In my previous blog post I showed you how to create a custom bodice block from your own measurements. In this post I will explain how to take it from good to perfect template for your future sewing projects.

Short back story of personal experience

I still remember the feel of how exciting it was to create my first ever custom bodice block! I had already created a custom skirt block and this felt like another level of achievement. However, unlike the skirt block which was pretty straightforward to use, the bodice block appeared to require little more preparation work before it could be used successfully. Of course, it did not stop me and I actually made some dresses with the bodice block as is with an addition of some circle skirt and a zip. It worked!

Now that a few more moons have passed (quite a lot of them, actually), I am a little wiser and know a few tricks to creating a bodice block that truly became a template for other sewing patterns.

Trueing the corners of the custom bodice block

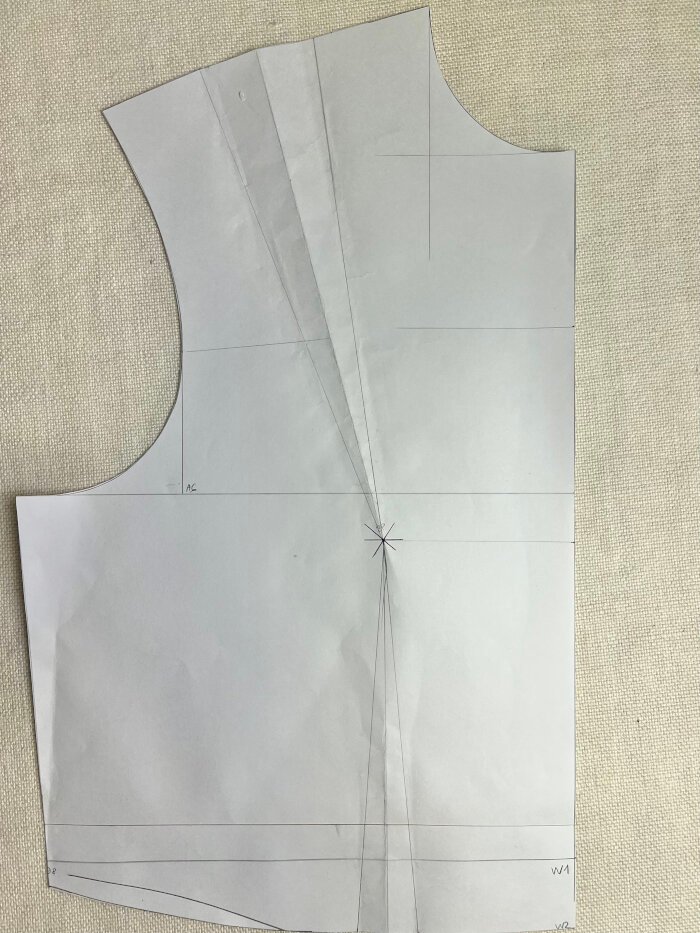

The very first thing that you need to do, is cut out the custom bodice block that you drafted earlier. Before you get scissor happy, add a star shape thing at the bust point, to allow you to match up the front pieces at the bust points later on.

Then, cut out all the front and back bodice pieces, cutting out the gaps for darts. Now you will notice why I asked you to mark that bust point – the front bodice part becomes two pieces! No, you have not cut it out wrong, it is just as it should be! The darts end at the highest point and for the front pice both the shoulder and the waist darts end at the bust apex.

Let’s move on to check whether the pieces aer seamlessly flowing into each other.

Adjusting shoulder line after closing bodice block darts

When the darts are closed together, there may be some dips at the shoulders both for the front and the back bodice block pieces. Let’s check and correct them.

