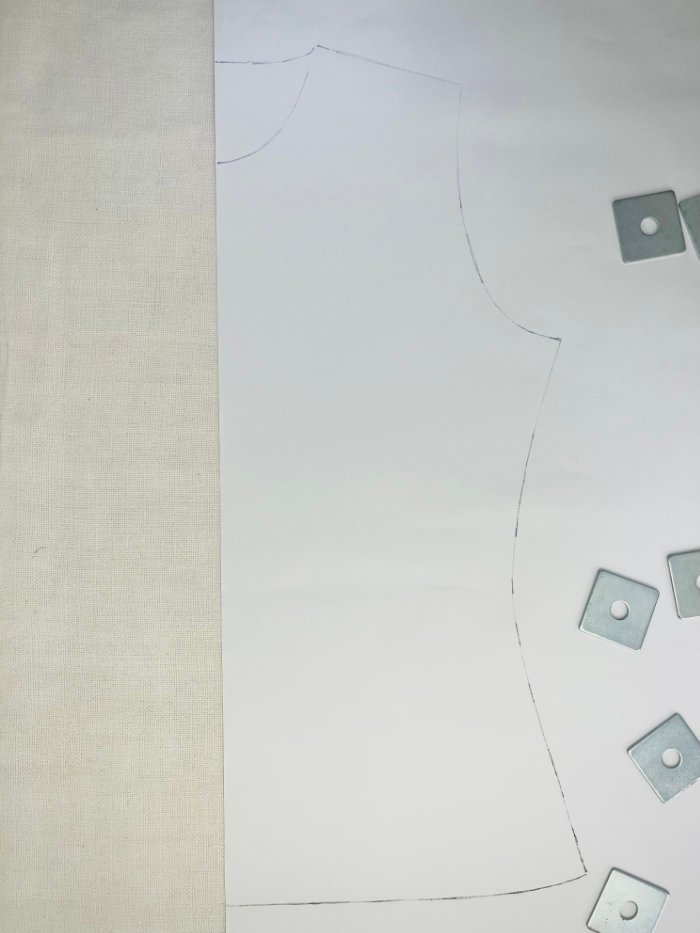

Remove the T-shirt block pattern to reveal the traced pattern.

Adjusting the Neckline for a Neckband

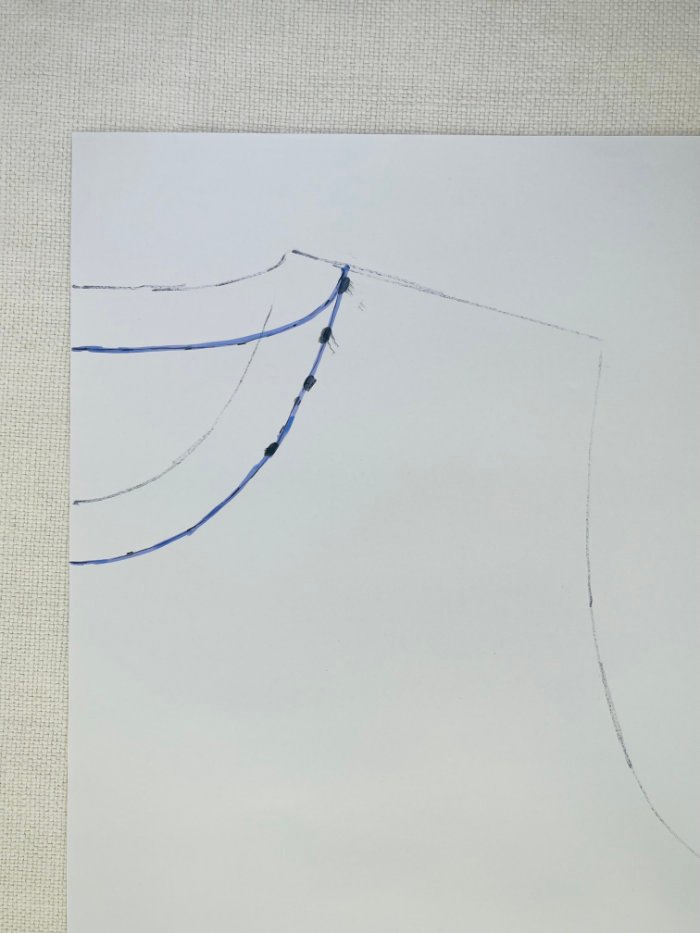

Then, increase the neck opening all around by marking dots 2 cm from the original neck width. This is needed to add a neckband later.

Connect the dots with smooth line.

Adding Seam Allowances

Next, mark 1 cm seam allowance all around the pattern, except for the hem. You need to mark 2 cm seam allowance for the hem. There is no need to connect the dots if you have marked them close enough.

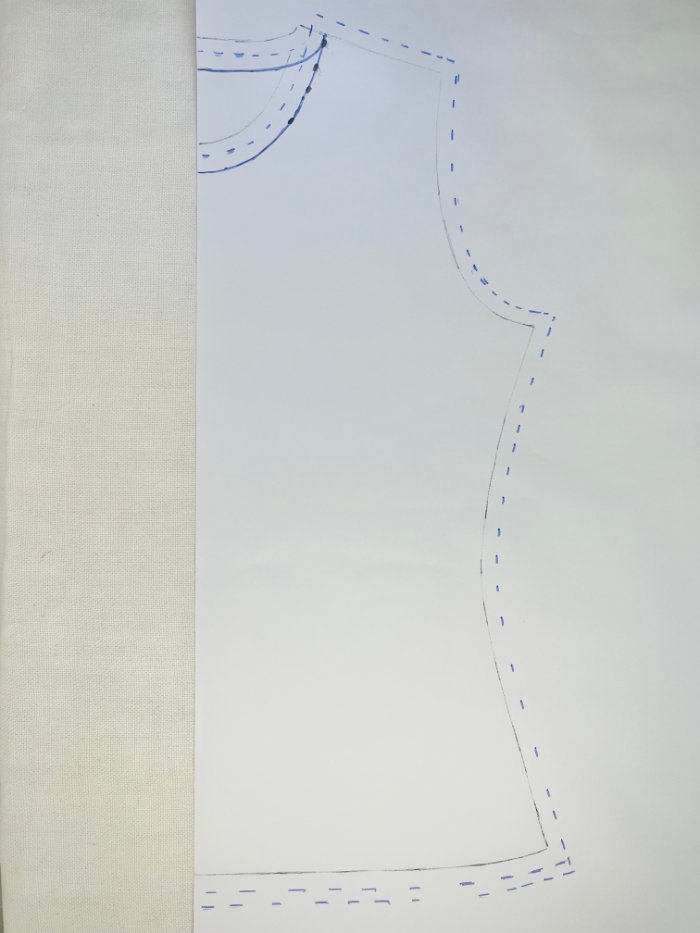

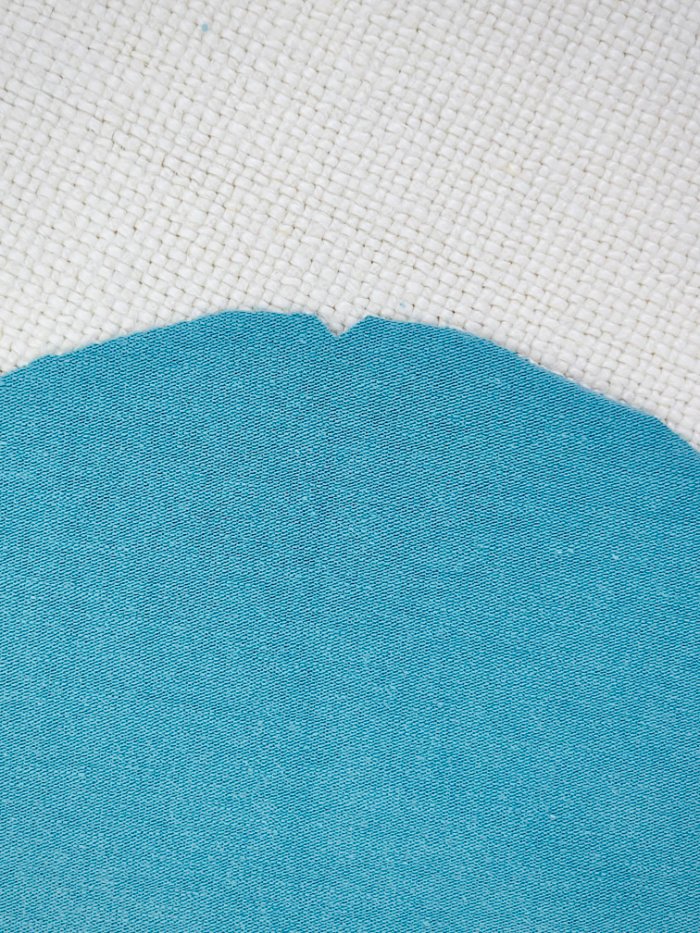

Cut the bodice pattern along the dotted line. When it comes to the neck opening, cut along the smaller neck opening for the back, leaving the deeper front neck line intact.

