In this blog post I will show you how to add seam allowance to your drafted or traced sewing pattern at the drafting and cutting stage.

I draft my own garment patterns for personal wear and blog tutorials, working primarily with natural fibres such as cotton, linen, hemp, rayon, and wool. The seam allowance recommendations in this guide are based on hands-on pattern drafting, garment construction, and fabric testing rather than generic commercial pattern defaults.

Sewing patterns are typically drafted without seam allowances so the design can be transferred cleanly from a basic block to a finished pattern before construction details are added. The seam allowances are then added once the design is completed. Most commercial sewing patterns include seam allowances, but the width varies by brand and fabric type, making it important to verify allowances before adjusting or sewing.

If you draft sewing patterns from scratch, trace garments, or create DIY patterns, understanding seam allowances is essential for accuracy and garment longevity.

Who this guide is for:

This tutorial is designed for home sewists who draft or trace their own patterns, adjust existing patterns, or sew with natural fabrics where seam allowance choice directly affects durability, finish, and fit.

When to Add Seam Allowance to a Sewing Pattern

You have a choice of adding seam allowances at the paper cutting or fabric cutting stage. Both methods are valid and provide the same outcome.

Adding Seam Allowances to the Paper Pattern (Pros and Cons)

If you add the seam allowance tot he paper pattern, then the planning of the fabric cutting becomes easier. You can position the paper patterns on the fabric without worrying about leaving enough gap for added seam or hem allowances. The fabric cutting becomes a quick tasks as you do not need to trace the pattern and . or sea allowance and can cut with rotary cutter or scissors along the edge of the paper pattern.

On the flip side, any future pattern manipulations would mean that you have to redraft or retrace the whole pattern again. The other con of adding seam allowances to the paper pattern is that the pattern would be made just for the same fabric weight and does not take into account specifics of the material or seam finishes. E.g., wool melton will require more seam allowance compared to plain cotton weave.

You can keep several patterns at the same time – one for the design amendments and others with seam allowances included for various types of fabric and their weights that you may want to sew.

Adding Seam Allowances During Fabric Cutting (Pros and Cons)

Adding seam allowance to the fabric reduces the number of paper patterns that you need to keep or create. This reduces the storage requirement for various pattern variations. You also can adjust the seam allowances for the type of fabric or seam finish that you are using. E.g., for French seams you would require larger seam allowance compared to standard seam.

However, if you add seam allowance at the fabric cutting stage, you need to keep in mind how much seam allowance you need to leave for side seams versus hems. This slows down the cutting stage as you need to plan the cutting layout carefully to reduce the fabric wastage.

Comparison Summary

The table below compares adding seam allowances on the paper pattern versus adding them directly to the fabric, so you can choose the method that best fits your workflow.

| Area for consideration | SA on Paper pattern | SA added on Fabric |

|---|---|---|

| Design Adjustments | Not possible without retracing the pattern without seam allowances | Can adjust the origin pattern without seam allowances |

| Fabric Layout Planning | Easy | Requires some planning |

| Fabric Type Consideration | Cut for just one type of fabric | Can adjust the seam allowance for the fabric type |

| Number of Patterns Required | Several | One |

| Seam Allowance Variation | Included in the pattern | Need to remember the difference to seam and hem allowance |

| Speed of Fabric Cutting | Quick | Slower, as you need to manually add the seam allwoance |

In my own sewing practice, I usually add seam allowances at the fabric cutting stage. This allows me to reuse the same base pattern across different fabric types and seam finishes while making small design adjustments as I sew. However, if I make a pattern for someone else, then I add the seam allowances on the paper pattern with notes how much seam allowance is included.

Standard Seam Allowance Widths Used in Sewing

Most of the commercial patterns will have 1.5cm seam allowance for the patterns made for woven fabrics and 0.6cm seam allowance for knit fabrics. The hem allowance varies greatly, depending on the fashion design but it is common to see 3 cm hem allowance.

These seam allowances allow great versatile but I find them to be too generous for most projects, causing issues for curved lines, such as sleeves and armholes. I personally tend to add 1cm seam allowance for most woven fabrics and do not differentiate between side seams, shoulder seams or armholes and necklines. This is because I can get into a zone when I am sewing and would not necessary remember that I should use a different seam allowance for neckline versus side seams! 🙂

This seam allowance width works well because it eliminates the need for trimming excess fabric later and makes curved seams such as necklines and armholes easier to sew accurately.

If I intend to use the pattern for French seam finish or fabric frays easy or it is a heavy fabric, then I would add 1.5cm seam allowance. This approach provides more fabric to counter the challenges of each criteria.