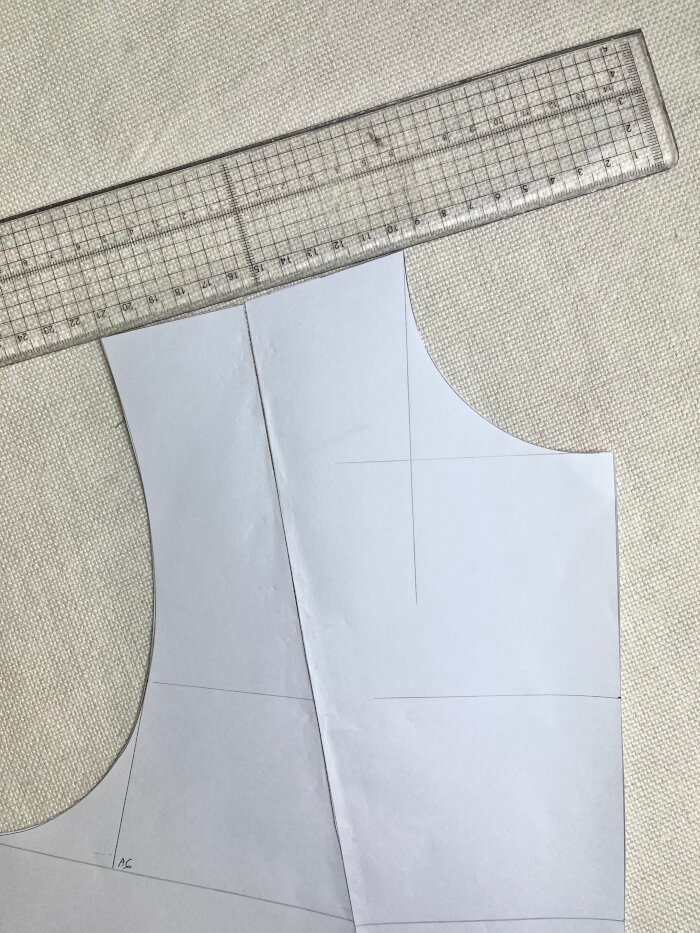

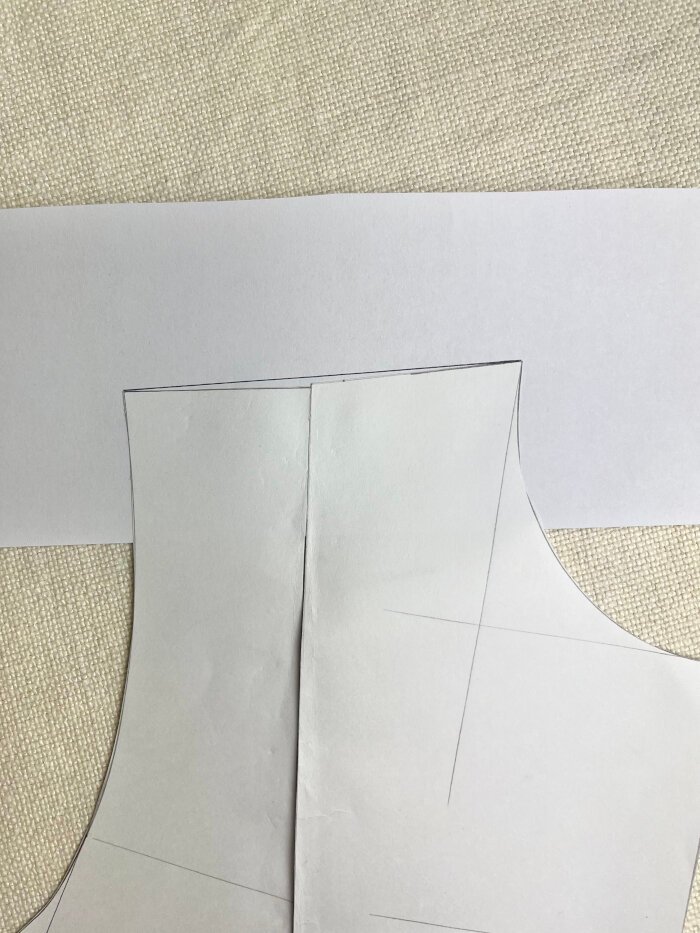

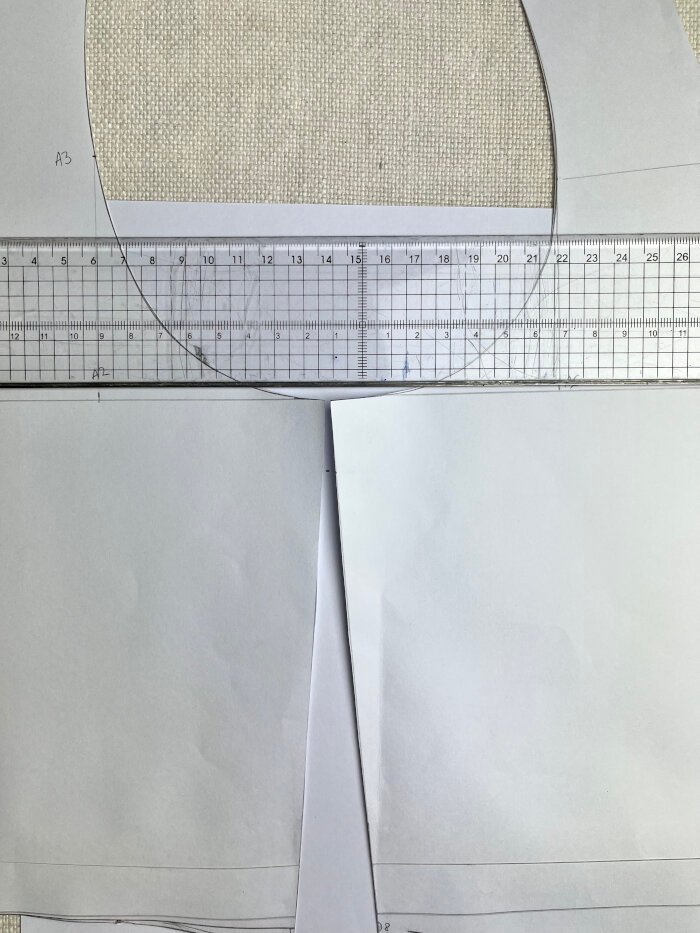

Place the front pattern pieces together to close the shoulder dart. Place a ruler next to it, connecting the end points of the shoulder. If the line is not straight, i.e., it does not follow the edge of the ruler, you have a dip issue.

To correct it, glue the wrong side of the front bodice block pieces onto a straight piece of paper, closing the dart as sewn. Then draw a line to connect the shoulder end points. Cut the pattern pieces apart, following the new shoulder line.

Check the back shoulder dart the same way. If there is a dip, follow the above steps to correct it. Be careful not to flatten the dart while making any corrections.