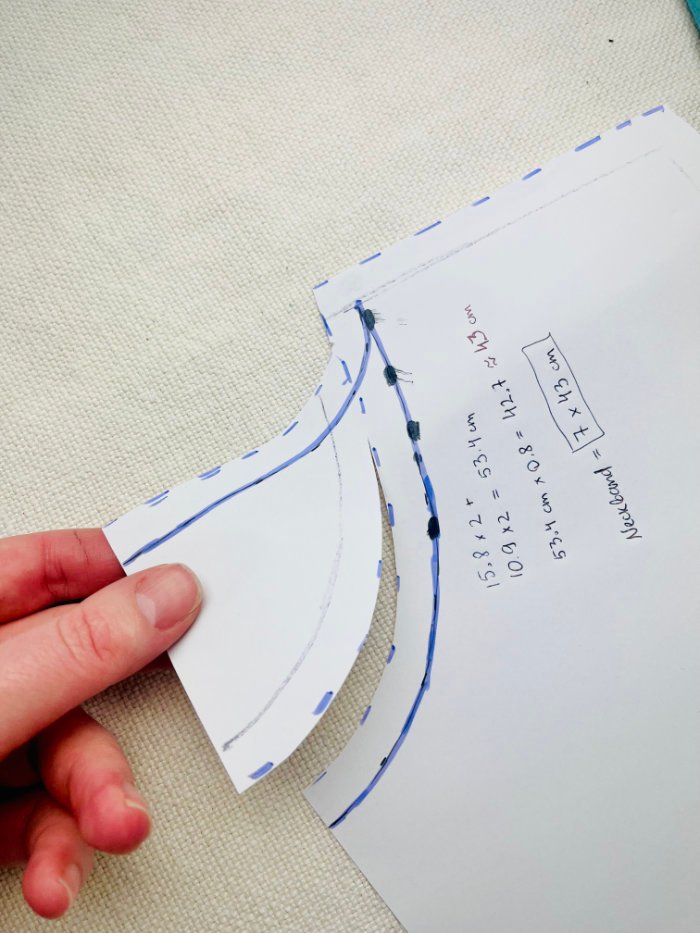

Drafting the Neckband

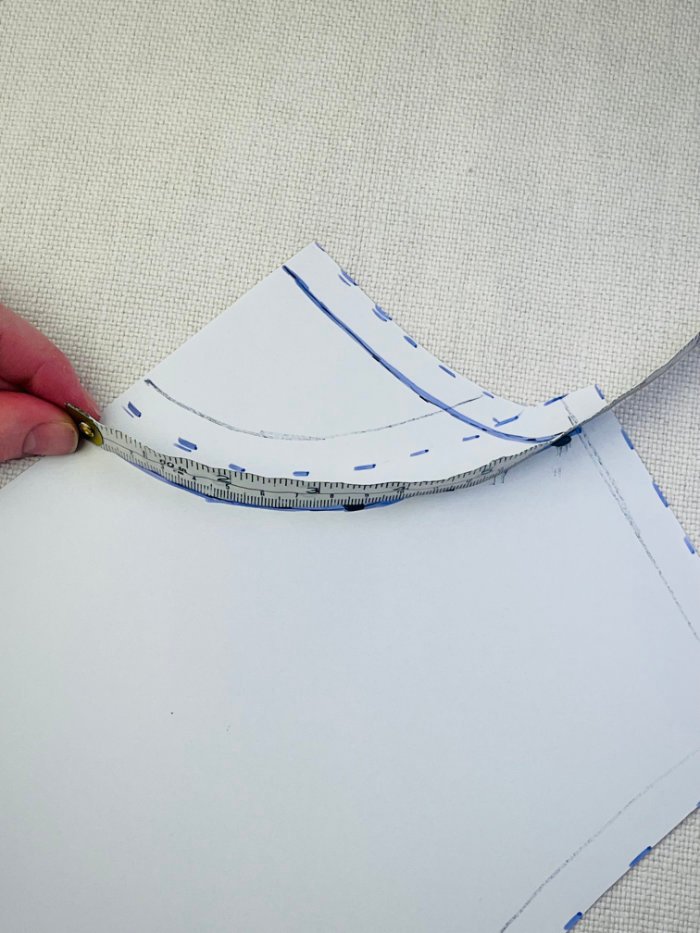

To create a neckband for the T-shirt, you will need to measure the neck length along the new neck line. Place the tape measure on its side, running from the centre fold line along the new solid neck line for the front. Take the measurement at the shoulder seam line. Repeat for the back neckline.

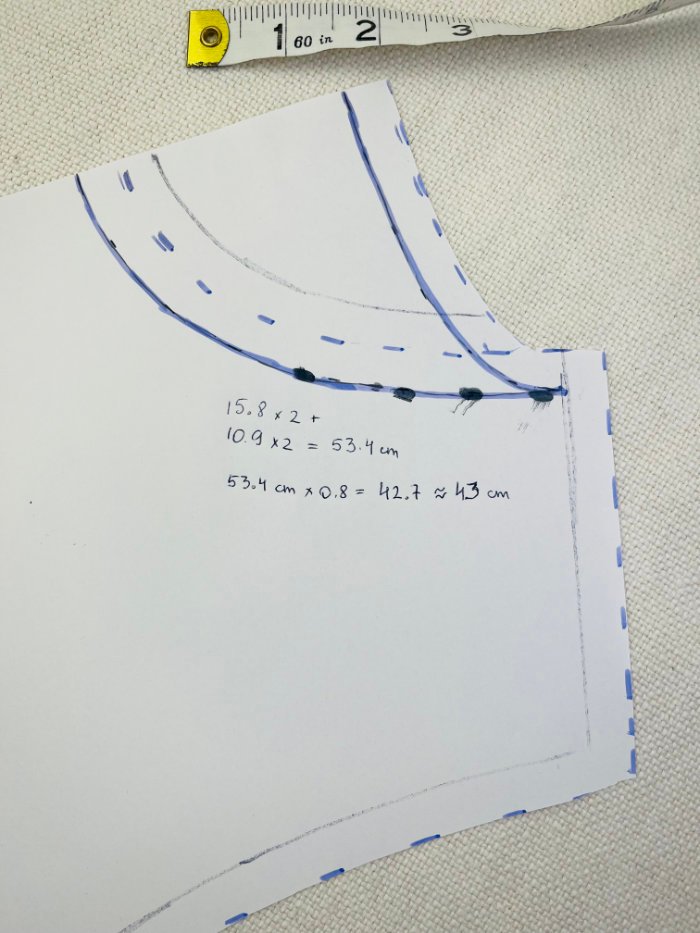

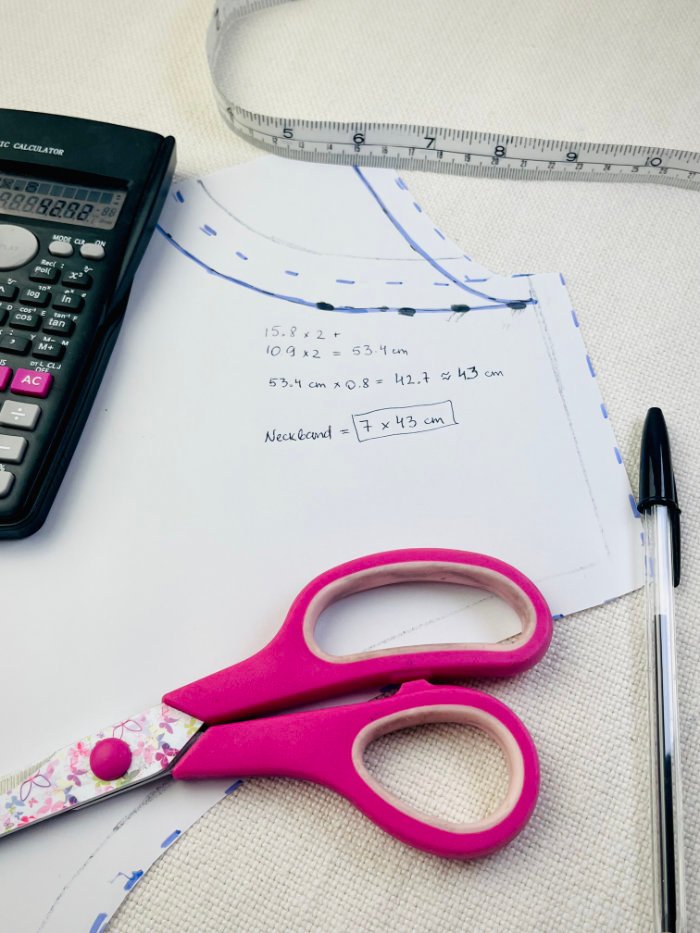

You have two measurements that both need to be multiplied by two and added together to create the total length of the neckline. In my case, my total neckline length is 53.4cm. To work out the length of the required neckband, multiply this number by 0.8 and round it up to next whole cm. My neckband length is 43 cm.