For the hems I tend to use 2 cm allowance but I would increase it to intentionally affect the hang of the skirt section. Larger hem allowances are heavier and slightly pull the garment down.

Seam Allowance Cheat Sheet (Drafting & Cutting)

Here is a quick summary of all seam allowances for various garment areas, hems, fabric types.

| Garment Area | Metric | Imperial | Why This Works |

|---|---|---|---|

| Side seams | 1–1.5 cm | ⅜–⅝ in | Allows fitting adjustments and clean finishing |

| Shoulder seams | 1 cm | ⅜ in | Reduces bulk at neckline and collar area |

| Armholes | 1 cm | ⅜ in | Easier to ease and clip curves accurately |

| Necklines | 0.7–1 cm | ¼–⅜ in | Cleaner finish on tight curves |

| Waist seams | 1–1.5 cm | ⅜–⅝ in | Supports alterations and structural seams |

| Facings | 1 cm | ⅜ in | Keeps edges crisp without bulk |

| Collars & cuffs | 0.7–1 cm | ¼–⅜ in | Improves accuracy |

Adding Seam Allowance to a Paper Pattern

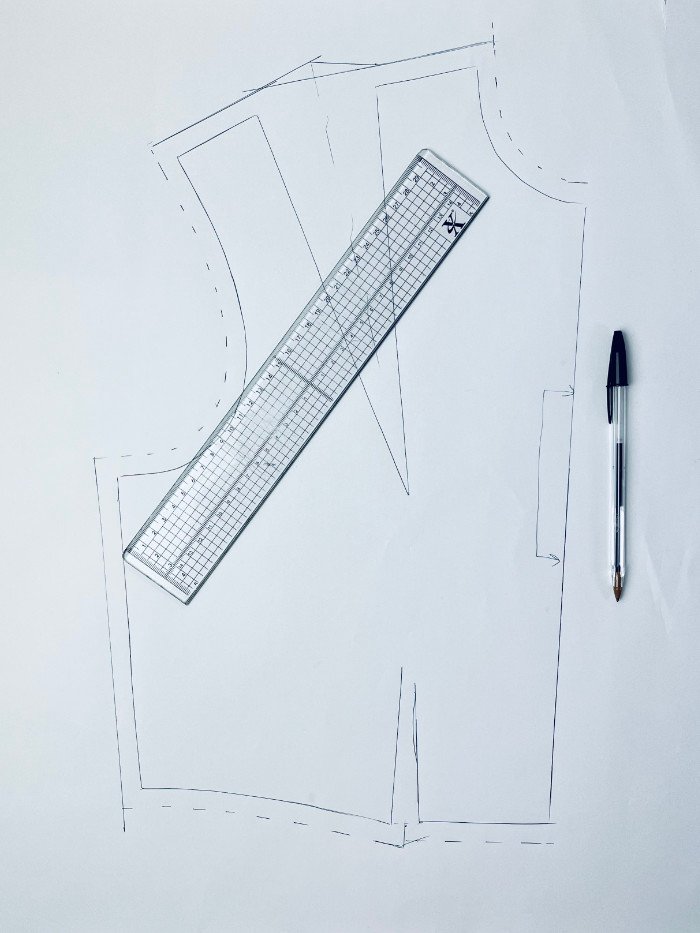

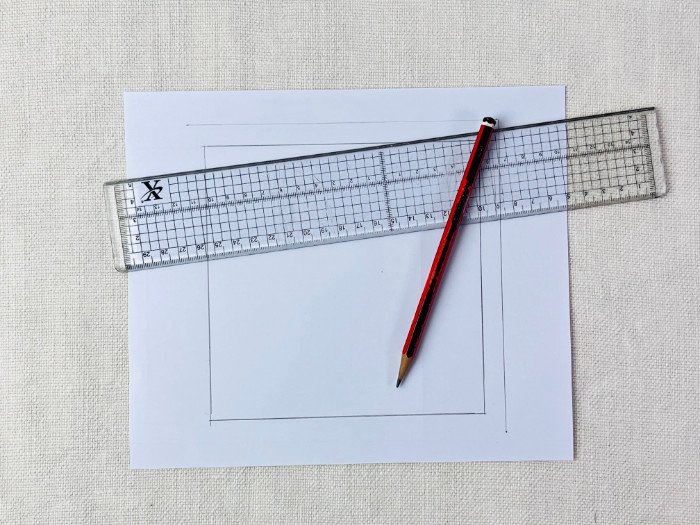

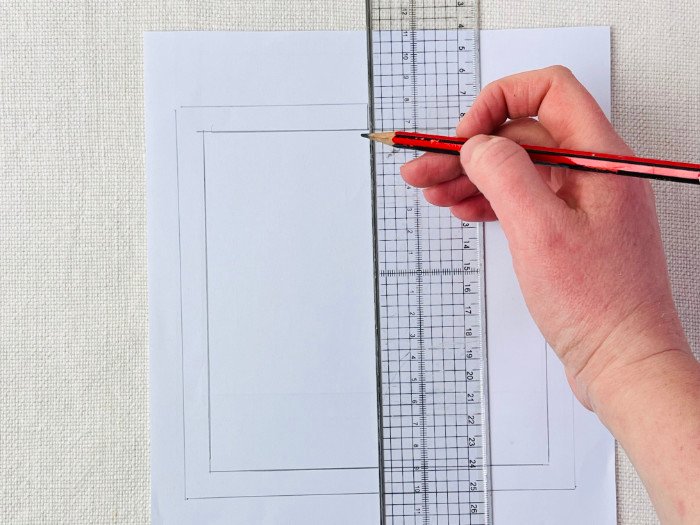

Tools Needed for Adding Seam Allowances

To add seam allowances to the paper pattern you will need a grading ruler and pen or pencil. You can use a basic ruler for this task too but the grading ruler or transparent quilting ruler will make the task of adding seam allowances quicker.

Optionally, you will also need a French curve but I personally do not use that often for adding seam allowances as I find the grading ruler is sufficient.