Adjusting the side seams of the custom bodice blocks

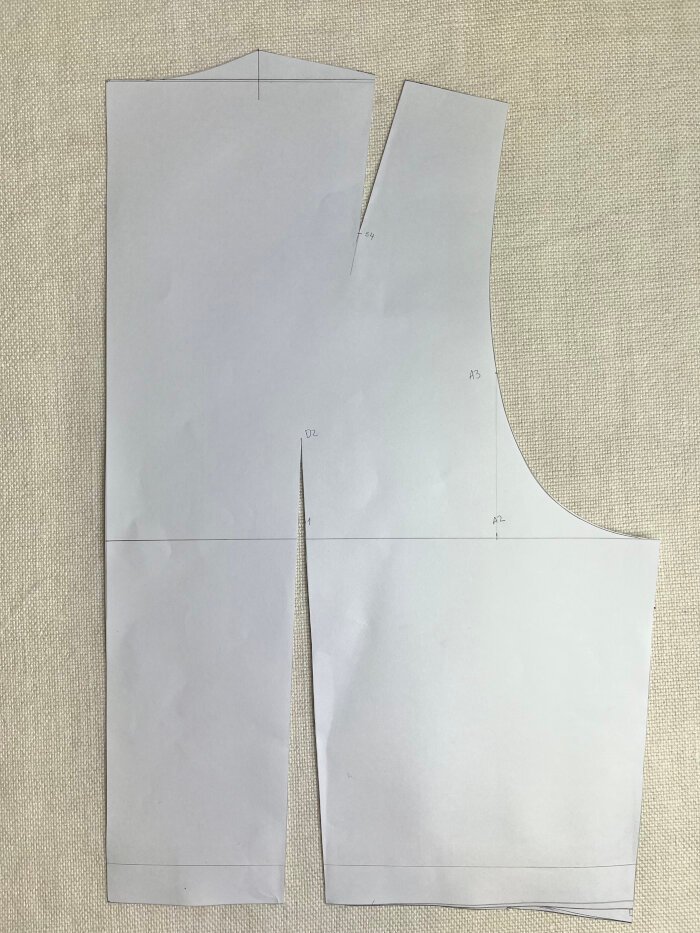

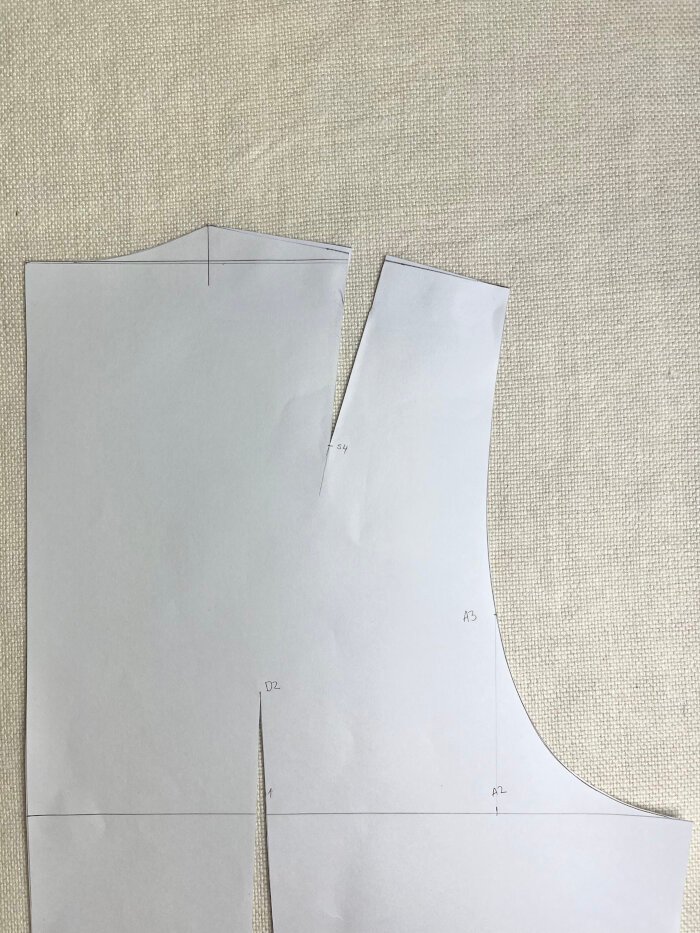

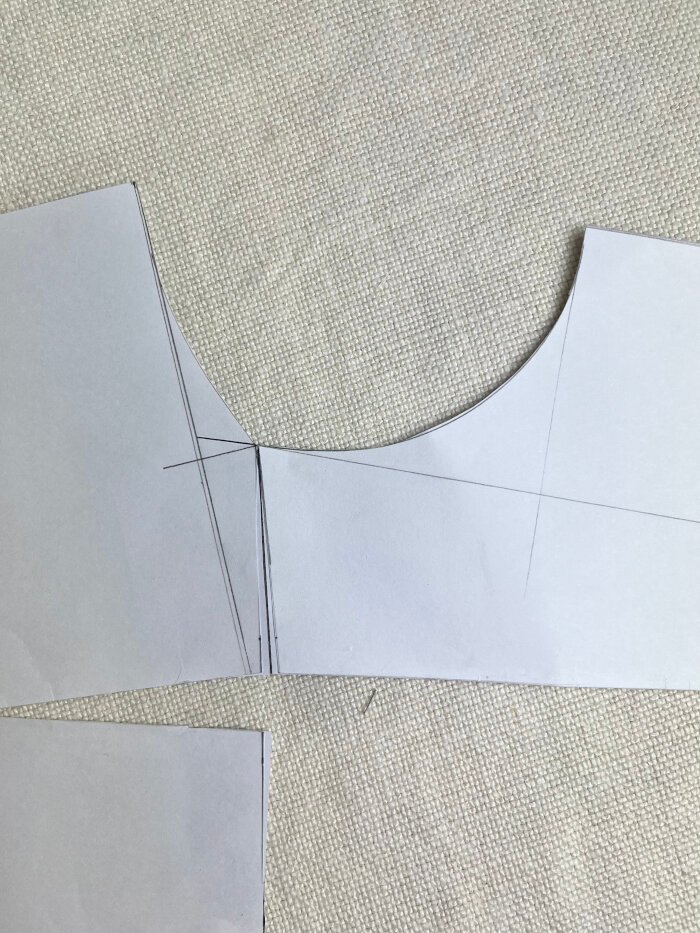

Next you need to check whether the arm scythe flows nicely into each other. To do that, bring the side front pattern piece and the back pattern piece together at the side seams.

Then place a ruler along the lower part of the arm scythe. What you want to check is whether the sides seams create a straight or smooth curved line at the arm scythe. look for any “hills” or dips on the armhole. This will vary from pattern block to pattern block and will depend on your personal measurements when drafting the bodice block patterns. If there is a dip, correct it the same way as you did the shoulder darts.

In my case, I have a “hill” or ridge that i need to smooth out. If you have the same outcome, draw a short straight line between the blocks to remove the “hill”. Then cut along the drafted line. Be careful that the ends of the straight line connects smoothly with the armhole line.

Adjusting the neckline of the custom bodice blocks

It is quite tricky to get a smooth connections points at the neckline at the drafting stage. It is possible but requires some calculations and manipulations with the old trusted protractor. I do not tend to mess with it for this area as it simply is easier to line up the custom bodice block pattern and correct the curves.