The width of the neckband is going to be 6 cm, which you get by multiplying the 2 cm for neckline adjustment measurement from the previous section by two and added 2 x 1cm seam allowance. I like to add additional 1cm to the width for slightly larger neck covering but you do not need to do it.

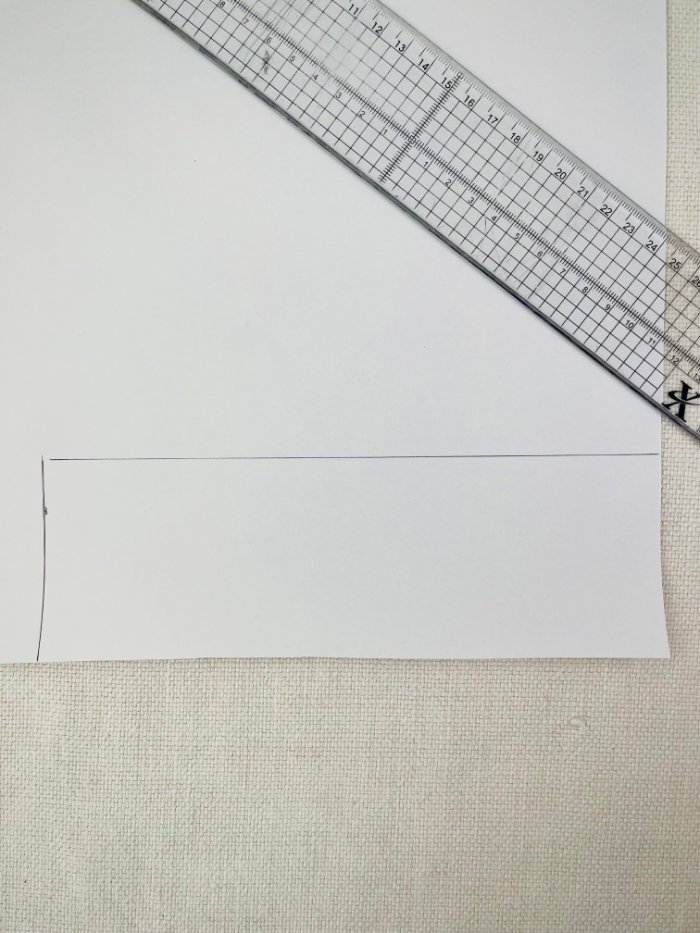

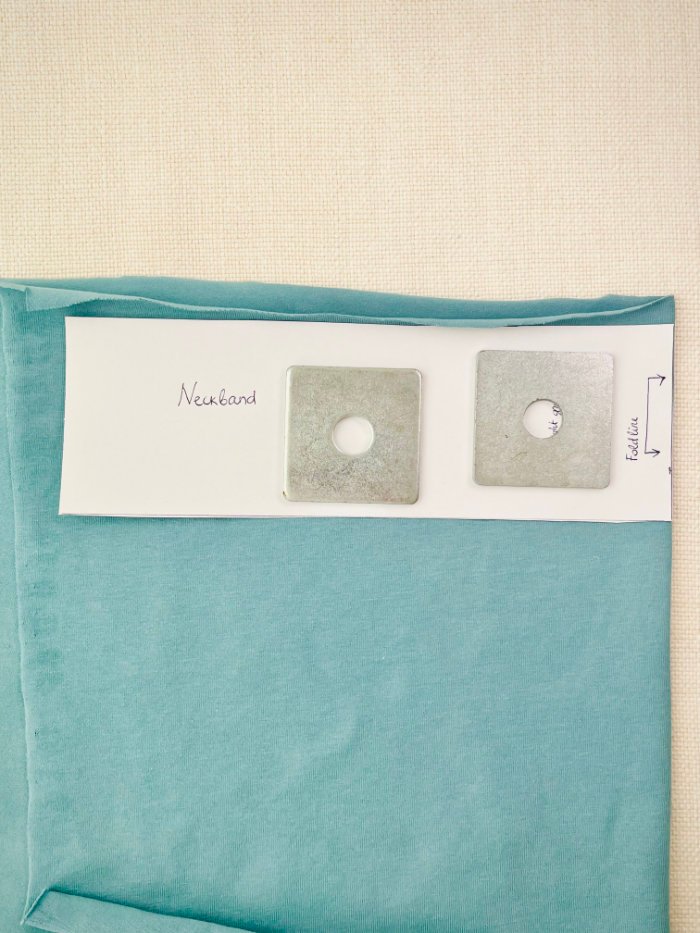

You have an option either to draw a neckband pattern that is exact measurements or make it a half length and mark a fold line on one shorter edge. I go for a half length to save the paper.

Adjusting Sleeve Length for 1 Metre of Fabric

As we are using 1m of the fabric to make the T-shirt, to work out the maximum sleeve length that we can use on the pattern, we need to measure the fabric, the bodice pattern and then work out the sleeve length with seam allowances included.

If you have more fabric to play with, you can totally trace the sleeve pattern block to the desired length and add the 1cm seam allowances for all the sides and crown, and 2cm hem allowance.

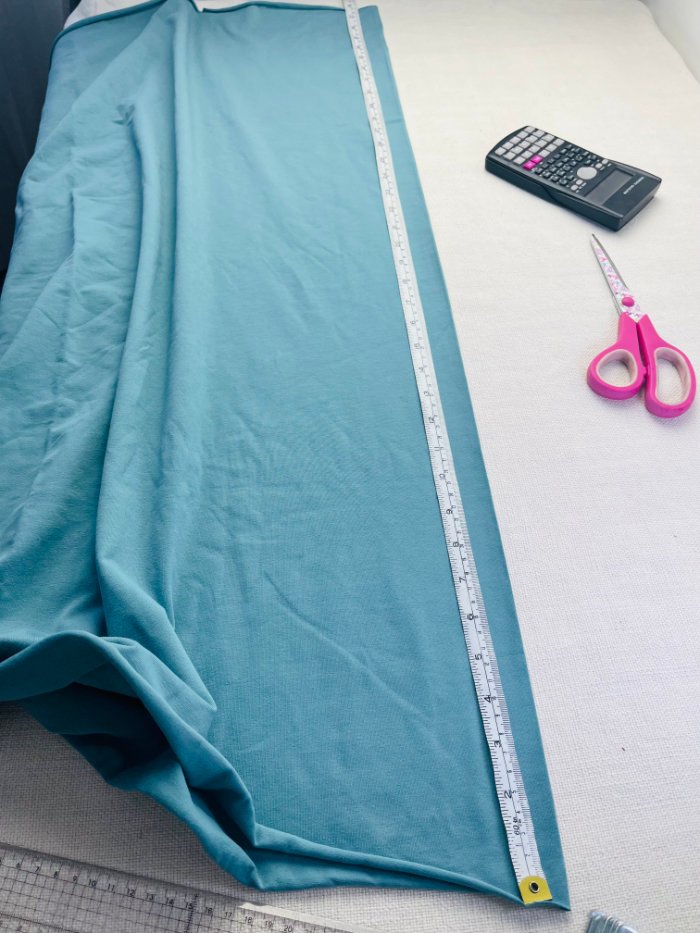

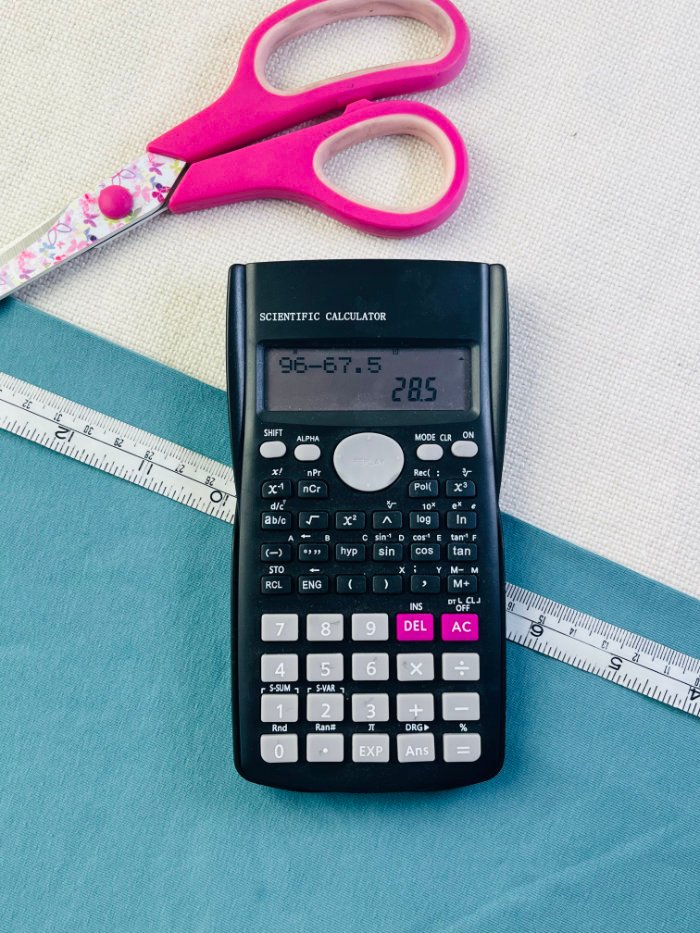

I start by measuring the total length of the cotton jersey I have. I bought the fabric as exactly 1 m, however I had pre-washed it previously and it has shrank a bit (you can read my article on fabric prewashing on the reasons why and when to do it). So now it currently measures as 96cm.