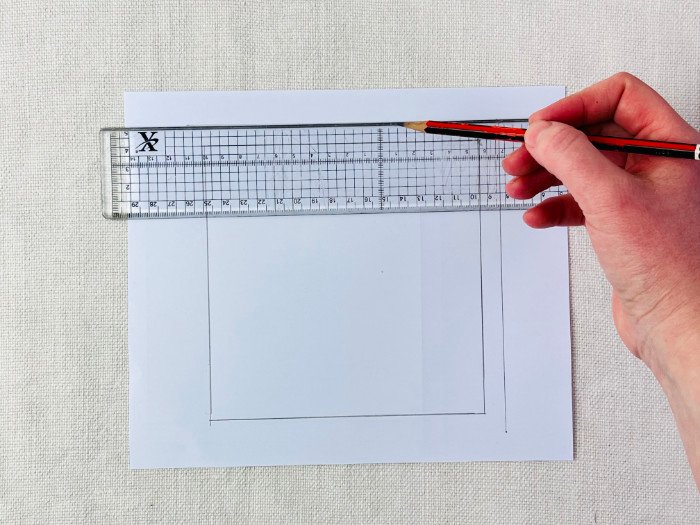

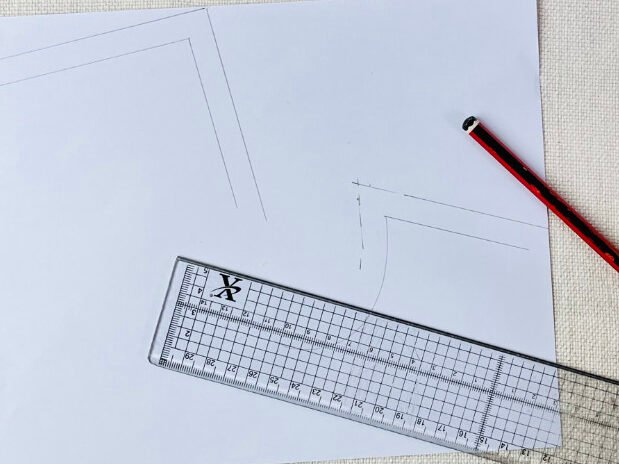

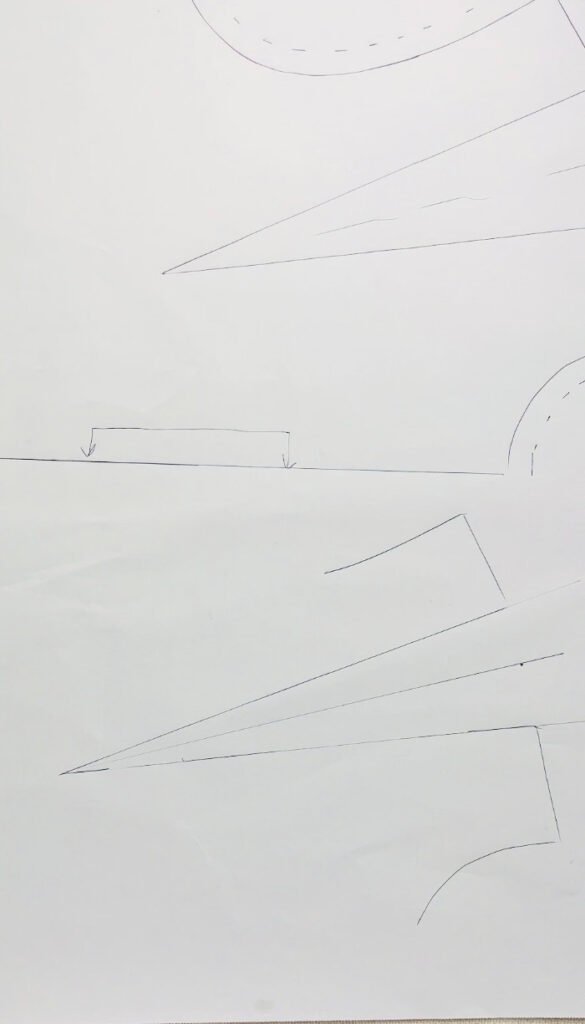

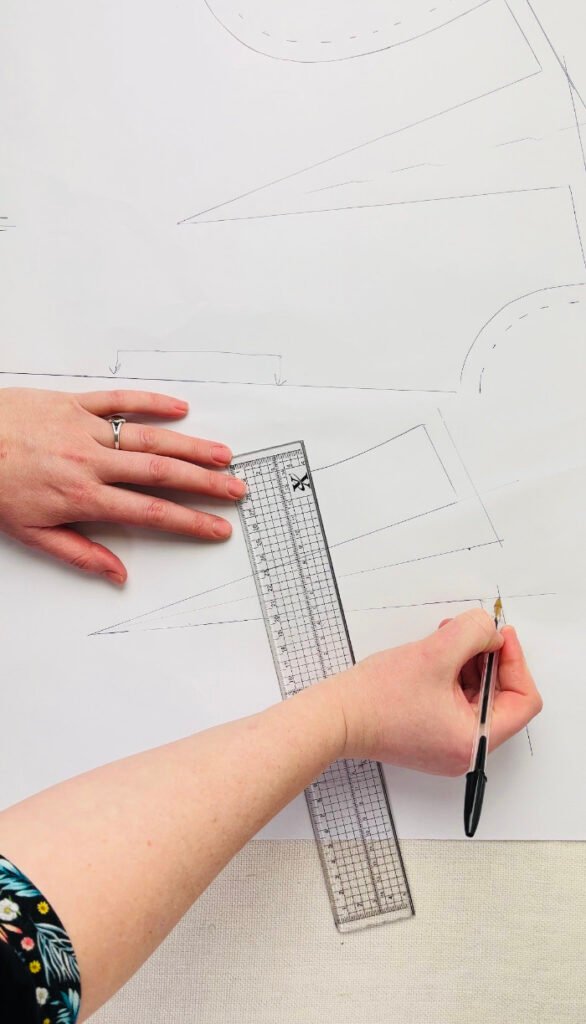

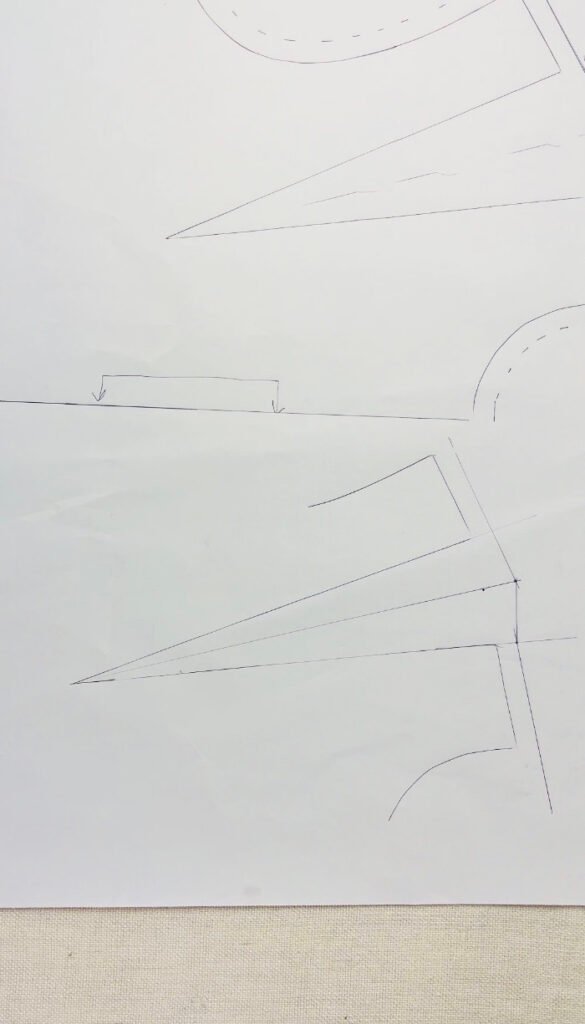

Adding Seam Allowances to Straight Seams

It is very easy to add seam allowances to straight seams. Position the grading ruler so that your chosen seam allowance width line on the grading ruler’s measurement and draw a straight line along the edge of the ruler.