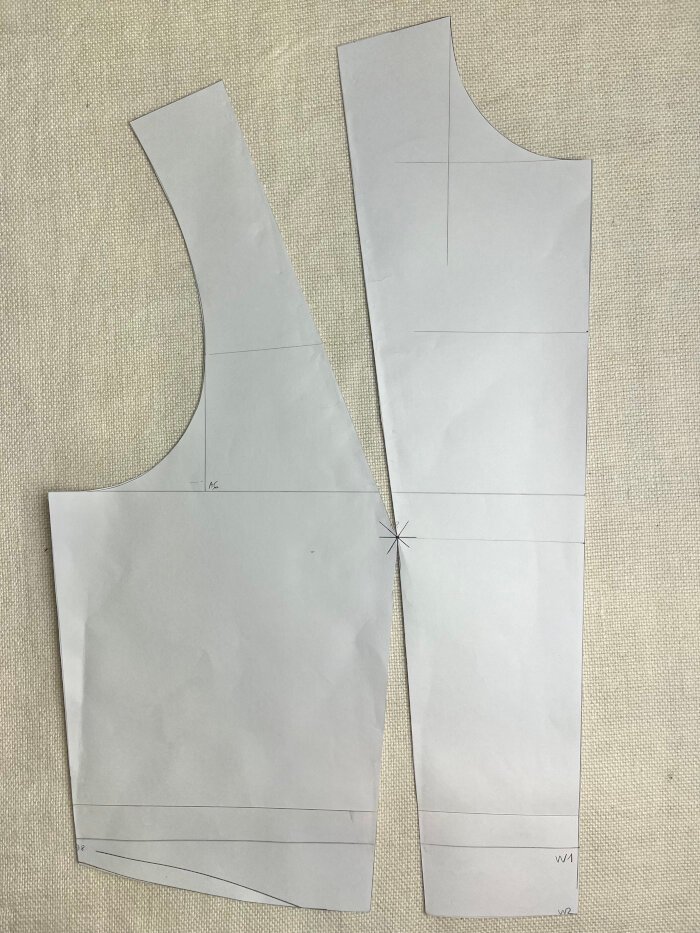

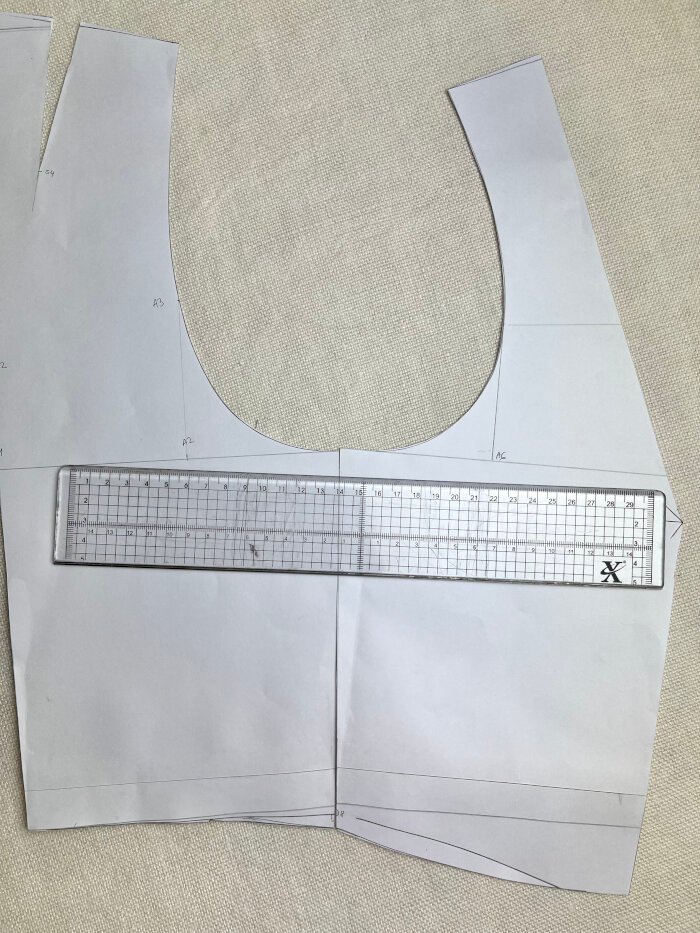

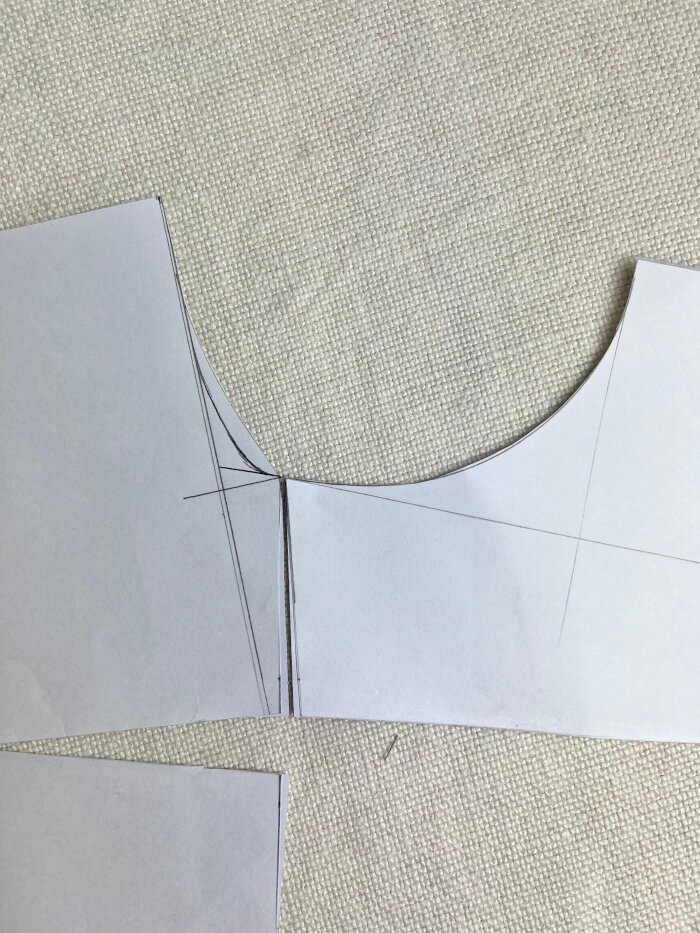

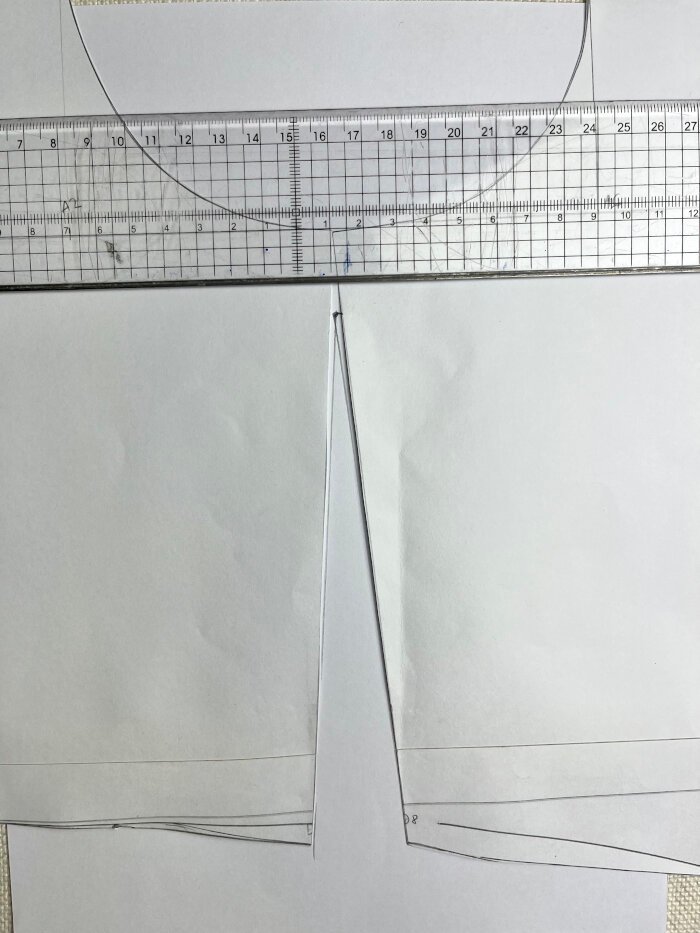

So, let’s line up the pattern pieces, by matching the back bodice block to front central piece bodice block at the shoulder seams.

You will see that mine goes into quite a sharp angle. We want to avoid that.

Your options for similar situation is either additng extra paper to raise the curve (the same as we did above) or by moving the point at which the neckline bends a little to the back. I have gone for the latter option.

Extend the a straight line from the front bodice neckline to the back piece. Then draw a new, smoothed back neckline free hand or by using a french curve. Next, cut it out along the drawn guide.

Adjusting the armhole at the shoulder transition

Line up the shoulders at the outside edge, to check the transition at the armhole. If there are any ridges or dips, correct the same way as you did the side seams for the ridge or shoulders for the dip. This area tends to correct itself hen you correct the darts at the shoulder. So, in my example, I already have a smooth line / curve in this area.