Then measure the length of the bodice pattern, from the highest point at the shoulder neck point, all the way to the hem.

Next, work out the difference. In my case, the maximum length for the sleeve pattern, including the seam allowances is 28.5cm.

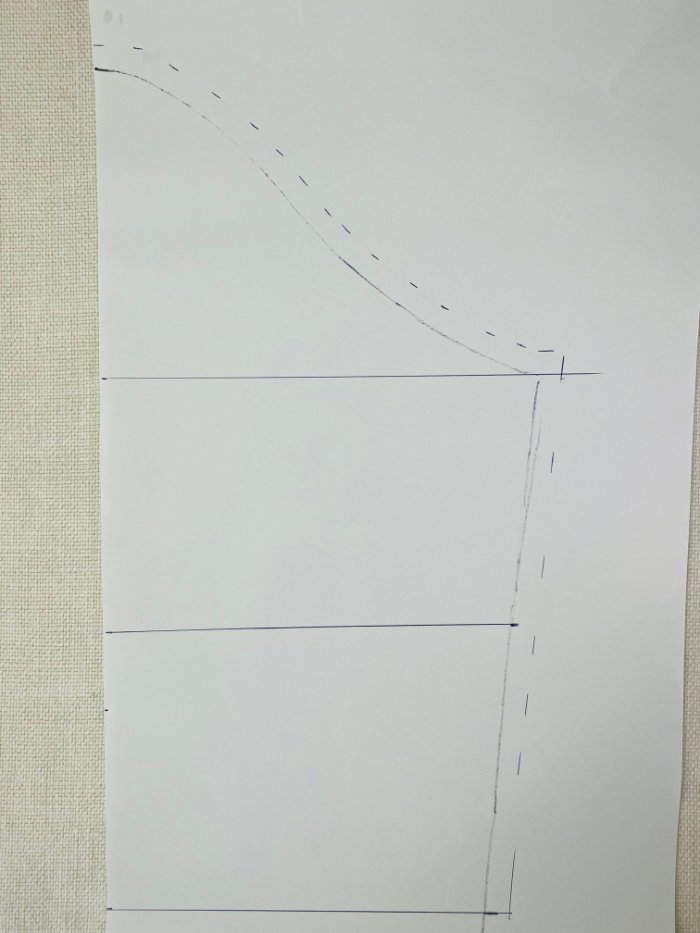

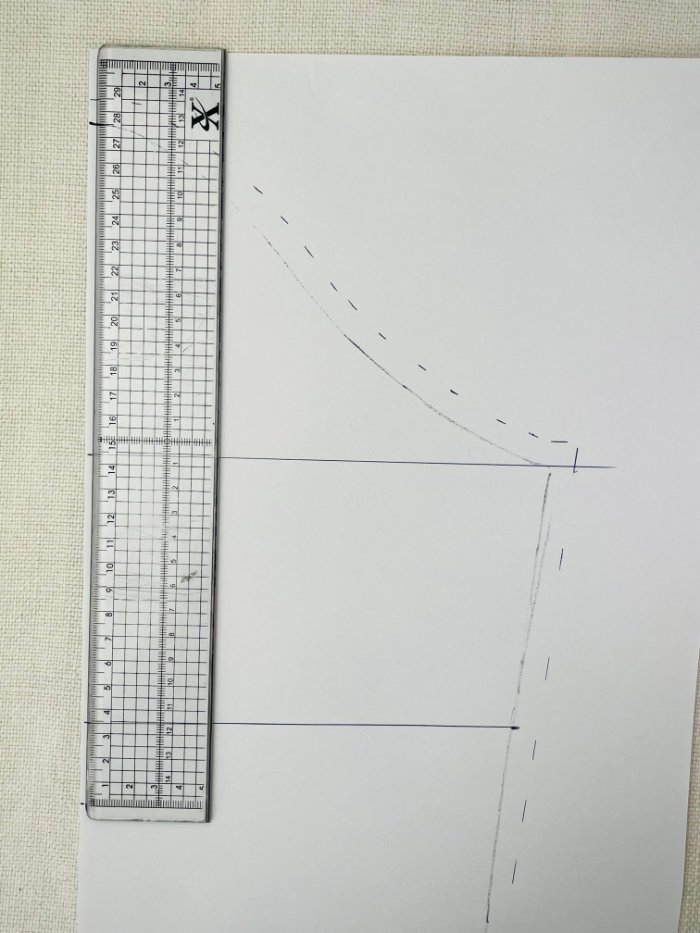

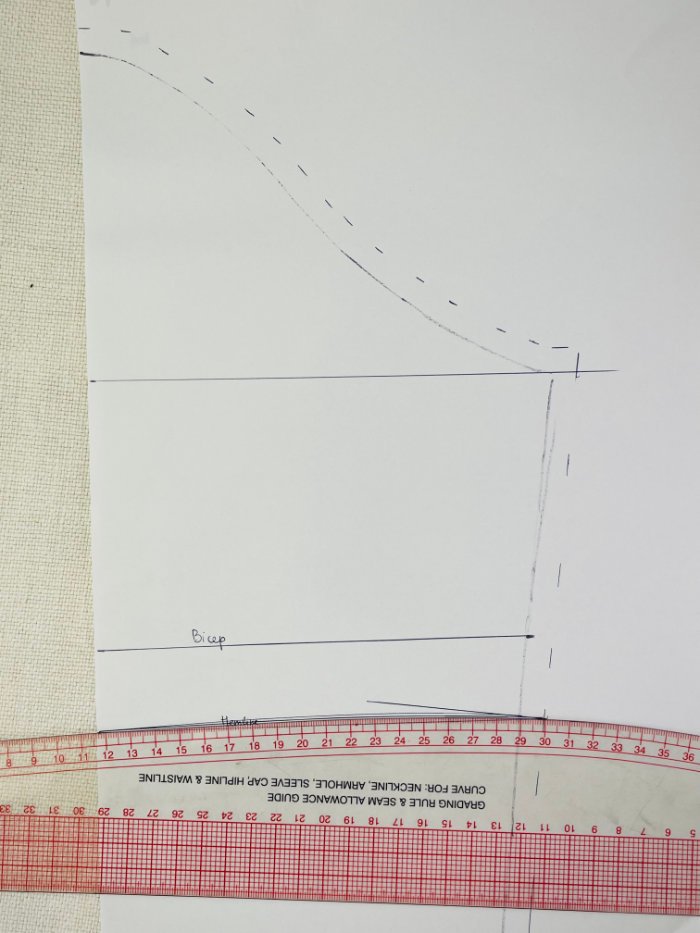

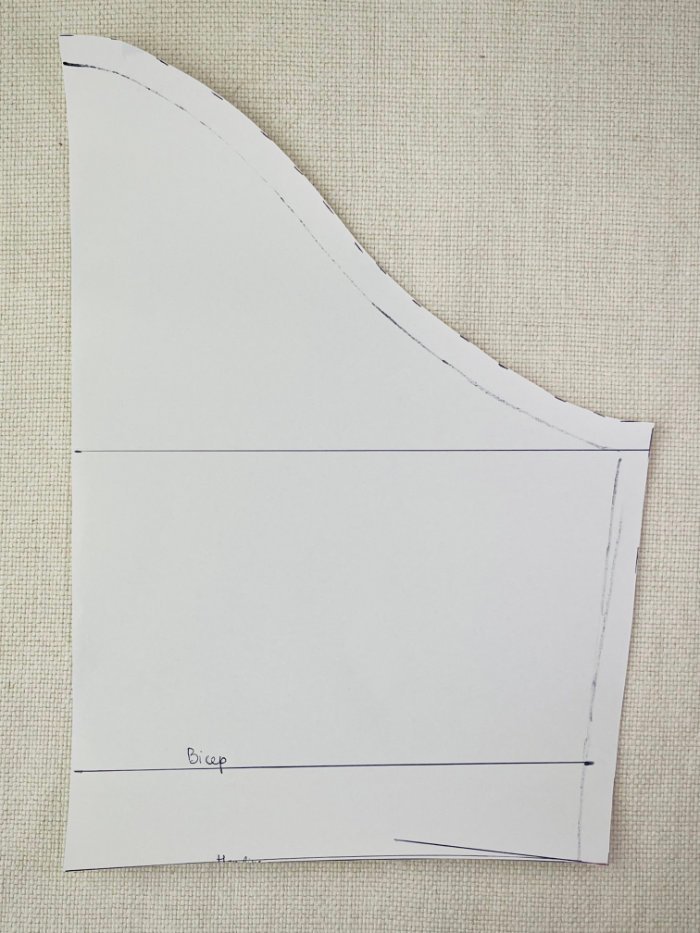

Place the sleeve block on a paper, with straight fold edge against the straight edge of the paper, leaving at least 1cm wide gap at the top. Trace around with a pencil.

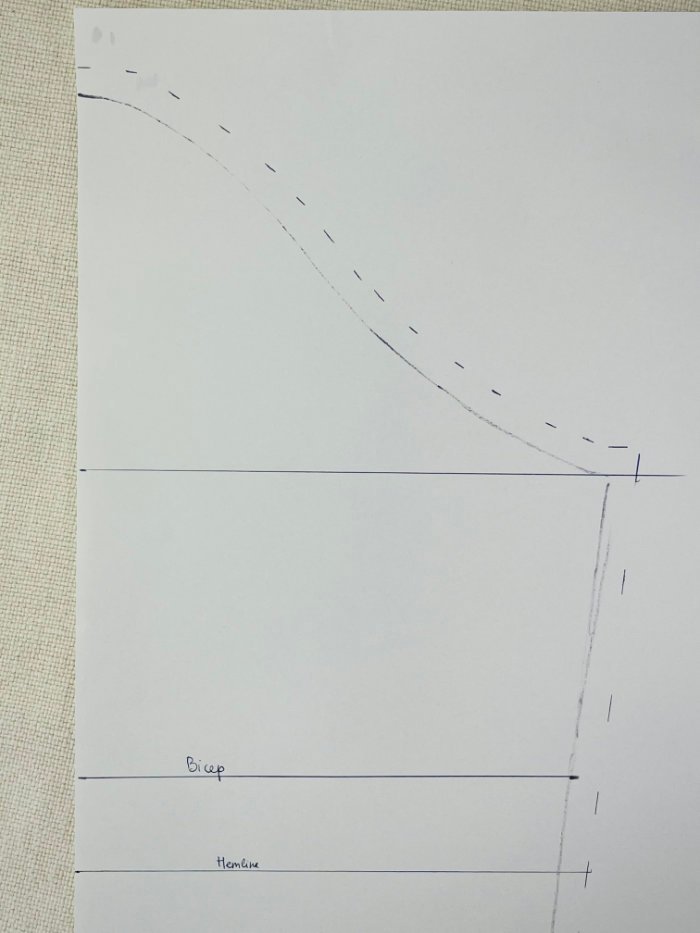

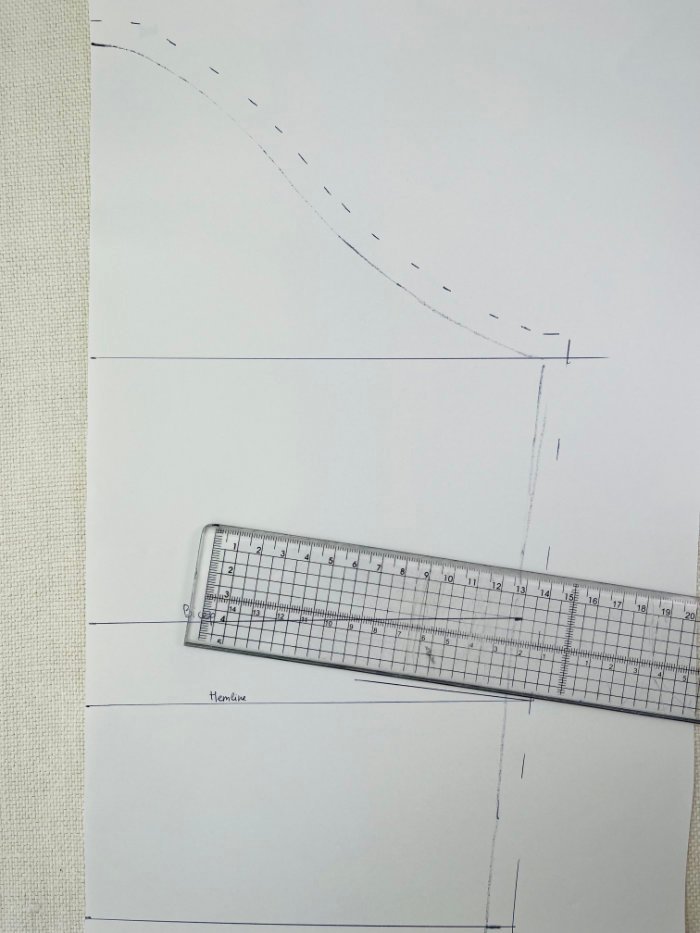

Then place the tape measure on the sleeve block, with 1cm mark at the sleeve crown. Mentally mark the location of the maximum allowable length for the sleeve. In my case it is just under the bicep line. Then trace around the sleeve block to just below this measurement.