In this example, I am adding one centimetre seam allowance to a straight edge.

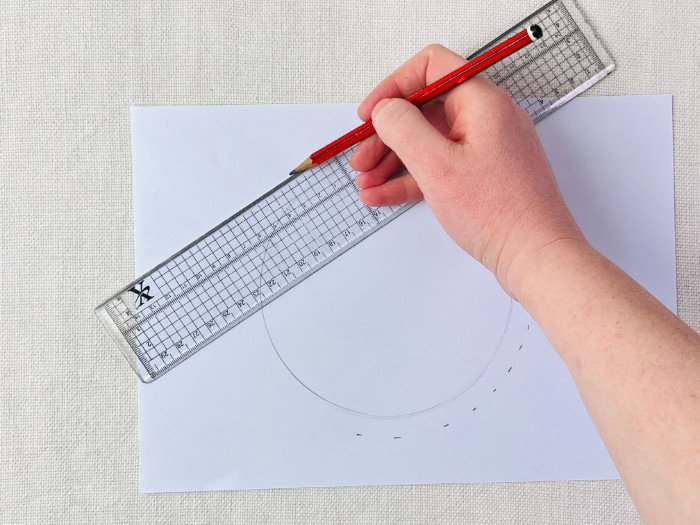

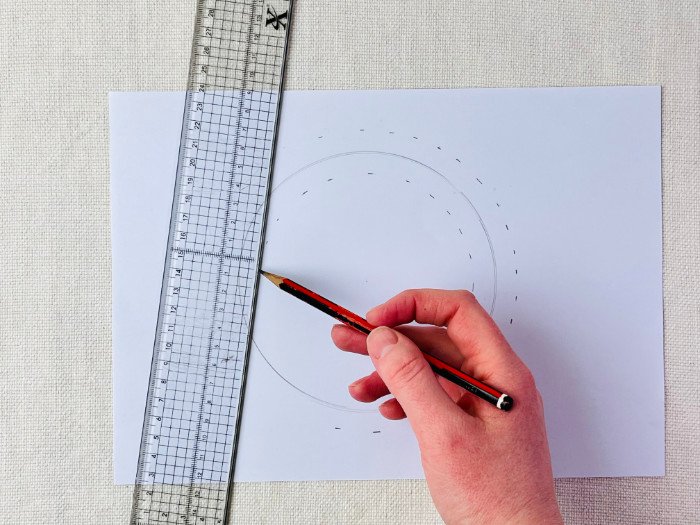

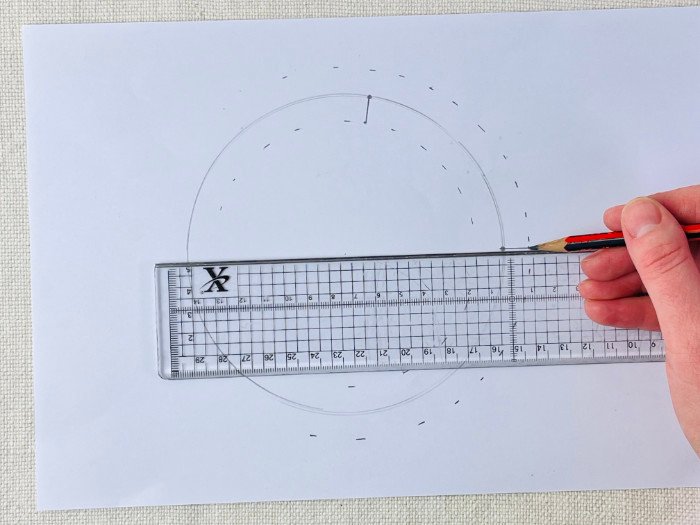

Adding Seam Allowance to Curved Seams

Undoubtedly, adding a seam allowance to a curves seam is a little more challenging than a straight curve. You need to align the grading rulers seam allowance width line with a point on a curve, making sure that the line only touches one point on the curve. Then mark a dot or short dash line on the edge of the grading ruler directly opposite of the point on the circle. This is were the grading or quilting ruler makes life ten times easier as you do not need to guess the straight corners, they are all marked on the grading ruler.