Correcting the waistline of the custom bodice block

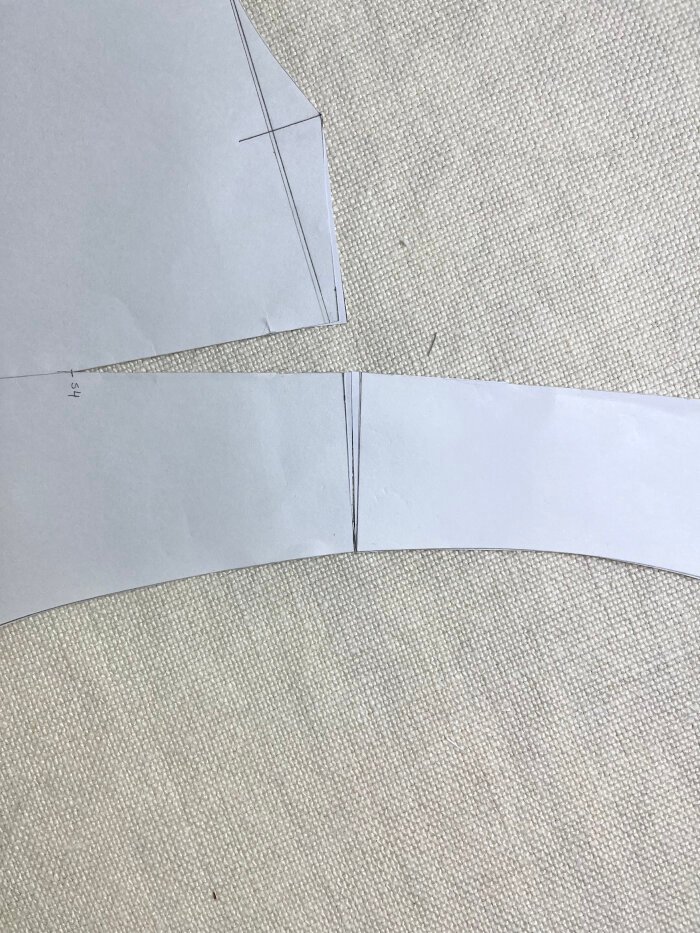

The last area that needs checking is the waistline. While the waist line was smoothed out at the pattern drafting stage (see my previous post), it is prudent to check it again once the darts have been removed.

Place all the pattern pieces together, seam to seam, as if it was sewn together. Critically assess the waistline, paying attention to odd areas where the curve may appear too narrow or too wide.

Redraw the waistline with french curve, removing the areas that are not as expected. Cut off the unwanted pieces.

Check the bust ease allowance on the bodice block

If you followed along the basic bodice block tutorial, then you noted that I added 6cm ease to bust and waistline. This would work out as 1.5cm on each of the bodice block. However, your bust most likely will have less than this ease added.

Why, I hear you ask. Well, the bust line in most circumstances are located below the armscythe. And the bodice block width at the lowest point of the arm scythe is the same as intended bust width. But, because the dart starts at the lowest point of the armscythe, the bust circumference is reduced.

This is not an issue, it is just something to remember for future modification and pattern designs.