Mark the bicep, elbow and armpit line on the paper, on the traced sleeve pattern by moving the block pattern slightly to right. Remove the block pattern and connect these marks to the side seam with a straight and squared line.

Add 1cm seam allowance all around, except for the hem as we have not marked it on the paper yet. The hem allowance is going to be 2cm but you do not need to mark it as it will be the maximum sleeve length available.

From the sleeve allowance at the sleeve crown, measure down the maximum sleeve length that you worked out earlier. Square across to the left and right to complete the sleeve pattern.

If you want to, you can correct the curve at the side seam to 90 degrees, however this is not necessary for short sleeve as the angle is not too wide and the correction is quite minor.

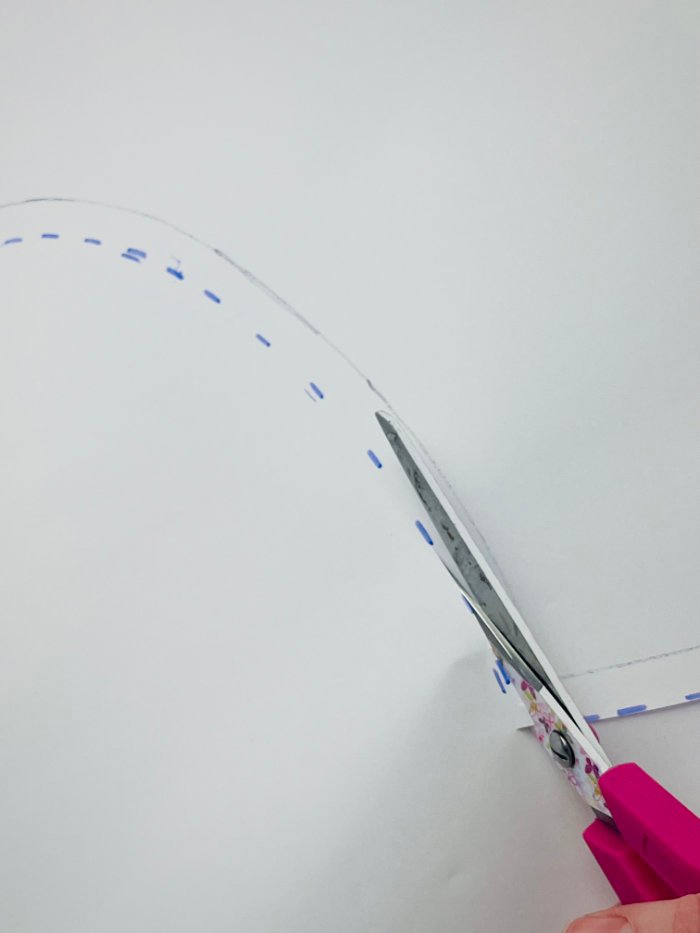

Then cut out the sleeve pattern along the seam allowance and new hemline.

Lastly, mark the fold line and grainline on all the pattern pieces.