The adding of seam allowance to the curved seams is the same regardless whether it is a convex or concave curve.

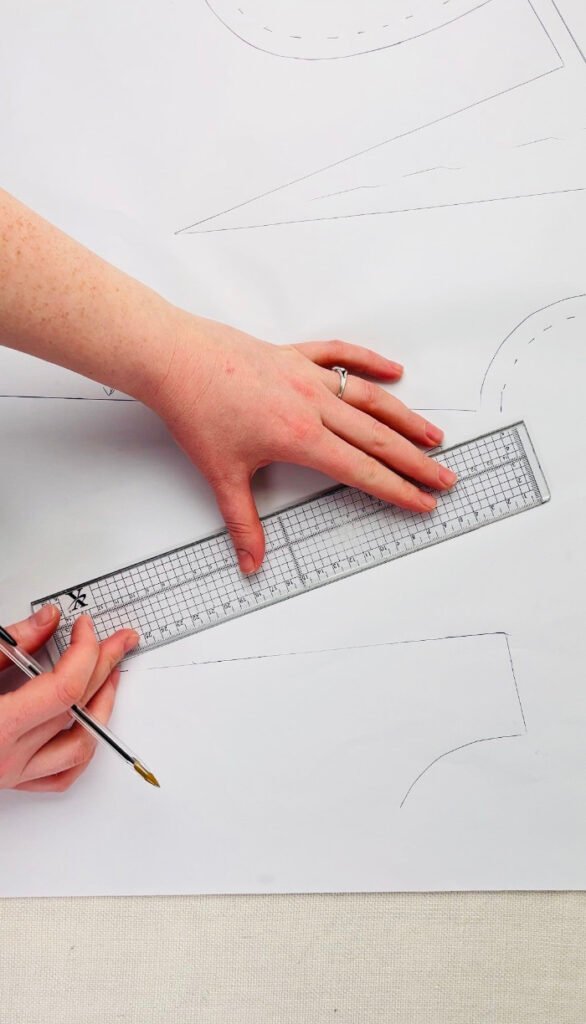

Adding Seam Allowance to Corners and Intersections

To add seam allowance to the intersection or corners, you first draw a seam allowance to the lines on either side of the intersection or corners, extending them in line with the seam allowance. I.e, for straight line, extend the seam allowance on a straight line past the corner. For the curved line, extend the seam allowance to continue the curved line.

If you measured from the corner to corner, the seam allowance at the points, corners and intersections would be larger than the seam allowance on the sides. This is how it should be. Once you sew the seams, you will start from the edge of the fabric with the same seam allowance and these points will be stitched along the seam line. The protruding corners can later be cut off.