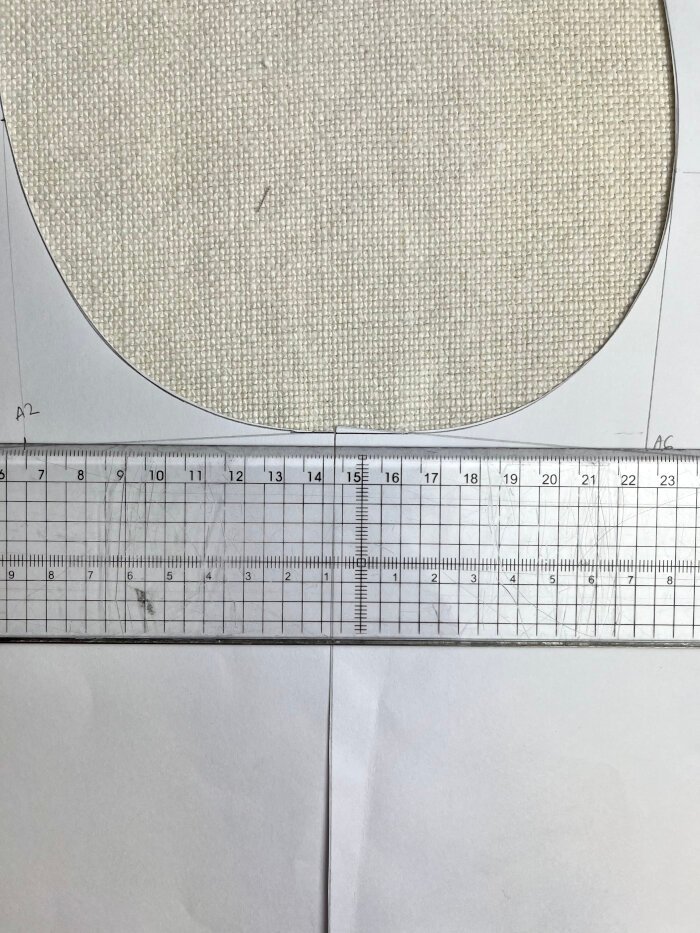

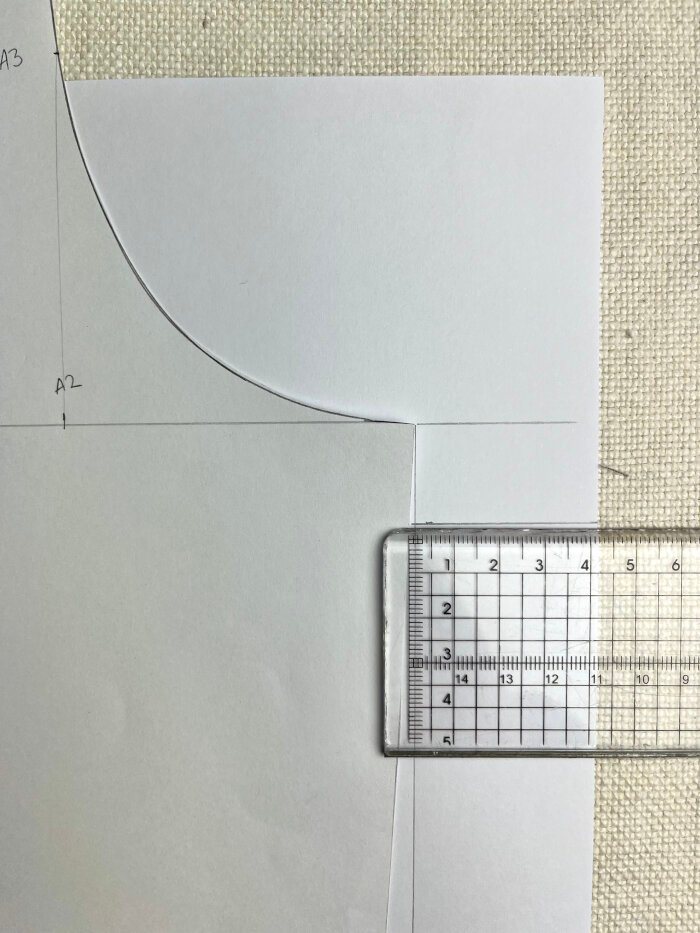

However, it is prudent to remeasure how much width you lost at bust point. To do that, place the front bodice block (the side part) on a piece of A4 paper with the top edge in line with the armhole line. Then square down from the armhole. Measure the distance on the front panel from the armhole line to the bust point. Draw a line that is this distance below the armhole on the A4 paper, touching the line squared down from the armhole.

Then measure the distance between the front bodice block and the line you squared down from the armhole, along the line you just drew . If the distance is smaller than 1.5cm, then no further action is required. My block only has a few mm difference so I do not need to make any changes.

However, if the distance exceeds 1.5cm, then you will need to reduce the width of one or all darts by the required amount to get the distance below the 1.5cm. Alternatively, and this is probably the simpler solution, start the side dart at the bust line, rather than the armhole line.

To do that, glue the back and the side pattern pieces on a piece of paper, ensuring the armhole line continues seamlessly and straight across both pieces, and the pattern pieces meet at the armhole point. Connect both patterns with a line that is drawn in level with bust point (measure the required distance as above). Then, find the middle point between the front and back bodice patterns along the extended bust line. This will be the top of the dart. Connect this point to the dart start points on the waistline.

Cut the along the new dart lines. Finally, recheck the waistline as advised in the previous section.

Test the custom bodice block

Once all the adjustments and corrections are made, test the pattern, by making a toil. If you took accurate measurements, then the pattern should fit as expected. However, there may be some body specific reasons why further adjustments to bodice block may be required.

If you make any adjustments, do not forget to transfer them back to the bodice blocks.

Create a clean master copy of the bodice block

When you are happy with the fit of the bodice block, make a copy of it on a sturdier materials, like a cardboard. This will make the tracing of the block for specific design projects easier and you will always be able to refer back to it.

I make my master copy on a colourful paper and hang it on a trouser hanger in my workplace, so that I always know where it is, and it stands out amongst the working patterns. This reduces a chance of accidentally cutting or destroying the master copy.

Conclusions

While, strictly speaking, none of the adjustments are required to make a successful design pattern and garments, making the suggested corrections on the custom bodice block will save you a lot of headache, and make the design pattern a success from the get go.

Subscribe to my newsletter if you want to learn how to make design patterns and how to use the bodice block for your sewing projects.