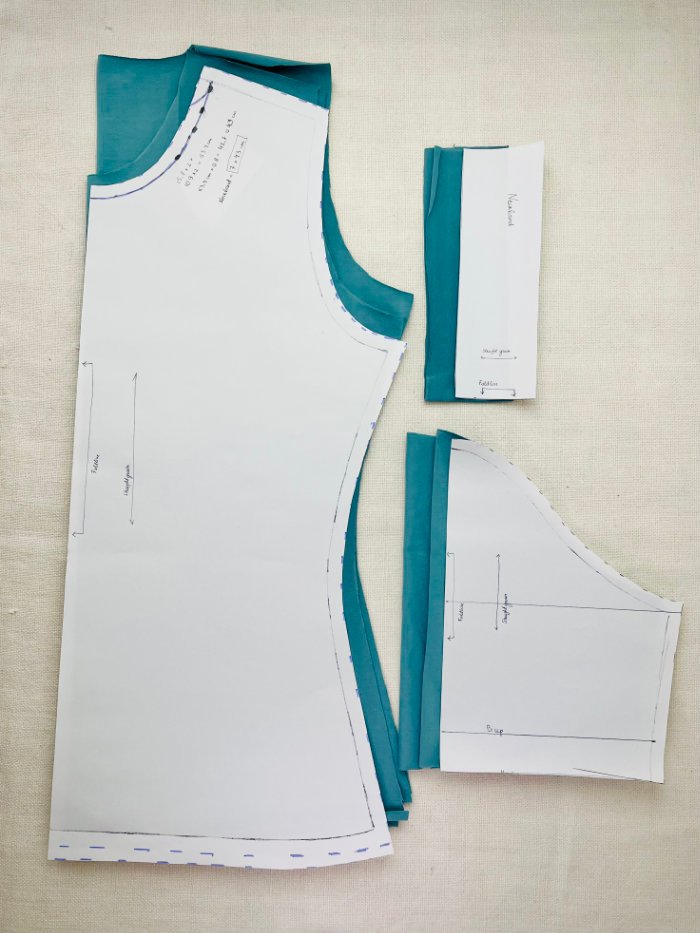

Step 2: Cutting the Fabric

All the pattern pieces will need to be cut on fold. If you are using a solid colour cotton jersey then you do not need to worry about the pattern placement. However, if you are using a directional pattern then you will need to make sure that all the pattern pieces are laid out on the fabric the same direction.

Cut the back bodice piece

The pattern that you have prepared has both the front and back bodice pieces in one pattern. As you cut out the pattern along the back bodice piece neck line, this is the first piece that you need to cut out.

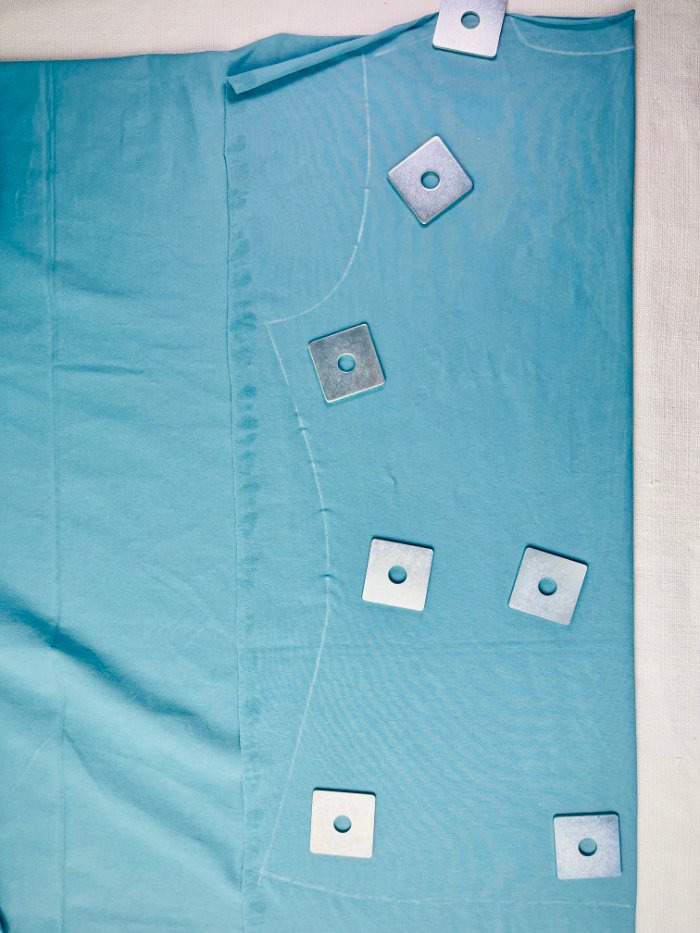

Let’s start by folding one edge of the fabric to the left to fit the bodice block. Then place the bodice block on top of it with the fold of the pattern in line with the cut edge of the fabric. With fabric weights or pins secure the pattern in place, then trace around with a soap, erasable fabric marker or chalk.

Carefully remove the pattern without disturbing the fabric. Place the fabric weights on top of the fabric or re-pin the layers. This is your back bodice piece.

Cut out the T-shirt back bodice piece, cutting both layers of fabric simultaneously.

Cutting out the front bodice piece for the T-shirt

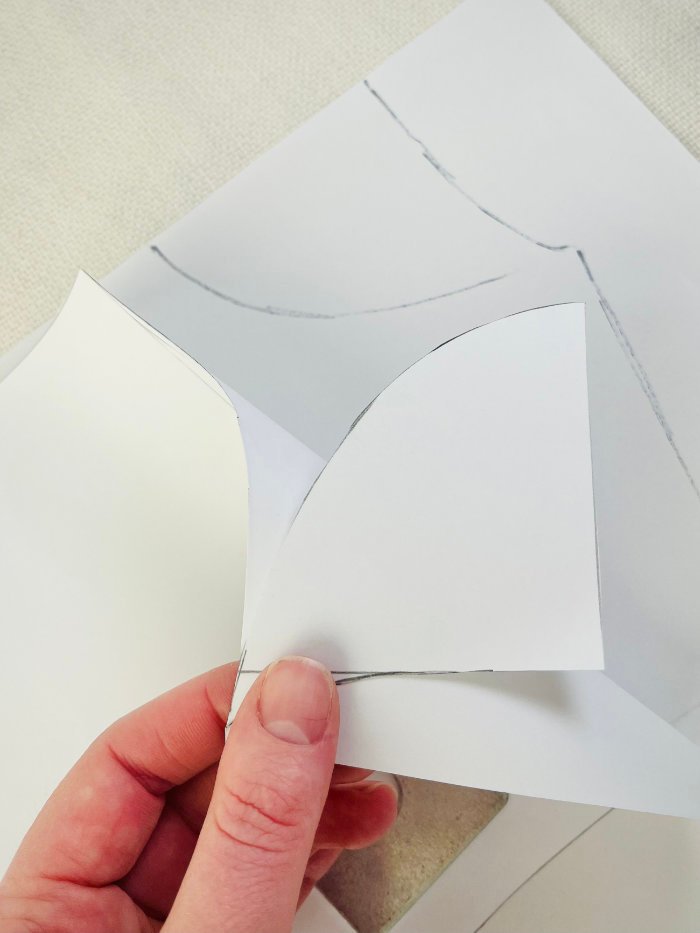

Next, cut the neck opening on the pattern along the front neck opening line, starting from the shoulder seam. Do not cut it all the way to the central front line, leave a little bit connected. Then fold the nearly cut off piece to the back. This will allow you to reuse the same pattern in the future.

Now you will need to cut the front bodice piece the same way as you did the back bodice piece. Make sure that the pattern is aligned with the same edge of the fabric that you aligned to the back pattern piece. This ensures that you will have enough fabric at the bottom part for the sleeves. You can turn the pattern piece upside down if you have a solid fabric or non directional pattern. This will reduce the waste.

Cutting T-shirt sleeves

Once you have cut out the bodice patterns, you should have enough fabric left to fit two sleeves. If you turned the front bodice part upside down, you may even have enough fabric on one edge of the fabric to fit one sleeve on top of the other.

As the sleeve patterns is designed to be cut on fold, you will need to fold the fabric to fit the pattern piece. Place the sleeve pattern on the folded fabric, with the fold lines aligned. Trace around and cut the same way as you did with the bodice pieces. You need to cut two sleeve pieces on fold.

Cutting the Neckband

On one edge of the fabric you should have enough width and length of the fabric left to fit a neckband.

If you created a half size neckband pattern, then fold the fabric to fit the neckband along the fold line. Trace and cut it the same as the other pattern pieces.