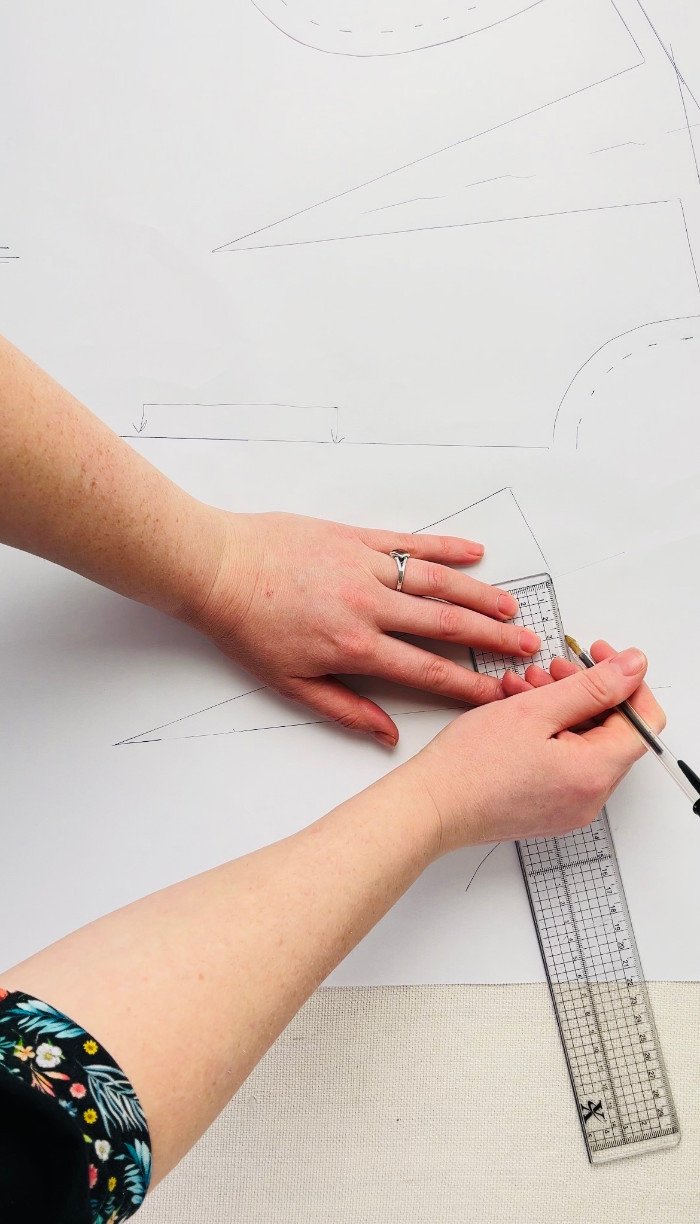

Adding Seam Allowance to Darts

To add a seam allowance to the base of the dart, first extend the sides of the darts in a straight line.

Then mark a middle point of the dart at its opening.

Then connect the middle point of the dart opening with the dart end point with a straight line, extending it past the middle point.

Next, draft the seam allowances to the lines on either side of the dart, following the instructions for a straight or curves seam. Extend these lines to cross with line drawn from the middle of the dart.

One seam allowance will connect with the dart’s middle line higher than the other. This point will be the highest point for your dart seam allowance. Connect this highest point with the dart side and seam allowance intersection point on the other lower side to complete the seam allowance for a dart.

Transferring Notches and Markings

Notches and markings on the seam lines indicate a connection points that need to be matched with another pattern piece. To transfer a marking to a seam allowance, follow the themes for adding seam allowance to curved lines.

Align the seam width line on the grading ruler with the marking and mark a dot on the seam allowance. Connect the dots with a straight line.

Adding Seam Allowance Directly on Fabric

When adding seam allowances directly to fabric, use the same measuring principles as you would on paper, but take extra care to prevent fabric distortion during marking.

You can add seam allowances directly on most basic garment patterns, and it works the best on straight and uncomplicated curved seams.

To avoid distortion, make sure that the sewing pattern is securely placed on the fabric, pinned in place or weighted down with pattern weights. Mark seam allowances lightly without pulling or stretching the fabric, as distortion at this stage can affect garment fit. I find that the chalk is not the best tool for most fabrics as it is quite rough and pulls the fabric, distorting it. I tend to use a sliver of soap with sharp corners for dark fabrics and heat erasable pen with light fabrics. Both options glide over the fabric and are easy to remove.

Avoid adding seam allowances directly on the fabric if the pattern has a lot of small curved line notches that need to be matched up neatly. Adding seam allowances directly on a fabric for princess seams on a floaty rayon fabric will be challenging but not impossible for a beginner.

How Fabric Type Affects Seam Allowance

Different types and weights of fabrics will require different seam allowances. Let’s look at common dress making fabrics in turn.

Lightweight Cotton and Lawn

Lightweight cotton and lawn fabrics do not fray as much as the fibres are smaller. They both press easily and comply with most fabric manipulations. For that reason, the seam allowance can be smaller and 1 cm (3/8 in) wide seam allowance are my go to solution for basic seams.

A muslin or double gauze fabric is a lightweight fabric that frays a lot. For these I use 1.5cm (5/8 in) allowance.

Lightweight Rayon Fabric

Contrary to lightweight cotton and lawn fabrics, the rayon fabric frays in the wash. For rayon fabrics it is best to use 1.5cm (5/8 in) seam allowance and go for French seam finish to prevent the seams from completely fraying away through the wash.

Mid-weight Cotton and Linen

Midweight cotton and linen are a little more sturdier and not as pliable to manipulations. They can fray a little bit more under a lot of pulling or stretching but stay reasonably stable. For these fabrics you can increase the seam allowance to 1.5cm (5/8 in) and trim the excess once the seams are finished.

I personally assess how easily the midnight fabrics fray by rubbing the raw edge. If it does not fray match, I stick to 1cm (3/8 in) seam allowance but if the raw edge unravels a lot, then I increase to 1.5cm (5/8 in).

Hemp Fabric

Woven hemp fabric has thick fibres that are not weaves as dense as light weight or midnight cotton. This can lead to fraying, therefore, to strengthen the seams, go for 1.5cm (5/8 in) seam allowances. Hemp knit fabrics do not fray, so a standard 1 cm (3/8 in) seam allowance is sufficient and helps reduce bulk.