While you have all the pattern pieces folded in half, cut notches

- on the necklines to mark middle front and middle back

- on sleeve crown to mark the shoulder line

- on the neckband to mark the centre front

Step 3: Sewing a Fitted Jersey T-Shirt for Women

While most of the tutorial has been dedicated the pattern and fabric cutting, the sewing is actually quite quick and I can get a T-shirt cut and sewn up in less than 30 minutes! There are only 7 seams to sew, 3 hems to finish and an optional neckline topstitching.

Without further ado, let’s jump straight into the fun bit of sewing the T-shirt.

Sewing the neckband

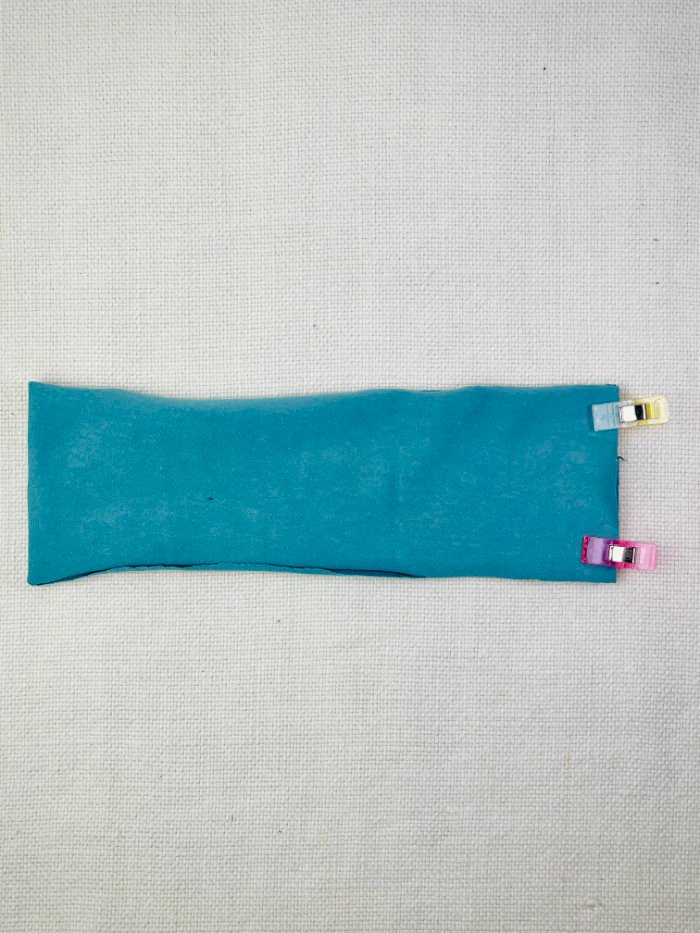

Fold the neckband short edge to short edge with right sides facing. Pin the short edge and then sew the seam with 1cm seam allowance with overlocker or zig zag stitch on the sewing machine. Press the seam flat to embed the stitching and reduce the waviness of the seam.

Then fold the sewn neckband in half long edge to long edge with right sides together and the sewn seam on the right. Fold the seams to the opposite directions to butt against each other to stop it from moving and to reduce the bulk.

Pin the raw edges together at the seam (this is going to be centre back) and on the opposite side where you have a notch for the centre front.

Bring both pins together on opposite sides and place further two pins on the crease lines as demonstrated. These additional pins will be shoulder notches.

Sewing shoulder seams

Place the back bodice on the table with right side facing up. Place the front bodice part over the back bodice with right sides facing and matching the shoulder seams. Pin the shoulder seams.

Then sew both shoulder seams with 1 cm seam allowance. You will need to sew the shoulder seams in the same direction in relation to neck opening. I.e., if you sew the first shoulder seams from armhole to neckline, then the other shoulder seam you also need to start from the armhole. This reduces any uneven neckline and armhole distortion if the fabric moves slightly during the sewing process.

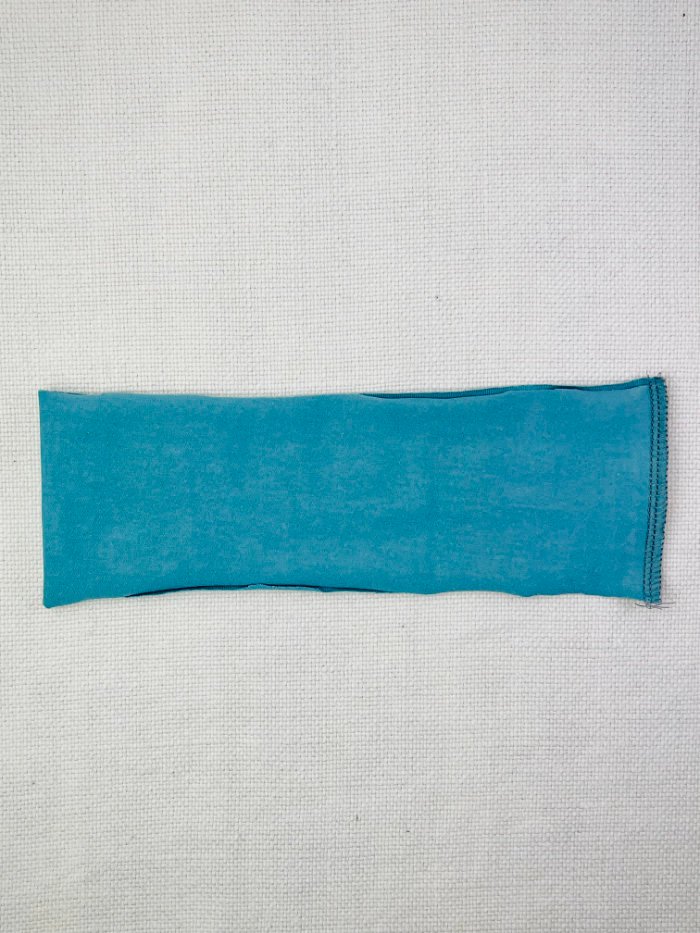

Press the shoulder seams flat to embed the stitching line and reduce the seam waviness.

Attaching the neckband

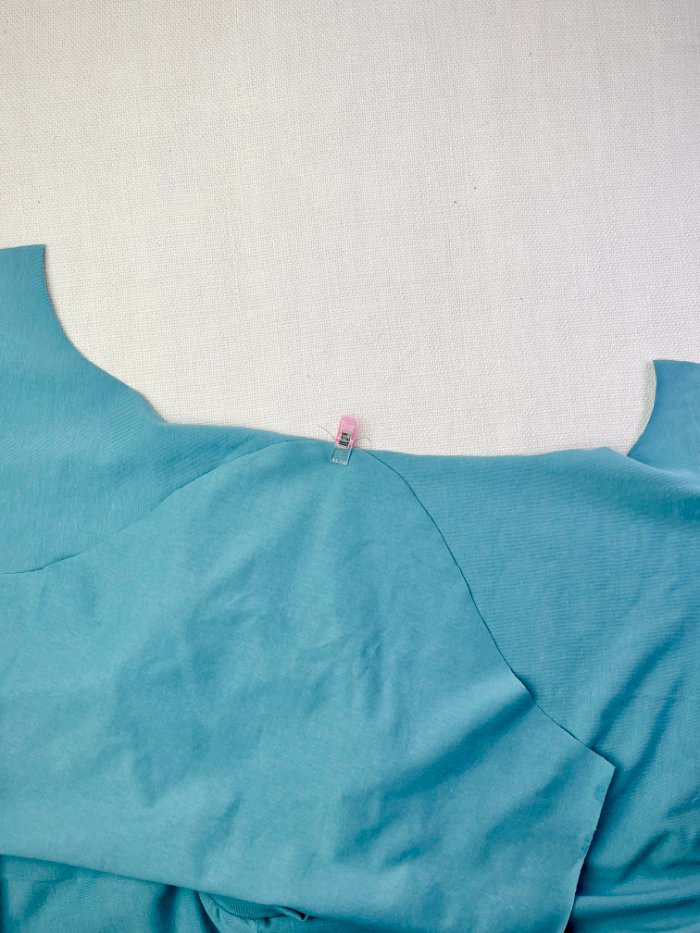

Now, place the sewn bodice part on the table with right sides up and neck opening visible.

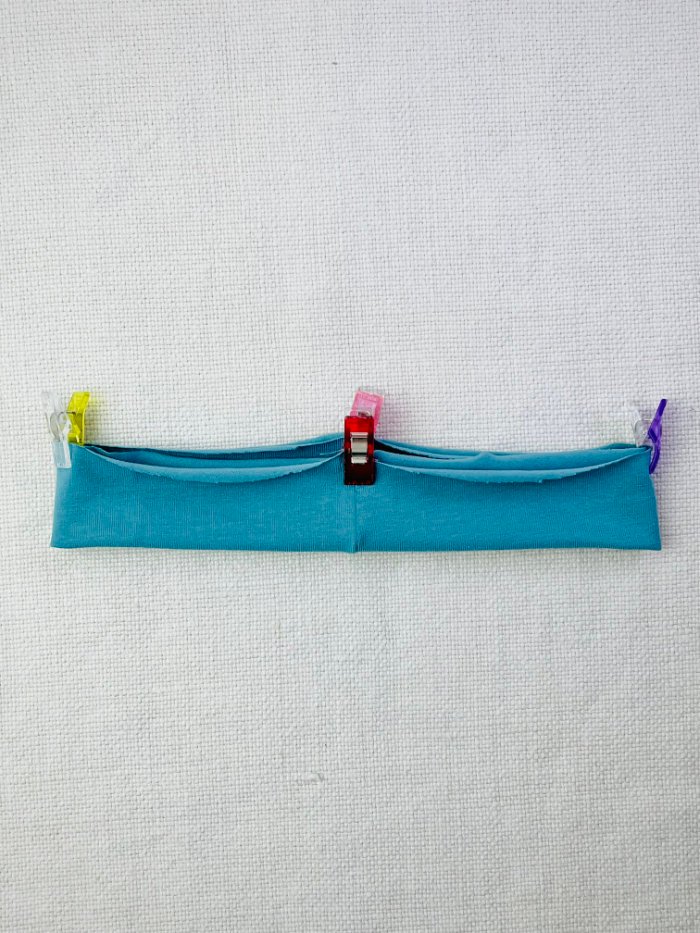

Pin the neckband to the T-shirt bodice with raw edges aligned and pins or clips matched with centre back and centre front notches and shoulder seams.

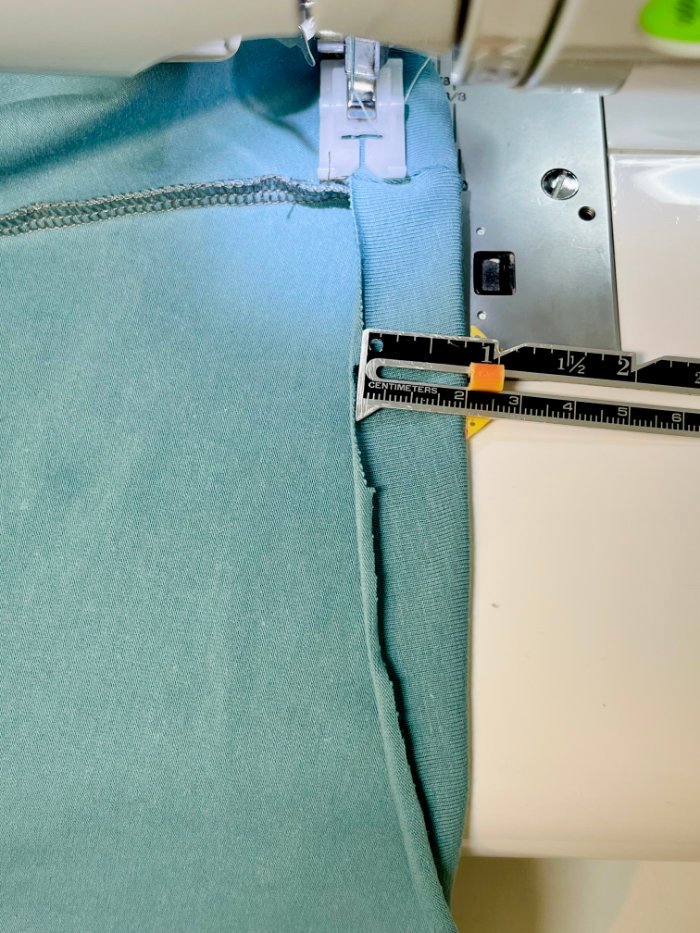

Then sew the neckband to the T-shirt bodice with overlocker or sewing machine with a zigzag stitch, Start before the back neck seam and backstitch if you are using sewing machine. When you start sewing, make a few stitches(annd backstitch on sewing machine if using) without pulling the neckband. Then lightly stretch the neckband to match the length of the bodice neckline. I find it easier to keep the bodice part at the bottom and the neckband on the top.

Sew all around, and overlap stitches when you have reach the starting point again.

Attaching Sleeves

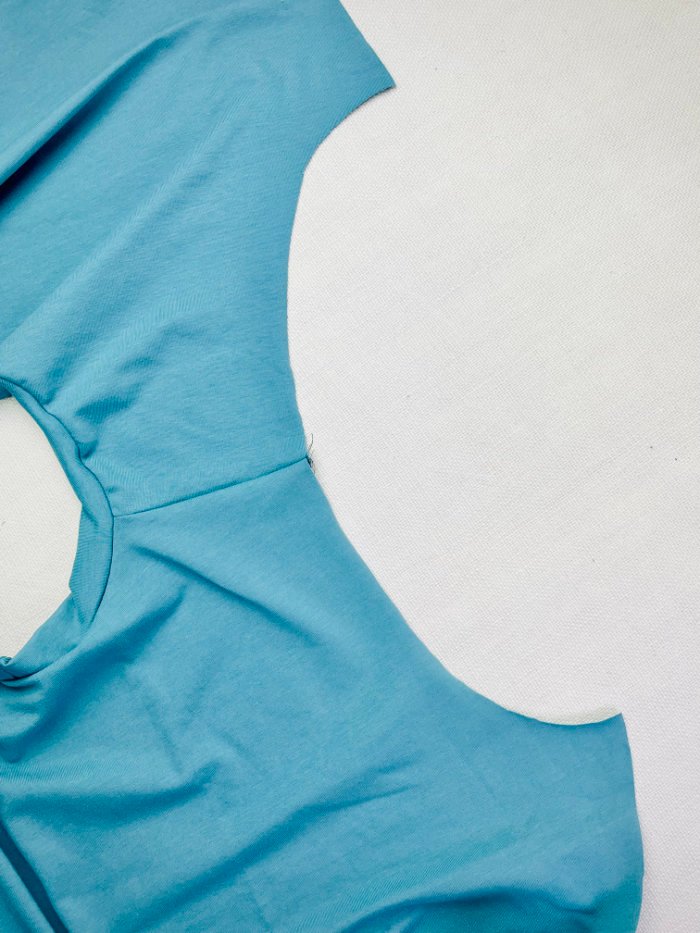

Lay the bodice part of the T-shirt on the table with right side facing up and the armhole flat.

Then, place one sleeve on top of the bodice with right sides facing and matching the notch on the sleeve with the shoulder seam. Pin in place at the shoulder seam.

Take the end of the sleeve armhole and match it with the end of the armhole on the bodice, pinning the first 3-4 cm before the point armhole starts to curve up.

Then, slightly stretch the bodice to fit the curve of the sleeve crown and pin in place.

Repeat the same on the other side to pin the whole sleeve to the bodice.

Next, attach the sleeve by overlocking or sewing with zigzag stitch.

Repeat the process with the other sleeve.

Sewing side seams

Place the side seams of the T-shirt together, with the right sides facing. Match the side seams at the sleeve and bodice seam line, facing the seams opposite direction to ensure smooth connection point. Pin in place this point first.

Overlock or sew with a zigzag seam, backstitching at the start and end.

Repeat with the other side seam.

Hemming the T-shirt

The hemming of the sleeves and the T-shirt hem is the same. Fold the hem up by 2 cm to the wrong side and with a narrow zigzag stitch sew the hem to the T-shirt (or sleeve), catching the raw edge. I am using a zig zag stitch with a 3mm width and 1.8mm length. Back stitch at the start and the end of the seam.

Repeat the same on the sleeve. While I sew the T-shirt hem from the wrong side of the garment, the sleeve hems I find easier to hem if they are right side out and I sew inside the sleeve.

Optional topstitching of the neckband

This step of topstitching the neckband is optional, however I find that the seam sits flatter and the neckband looks neater if I topstitch.

For this you can either use a special knit stitch that looks like a lightening bolt if you have one on your sewing machine or go for a zigzag stitch. I personally prefer the narrow zigzag stitch to match the hems.

Frequently Asked Questions

Final Thoughts and Conclusions

In this tutorial you learnt how to make a custom fitted T-shirt pattern from a basic T-shirt block with a matching sleeve, how to adjust the length of the T-shirt sleeve, cut the fabric, assemble and sew the T-shirt.

This tutorial shows exactly how to sew a fitted T-shirt for women from a custom pattern, making it easier to build a handmade wardrobe that fits and lasts.

Once drafted, this block can be reused indefinitely to create fitted T-shirts with different necklines, sleeve lengths, and fabrics.

Save this tutorial to Pinterest so you can reuse it every time you sew a knit T-shirt, and explore my pattern-drafting tutorials to build a fully custom wardrobe.