Just make sure you have prewashed the fabric so that the final garment does not shrink and add extra pressure on the seams.

Wool

Woven wool fabric is quite thick fabric that maintains its structure. Depending on the weave, wool fabric can fray easily on herringbone or tweed weave or be quite stable on melton or boiled wool. Regardless of the weave, you will need to add more seam allowance to wool to allow fabric manipulation for pressing the seams open or reshaping the garment with a steam.

To be on the safe side, to use 1.5cm – 2cm (5/8 to 3/4 in) seam allowance for the wool fabrics.

Heavy Fabrics

Heavy fabrics, such as denim and canvas will require larger seam allowances as these fabrics usually require different seam finishes for strong seams. While I have made dresses from cotton twill with just 1 cm (3/8 in) seam allowance, I would use 1.5cm (5/8 in) seam allowance on canvas and up to 2cm (3/4 in) seam allowance on denim.

Remember this

Always prewash and dry fabric before cutting to prevent post-construction shrinkage that can stress seams.

Here is a quick summary of each fabric type and their seam allowance requirements

| Fabric Type | Metric | Imperial | Reason |

|---|---|---|---|

| Lightweight cotton / lawn | 1 cm | ⅜ in | Minimal fraying, presses flat |

| Midweight cotton | 1–1.5 cm | ⅜–⅝ in | Balanced strength and ease of sewing |

| Linen | 1.5 cm | ⅝ in | Frays easily, benefits from wider allowance |

| Hemp (woven) | 1.5 cm | ⅝ in | Thick fibres, stronger seams |

| Hemp (knit) | 1 cm | ⅜ in | Reduces bulk while retaining stretch |

| Wool (woven) | 1.5–2 cm | ⅝–¾ in | Allows pressing and reshaping |

| Denim / canvas | 1.5–2 cm | ⅝–¾ in | Supports strong seams and topstitching |

Knit vs Woven Seam Allowance Differences

Knit fabrics use narrower seam allowances as the knit fabrics do not fray and they stretch, putting less pressure on the seams. For this reason, the knit fabrics will have seam allowances between 0.7 – 1cm (1/4 – 3/8 in).

If you are using an overlocker to sew the knit garments, then use the narrower 0.7cm (1/4 in) seam allowance. For seams done on the sewing machine with zig zag stitch, choose the larger 1cm (3/8 in) seam allowance to allow the space for the zig zag stitch and prevent the edge of the fabric being chewed by the sewing machine’s feed dogs.

Hems, Seam Finishes & Seam Allowance Planning

Regardless whether you are adding the seam allowance onto a paper pattern or directly on the fabric, you need to consider the seam finishes.

French and flat felled seams will require larger seam allowance compared to overlocked seams. I recommend 1.2 – 1.5cm (1/2 – 5/8 in) seam allowance for French seams and 2cm (3/4 in) seam allowance for flat-felled seams while overlocked seams do not need more than 1cm (3/8 in).

Do not forget about the hems either. A turned up hem will require wider allowance compared to faced hems.

Common Seam Allowance Mistakes (and How to Avoid Them)

Below are common seam allowance mistakes and practical ways to avoid them when drafting or cutting sewing patterns.

- Forgetting seam allowance on curves. Start by adding seam allowances on the curves first.

- Mixing seam allowance width. While it is ok to have varying seam allowances on the sewing pattern, they should always match with the other side. I.e., sleeve crown seam allowance should be the same width as the armhole seam allowance. To avoid the mistake of having seam allowances that do not match in pairs, add the different seam allowance width on all patterns first and then complete the rest of the pattern in your chosen standard seam allowance.

- Not accounting for fabric fraying. Add the suggested upper end of seam allowance.

- Adding seam allowance twice. Make a habit of clearly marking on your pattern whether seam allowances are included and the exact width used. If a seam differs from the rest of the garment, make a note on the pattern near the seam that has different seam allowance width.

Seam Allowance Quick Reference Cheat Sheet

You can download the quick reference cheat sheet by subscribing to my newsletter.

FAQ Section

Conclusion

In this guide, you learned when and how to add seam allowances to sewing patterns, how fabric type affects seam allowance width, and how to choose allowances that support both construction and longevity. Save or bookmark this page as a reference when drafting or cutting patterns for natural fibre garments.

If you found this guide helpful, you may also like my tutorials on drafting a basic bodice block and sewing a beginner-friendly wrap skirt, where seam allowance planning plays a key role in fit and finish.